Active electric filter in atmospheric adsorptive installation

A power filter and adsorption technology, applied in active power filtering, cooling/ventilation of substation/switchgear, electrical components, etc., can solve the problems of ground damage in the machine room, small working space, filter aging, etc., to achieve Reduce the difficulty of maintenance and installation, increase the operable space, and improve the efficiency of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

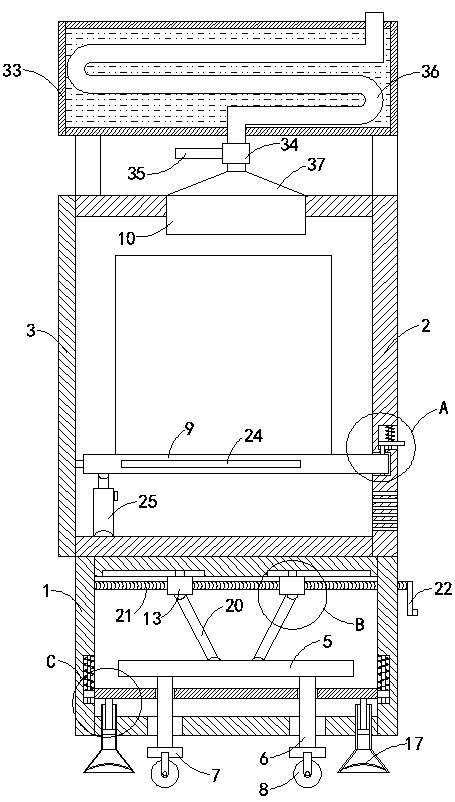

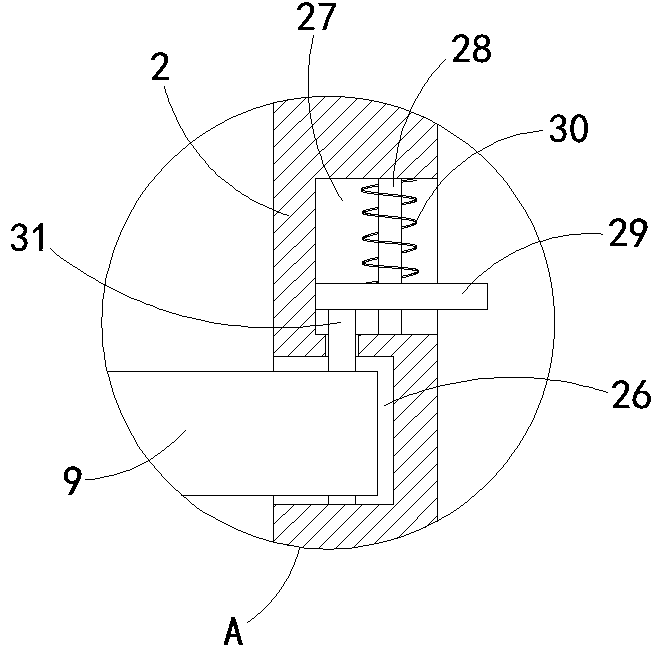

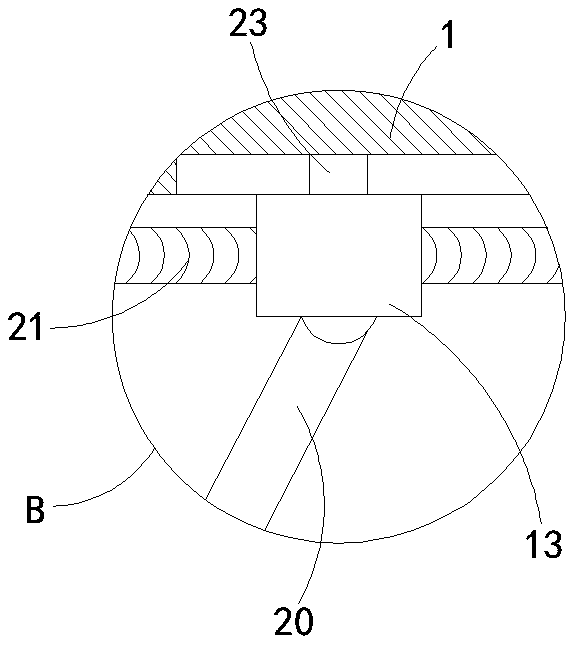

[0030] like Figure 1-7 As shown, an active power filter installed by air pressure adsorption includes a cabinet body 1 and a cabinet body 2 fixedly connected to the upper end of the cabinet body 1, a side door 3 is hinged on the side wall of the cabinet body 2, and the inside of the cabinet body 2 is installed There is a filter device, a movable plate 4 is provided in the box body 1, a reset mechanism for resetting the movable plate 4 is provided on the side wall of the box body 1, a support mechanism is provided at the lower end of the movable plate 4, and the upper side of the movable plate 4 A horizontal plate 5 is provided, the four corners of the lower end of the horizontal plate 5 are fixedly connected with supporting columns 6, the lower ends of the supporting columns 6 are set through the movable plate 4 and the bottom surface of the box body 1, and the lower ends of the supporting columns 6 are fixedly connected with mounting seats 7, The bottom surface of the box bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com