Control system and control method for blowing and cleaning self-unloading equipment for high-viscosity pharmaceutical capsules

A high-viscosity, self-unloading technology, applied in cleaning methods and tools, cleaning methods using tools, cleaning methods using gas flow, etc., can solve the problems of low degree of automation control, large error rate, single, etc., to achieve process The effect of reasonable design and strict control logic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

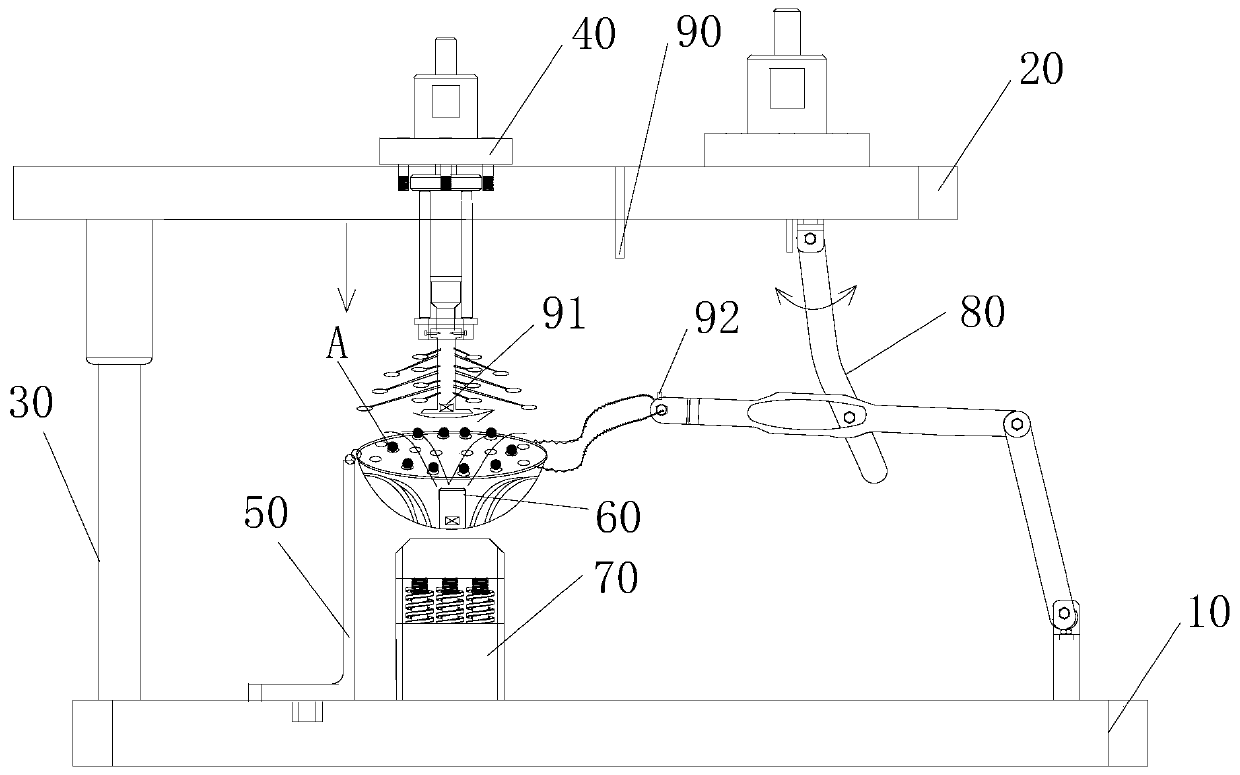

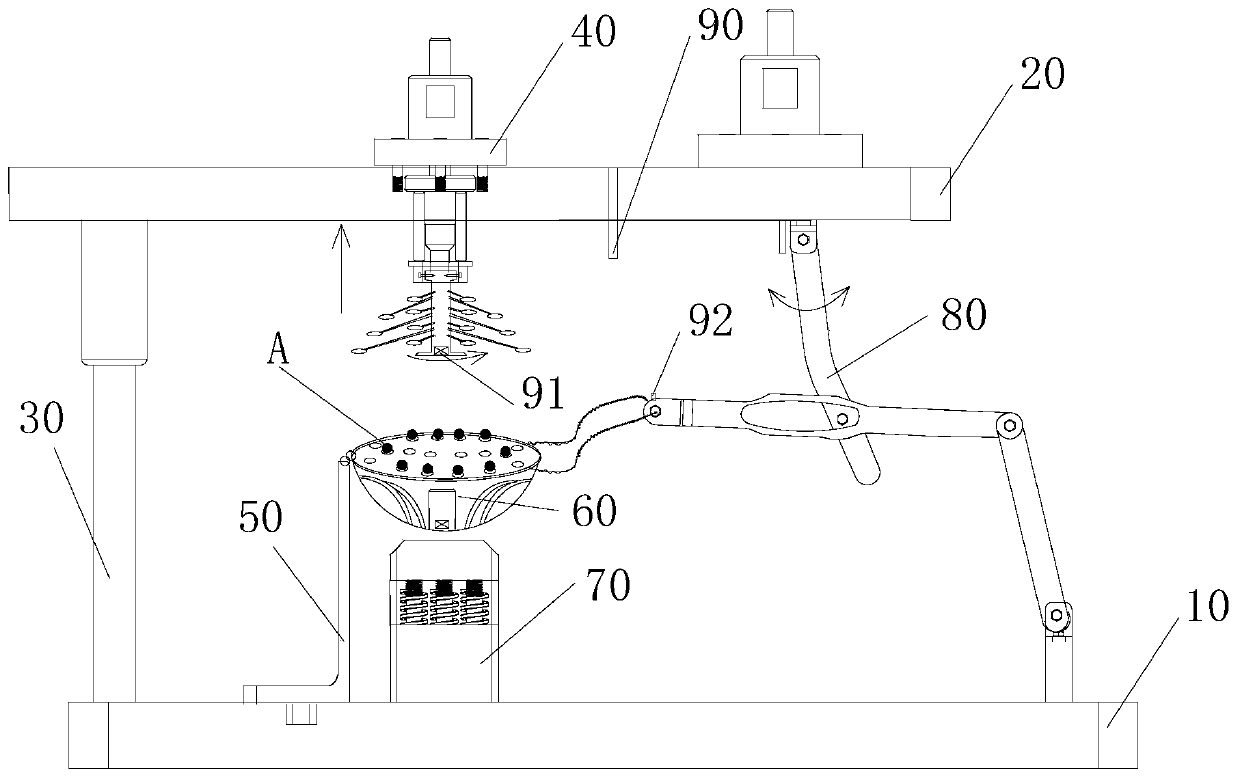

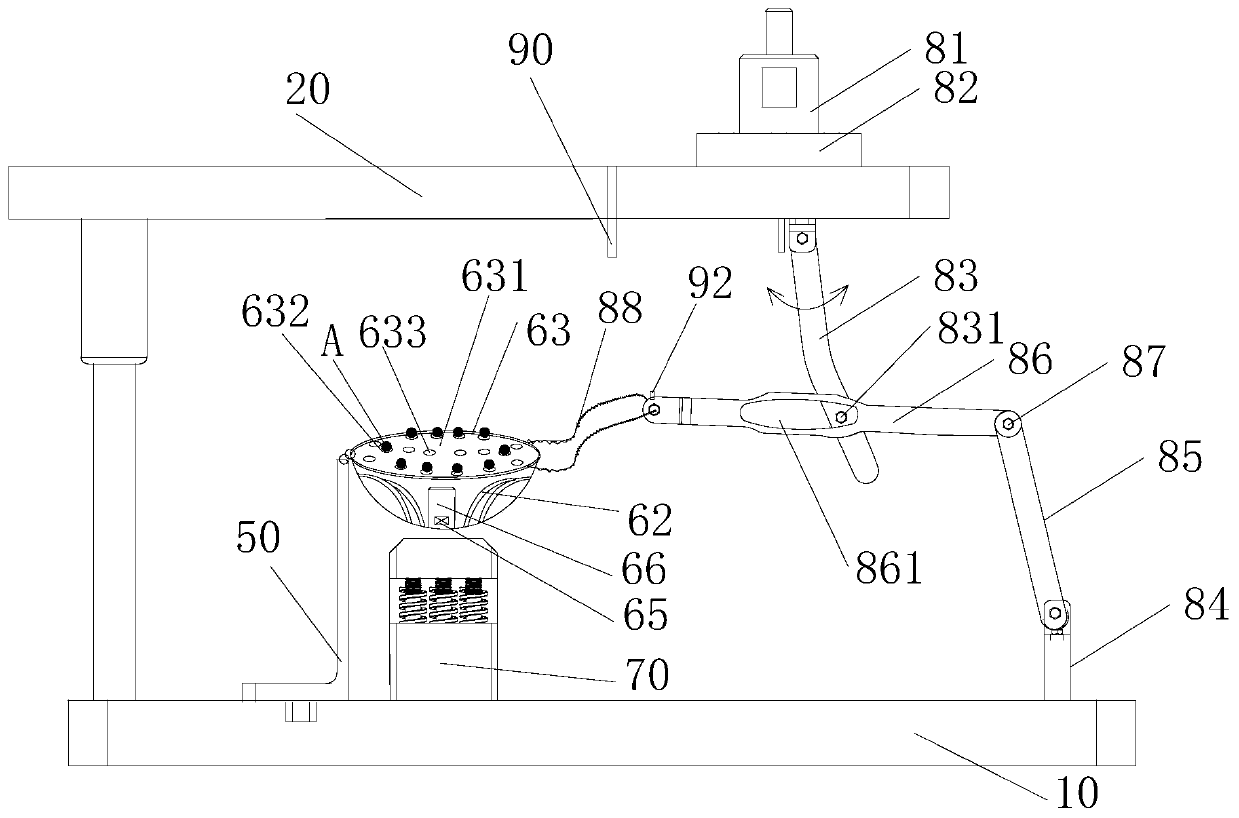

[0045] Embodiment one: see Figure 11 , Figure 12 A control system for blowing and self-unloading equipment for high-viscosity pharmaceutical capsules provided in Embodiment 1 of the present invention includes a controller 90, a capsule position detection device 91, and a signal trigger 92 (in addition, regarding high-viscosity pharmaceutical capsules. The mechanical structure of the unloading equipment still needs to refer to Figure 1-Figure 10 );

[0046] Wherein, the controller 90 includes a parameter preset module 901, a hydraulic cylinder control module 902, a first drive motor control module 903, a suction device control module 904, a second drive motor control module 905 and a blower control module 906; the controller 90 is fixed It is connected at the bottom position of the upper support base 20, and the controller 90 is installed between the workbench device 60 and the first link 83 in the structure of the trigger drive assembly 80; it should be noted that the con...

Embodiment 2

[0062] Embodiment two: see Figure 13 , Embodiment 2 of the present invention provides a control method for blowing and clearing self-unloading equipment for high-viscosity pharmaceutical capsules, using the control system for blowing and clearing self-unloading equipment for high-viscosity pharmaceutical capsules to implement control, and perform the following steps:

[0063] Step S100: After the controller 90 receives the start control instruction, it controls the hydraulic telescopic system 41 on the cleaning device structure to move downward through the hydraulic cylinder control module 902, and receives the capsule position detection information sent by the capsule position detection device 91 in real time; After the device 90 determines that the current capsule position distance in the real-time capsule position detection information is less than the preset distance, it uses the hydraulic cylinder control module 902 to control the hydraulic telescopic system 41 to stop mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com