Cement stirrer

A cement mixer and mixer technology, applied in cement mixing devices, clay preparation devices, mixing operation control devices, etc., can solve the problems of low work efficiency, unsatisfactory, poor stability, etc., achieve reasonable structural design, speed up mixing speed, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

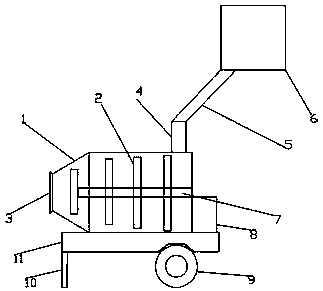

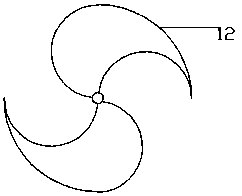

[0018] figure 1 with figure 2 A specific embodiment of the present invention is shown: a cement mixer, including a mixer body composed of a mixing drum 1, a base 11 and a feeding table, the mixing drum 1 is a cylindrical drum, and the front and rear ends of the mixing drum 1 are respectively provided with The discharge port 3 and the feed port 4, and the diameter of the discharge port 3 and the feed port 4 are smaller than the diameter of the mixing drum 1, the stirring drum 1 is provided with a stirring shaft 7, and one end of the stirring shaft 7 is connected with the 8 rotating shafts of the motor, stirring Several layers of stirring layers 2 are arranged on the shaft 7, and there is a certain distance between each layer of stirring layers 2. The stirring layer 2 is composed of at least two stirring blades 12, and the closer the stirring blades 12 to the discharge port 3 are, the finer the quantity is. The more, the feeding table is located at the rear end of the mixing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com