Method and structure for eliminating noise of torsion bar system

A torsion bar and noise technology, applied in the field of rail vehicles, can solve problems such as noise, and achieve the effects of improving wear resistance, uniformly increasing compressive modulus, and reducing friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

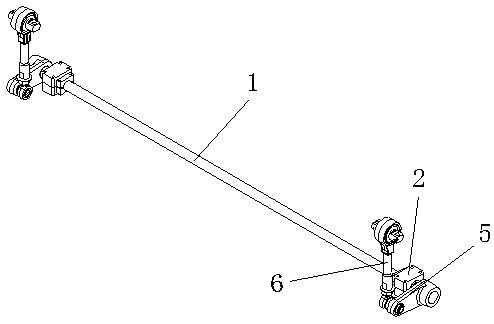

[0043]A structure for eliminating the noise of the torsion bar system, including a support seat 2, a support ball joint 3 and a torsion bar shaft 1, the support ball joint 3 is arranged in the support seat 2, the torsion bar shaft 1 passes through the support ball joint 3, and the support seat 2 And the support ball joint 3 adopts a two-lobe structure; in this embodiment, the PTFE self-lubricating coating with a low friction coefficient is sprayed on the position where the torsion bar shaft 1 contacts with the support ball joint 3 to improve the noise generated during operation. The material is The friction pair formed between the nylon 66 supporting ball joint 3 and the torsion bar shaft 1 with PTFE self-lubricating coating on the surface has a friction coefficient that is reduced to 0.1-0.4 compared with the original structure, and the torsion bar system of this structure is on-line There is no noise when starting up, and there will be noise during subsequent operation, but i...

Embodiment 2

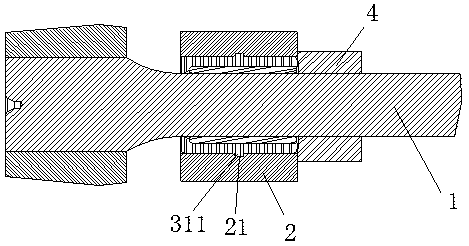

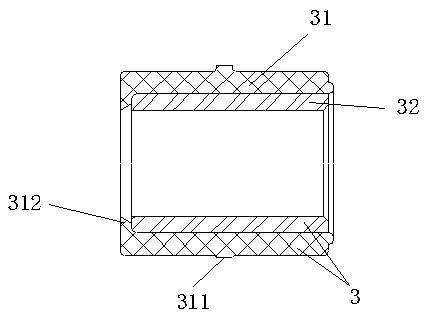

[0045] Such as figure 2 As shown, in the present embodiment, nylon 66 is used as the spherical joint casing 31 supporting the spherical hinge 3, and the PET wear-resistant layer 32 with a low friction coefficient is vulcanized inside the spherical hinge casing 31, and the inside is the supporting ball of the PET wear-resistant layer 32. Compared with the original structure, the friction coefficient of the friction pair formed between the hinge 3 and the torsion bar shaft 1 sprayed with PTFE self-lubricating coating on the outside is greatly reduced to 0.05-0.2. The reduction of friction between the supporting ball joint 3 and the torsion bar shaft 1 can not only avoid noise, but also reduce the wear between the supporting ball joint 3 and the torsion bar shaft 1, prolonging the service life of the torsion bar system.

Embodiment 3

[0047] In this embodiment, the outer diameter of the supporting spherical hinge 3 is slightly larger than the inner diameter of the supporting seat 2, and the supporting spherical hinge 3 is pre-compressed and has an interference fit with the supporting seat 2, and the wear-resistant layer 32 of the supporting spherical hinge 3 and the torsion bar shaft 1 with a slight gap between them. The interference fit between the supporting spherical hinge 3 and the supporting seat 2 after pre-compression avoids the gap between the supporting spherical hinge 3 and the supporting seat 2 in the original structure, so that the torsion bar shaft 1 drives the supporting spherical hinge 3 and the supporting seat during the movement 2 produces relative motion, and the friction between the supporting ball joint 3 and the supporting seat 2 also makes the range of motion of the torsion bar shaft 1 too large, resulting in impact noise; a small gap is set between the supporting ball joint 3 and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com