A Model Predictive Direct Power Control Method Based on Three Vectors

A model prediction and power control technology, applied in the field of electric transmission, can solve the problems of complex design of output filter and unfixed switching frequency, etc., and achieve the effect of suppressing power ripple and reducing current harmonic distortion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The technical solution of the present invention will be further introduced below in combination with specific embodiments.

[0061] This specific embodiment discloses a three-vector-based model predictive direct power control method, including the following steps:

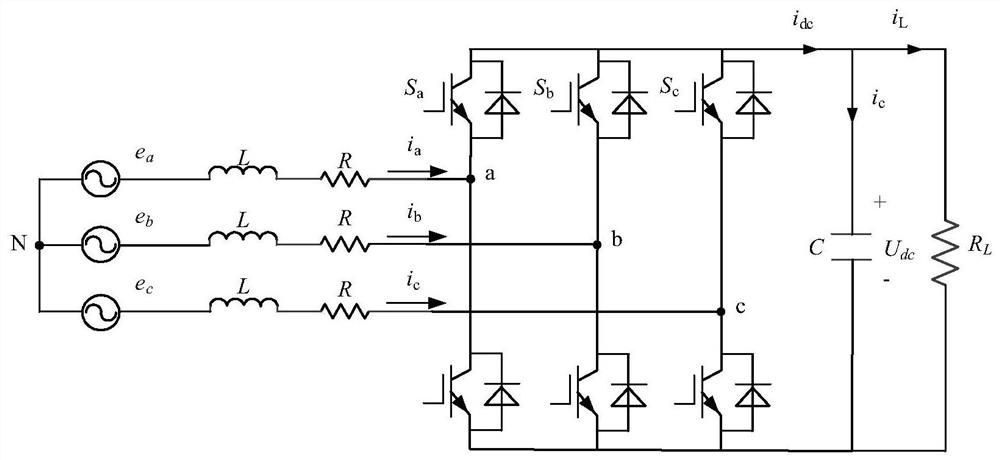

[0062] S1: collect the symmetrical three-phase current i of the three-phase voltage-type PWM rectifier a i b i c , DC bus voltage U dc and load current i L ;

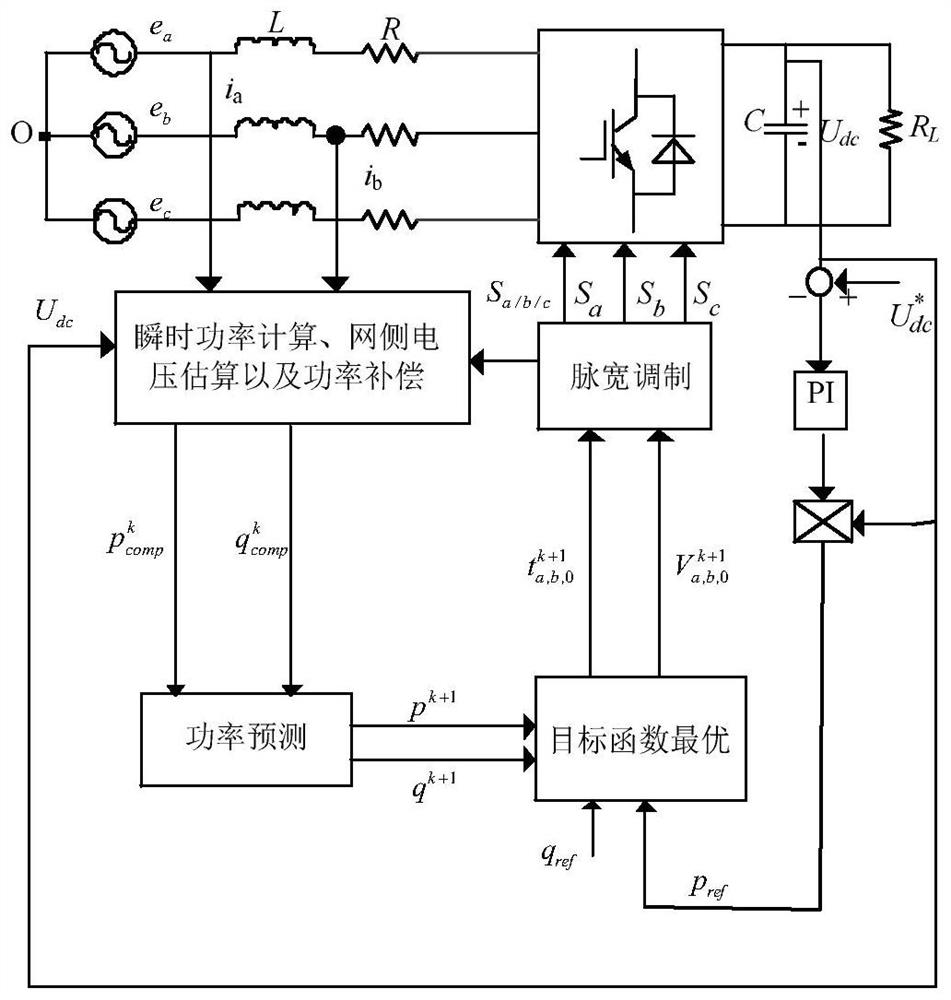

[0063] S2: DC bus voltage U dc with a given DC bus voltage U ref The difference is output by the PI regulator, the output value and the DC bus voltage U dc The product of the given active power p ref ;Given reactive power q ref = 0;

[0064] S3: According to the symmetrical three-phase current i a i b i c and the six switching tube states of the three-phase voltage-type PWM rectifier to obtain the virtual flux linkage ψ, active power p, reactive power q and the component e of the grid voltage in the αβ coordinate system α and e β ;

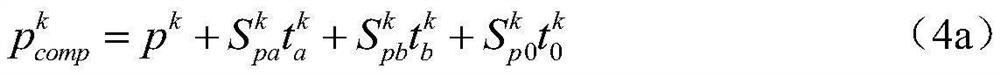

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com