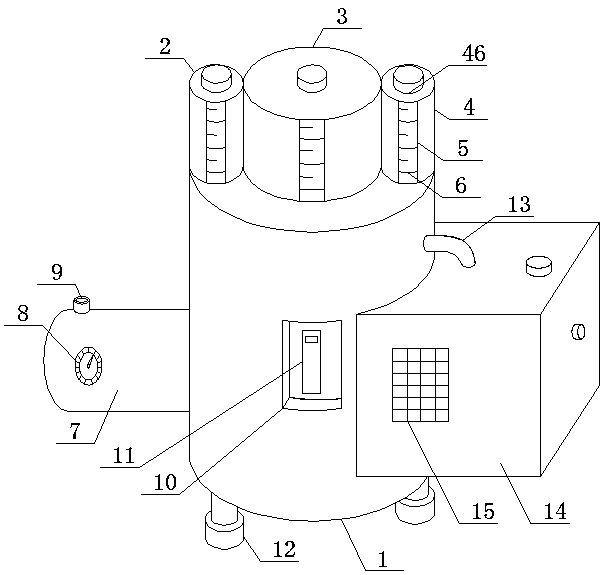

Chloro-methoxy fat diethylene glycol dinitrate production equipment

A technology for production equipment of chloromethoxy fatty acid methyl ester, which is applied in the field of production equipment of chloromethoxy fatty acid methyl ester, can solve problems such as staff injury, waste, and raw material dripping, and achieve environmental protection and practical Strong and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

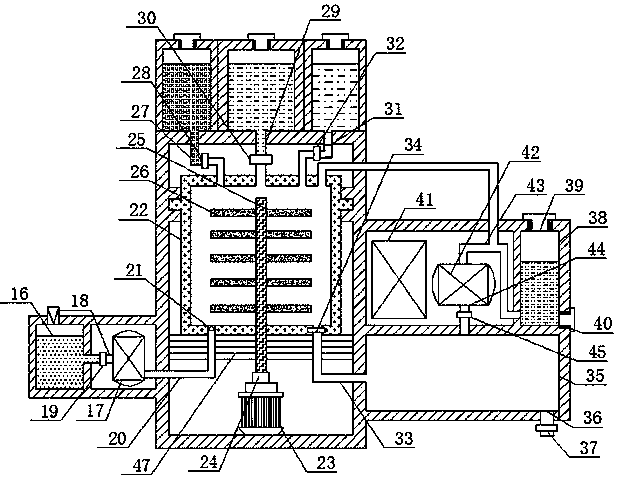

[0025] As a preferred embodiment of the present invention, the motor 23 is a three-phase asynchronous motor.

[0026] As a preferred embodiment of the present invention, the storage battery 41 is connected to the controller 15 through wires, and the controller 15 is connected to the air pump one 17, the air pump two 42, the motor 23, the heating plate 47, the pH tester 11, Solenoid valve one 19, solenoid valve two 28, solenoid valve three 30, solenoid valve four 32, solenoid valve five 34 and solenoid valve six 45 are connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com