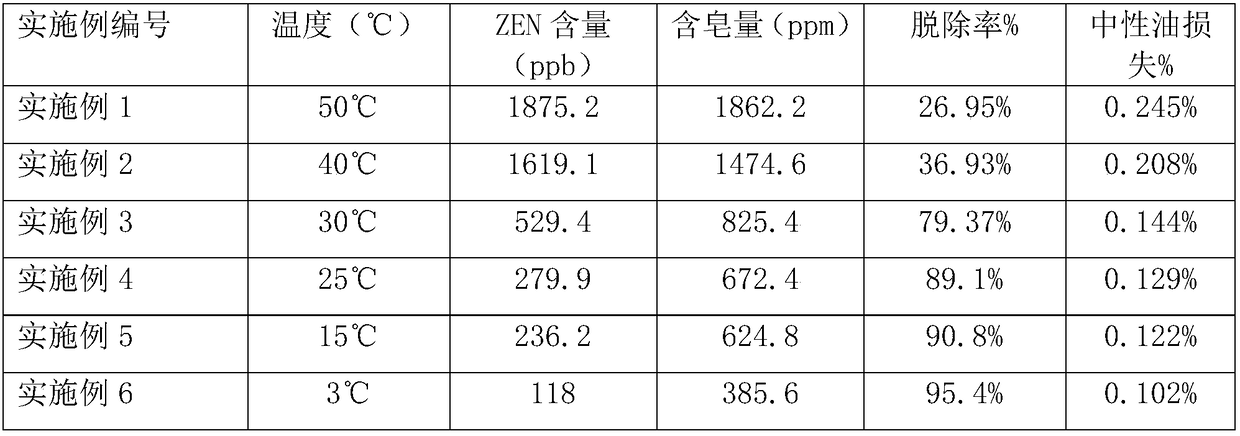

Grease processing technology

A technology for oil processing and oil, applied in the direction of oil/fat refining, fat production, etc., can solve the problems of large alkali consumption, insignificant reduction effect of zearalenone, and high loss of neutral oil, so as to reduce zearalenone. The effect of the content of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 17-21

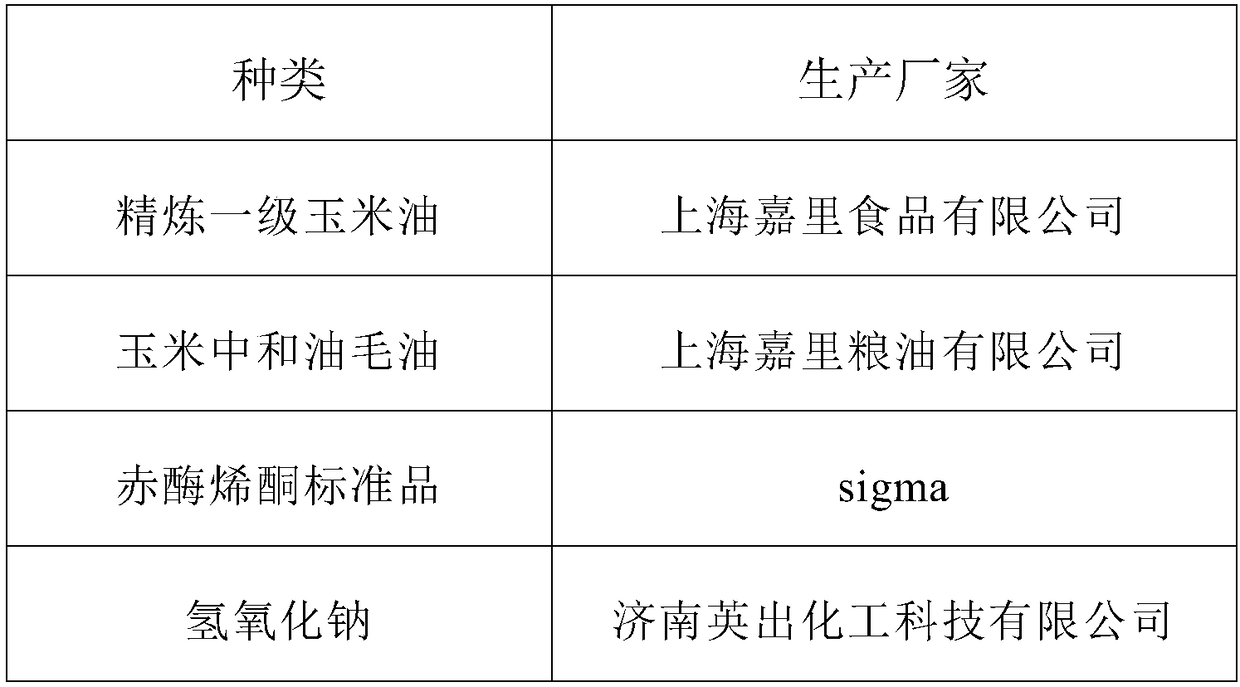

[0122] Embodiment 17-21 The influence of the amount of alkali added on the reduction effect of erythralenone

[0123] Take 5 parts of the same batch of refined first-grade corn oil 200mL (the content of erythralenone is 2567ppb) in a beaker, place it on a temperature-controlled stirring table, adjust the reaction temperature to 6°C, and add alkali according to Table 4. The concentration is 20%. NaOH aqueous solution, stirred and reacted for 6 hours, filtered respectively, took a sample and measured the content of erythralenone in every part of corn oil after the treatment, and the experimental results were as follows:

[0124] Table 4 The effect of the amount of alkali added at 6°C on the reduction effect of erythralenone

[0125]

[0126] As can be seen from Table 4, under the same conditions of lye concentration and reaction time, the higher the amount of alkali added, the lower the content of erythralenone. The content basically tends to be stable, but the loss of neutral...

Embodiment 22-27

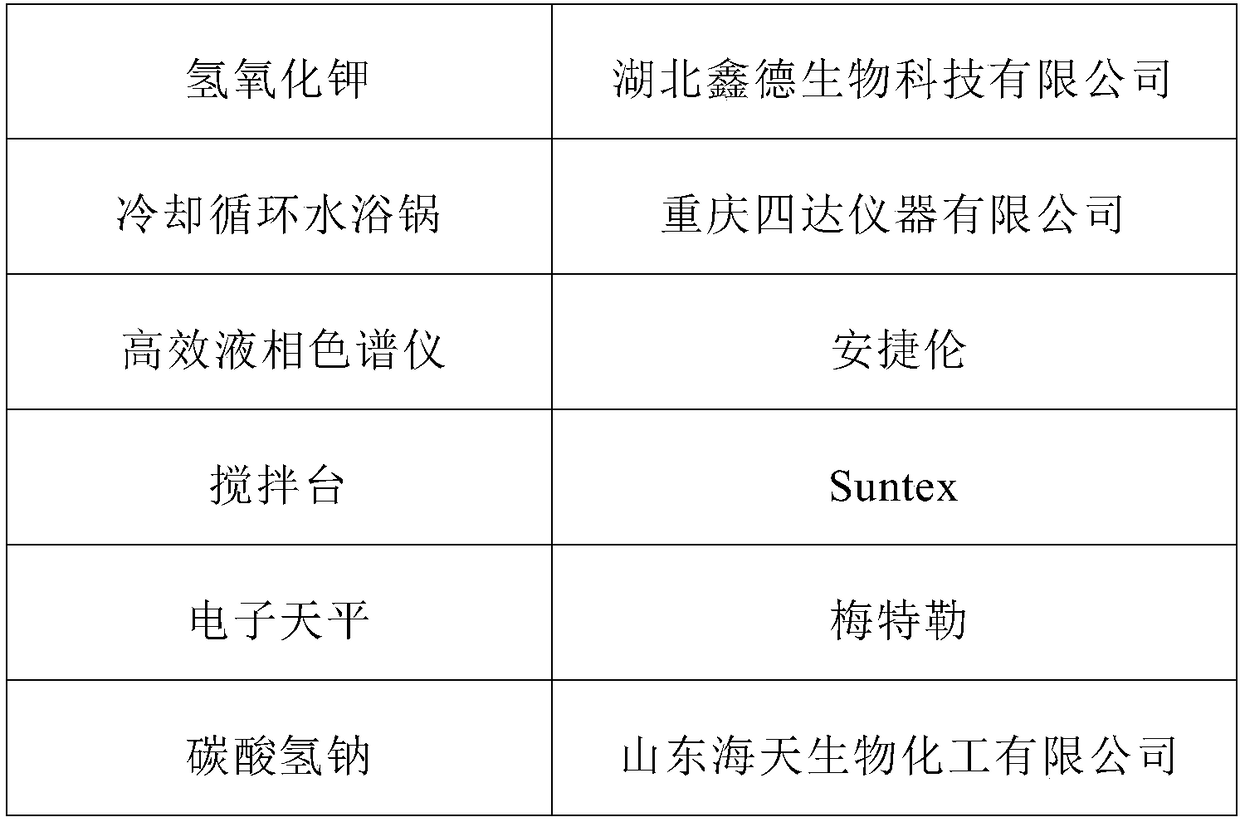

[0127] Embodiment 22-27 The influence of alkali concentration on the reduction effect of erythralenone

[0128] Take 6 parts of the same batch of refined first-grade corn oil 200mL (the content of erythralenone is 2567ppb) in a beaker, place it on a temperature-controlled stirring table, adjust the reaction temperature to 6°C, add NaOH aqueous solution according to the alkali concentration in Table 5, and add alkali Amount is 0.03% (calculated as 0.055g with NaOH) of grease weight, stirring reaction 6 hours, filter respectively, take a sample and measure the content of erythralenone in every part of corn oil after processing, experimental result is as follows:

[0129] Table 5 The effect of alkali concentration on the reduction effect of erythralenone at 6°C

[0130]

[0131] It can be seen from Table 4 that under the same conditions of alkali addition and reaction time, the content of erythralenone does not change much with the increase of lye concentration and can be kept...

Embodiment 35-37

[0142] Embodiment 35-37 The influence of other alkali on removing erythralenone

[0143] Take 200mL of 3 parts of refined first-grade corn oil from the same batch (the content of erythralenone is 2567ppb) in a beaker, place it on a temperature-controlled stirring table, adjust the reaction temperature to 6°C, and add the concentration of alkali according to Table 8. The aqueous solution of 20% alkali, the amount of alkali added is 0.03% (counted as 0.055g in NaOH) of grease weight, stirred and reacted for 6 hours, filtered respectively, sampling and measuring the content of erythralenone in every part of corn oil after processing, The experimental results are as follows:

[0144]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com