An online error measurement system and method for laser dot-matrix CNC machine tools

A technology of laser dot matrix and CNC machine tools, applied in general control systems, control/regulation systems, program control, etc., and can solve problems such as error measurement and manual completion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is described in detail below in conjunction with accompanying drawing.

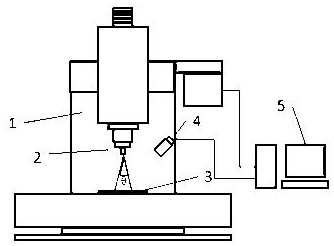

[0042] Such as figure 1 As shown, a three-axis CNC machine tool online error testing system based on laser dot matrix includes a CNC machine tool 1, a laser dot matrix generator 2, a grid positioning board 3, an industrial camera 4, and a computer 5.

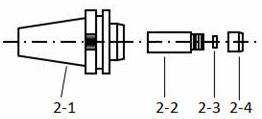

[0043] Such as figure 2 As shown, the laser dot matrix generating device 2 is made up of a handle 2-1, a laser generating device 2-2, a grating 2-3 and a grating fixing device 2-4, wherein the grating can convert the single beam light generated by the laser generator into A 3×3 array of nine beams evenly arranged, in which the outermost two beams of each row form an angle of θ with each other. The laser dot matrix generating device 2 is similar to the common cutting tool, and can be placed in the CNC machine tool in the disc and changed to the main shaft by the tool changer provided by the CNC machine tool.

[0044] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com