Low-noise efficient gas turbine exhaust system

A technology for gas turbines and exhaust systems, applied in mechanical equipment, engine components, engine functions, etc., to achieve the effect of reducing noise, reducing noise, and uniform impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

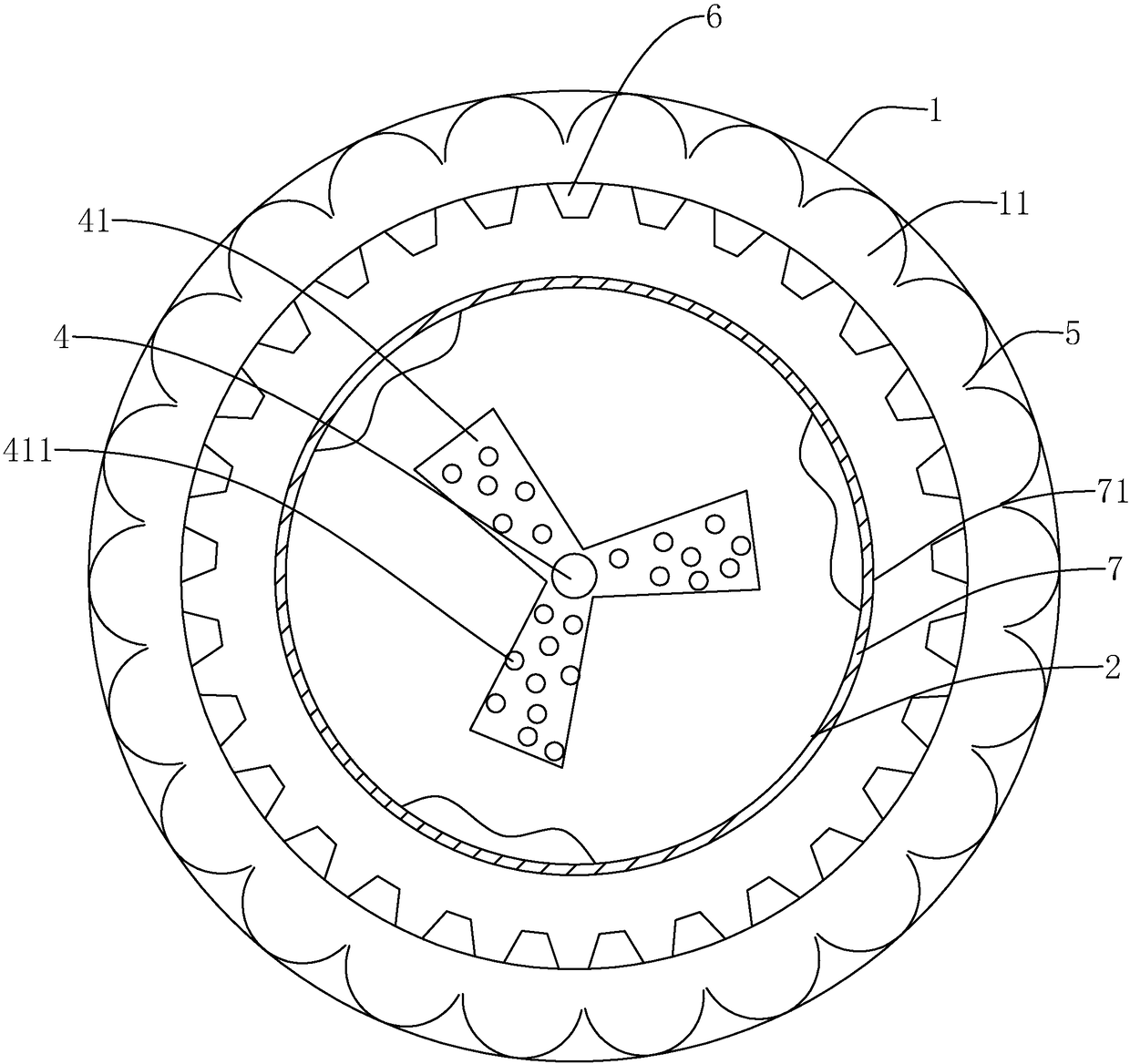

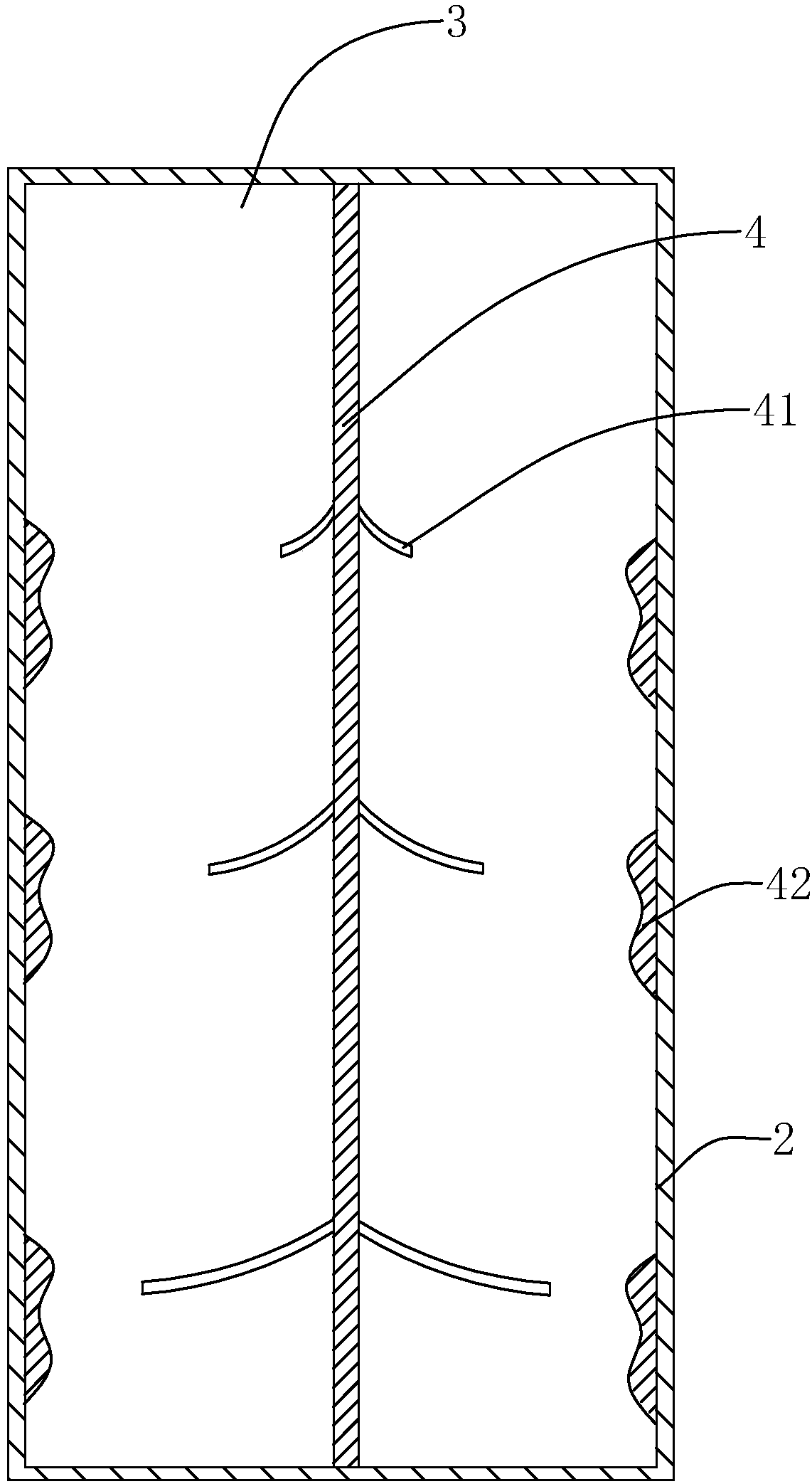

[0025] Embodiment: a kind of low-noise high-efficiency gas turbine exhaust system, such as figure 1 and 2 As shown, it includes an exhaust pipe. The exhaust pipe includes an outer pipe 1 and an inner pipe 2. The inner pipe 2 communicates with the exhaust outlet 3 of the gas turbine. The exhaust gas from the gas turbine is discharged through the inner pipe 2. The inner pipe 2 is provided with a A slow-flow device for diverting and buffering exhaust gas to reduce noise from the root. There is a sound-absorbing layer 11 between the outer pipe 1 and the inner pipe 2. The sound-absorbing layer 11 is made of foamed aluminum fiber, and the foamed aluminum fiber The porosity is 65%~75%, which is used to absorb noise, and the combination of the two can greatly reduce noise.

[0026] Such as figure 2 As shown, the slow flow device includes a fixed rod 4 arranged in the middle of the inner tube 2, and several buffer pieces are arranged on the fixed rod 4. Hole 411, the inside of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com