SCRIBING WHEEL and PRODUCTION METHOD FOR SCRIBING WHEEl

A manufacturing method and scoring wheel technology, applied to other manufacturing equipment/tools, manufacturing tools, glass manufacturing equipment, etc., can solve the problems of inability to form cracks, infeasibility, wear and tear, etc., so as to inhibit the formation of cracks, reduce the formation of gaps, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Hereinafter, embodiments of the present invention will be described using the drawings. However, the embodiment shown below is merely an example for actualizing the technical idea of the present invention, and there is no intention to limit the present invention to this embodiment. The present invention is of course applicable to other embodiments included in the claims.

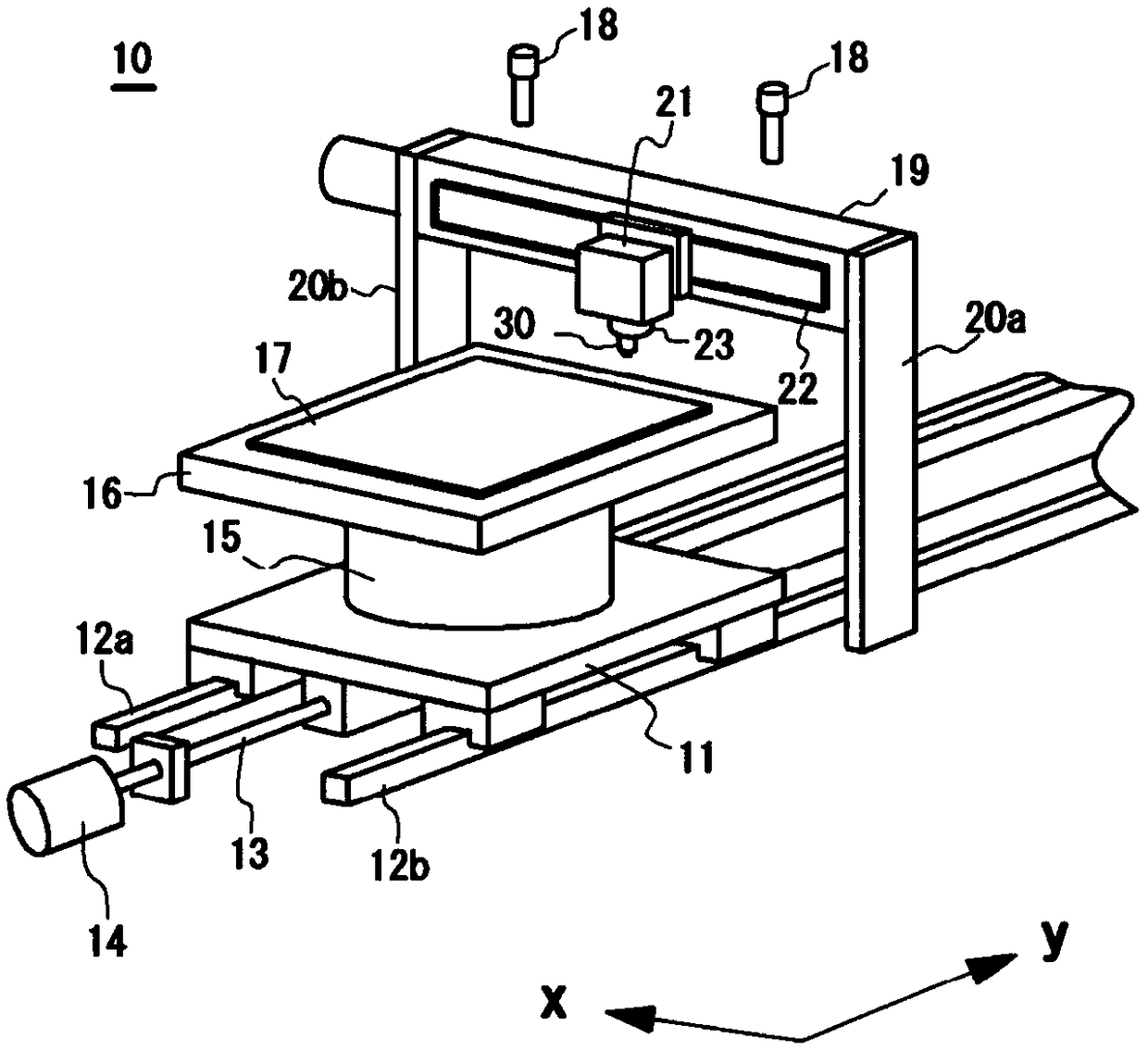

[0060] figure 1It is a schematic diagram of a scribing apparatus 10 according to an embodiment of the present invention. The scribing device 10 includes a mobile station 11 . The moving table 11 is screwed with the ball screw 13, and the ball screw 13 is rotated by the drive of the motor 14, thereby moving in the y-axis direction along the pair of guide rails 12a and 12b.

[0061] A motor 15 is provided on the upper surface of the mobile stand 11 . The motor 15 rotates the upper table 16 in the xy plane and positions it at a predetermined angle. A tempered glass substrate 17 as a scr ibe object...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com