Device and method capable of preparing spherical powder through high-energy plasma flame flow

A high-energy plasma and spherical powder technology, applied in the field of powder metallurgy, can solve the problems of low titanium powder efficiency, high powder price and high cost, and achieve the effects of improving preparation efficiency, high preparation efficiency and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

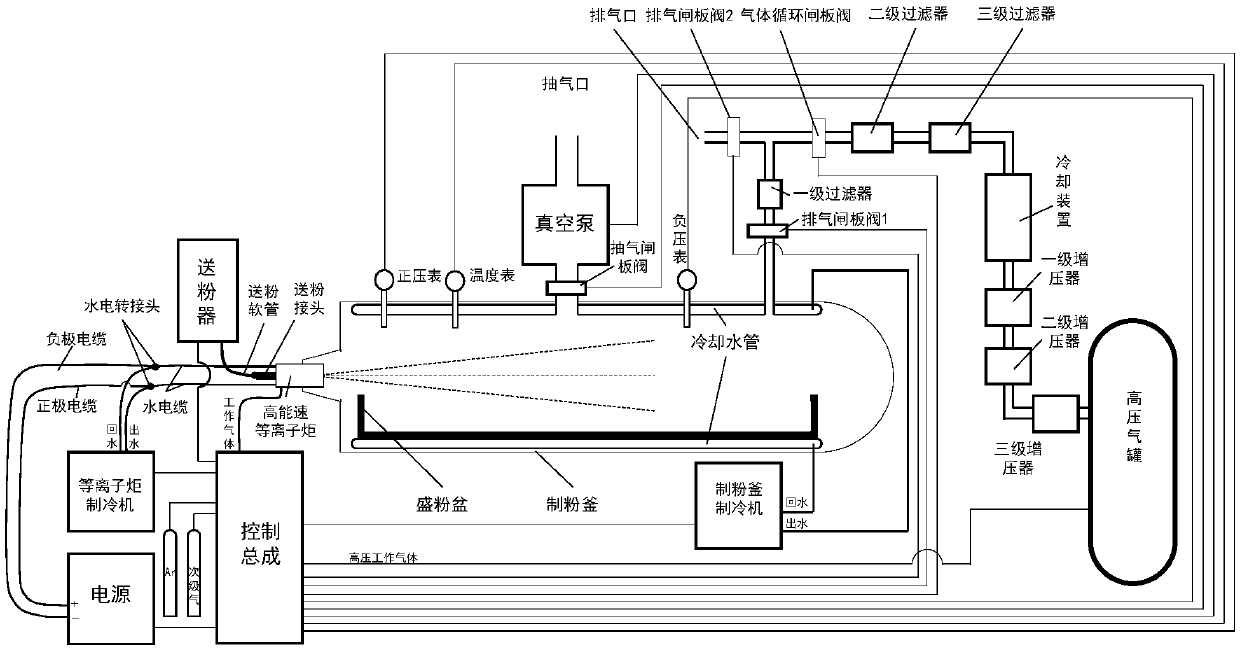

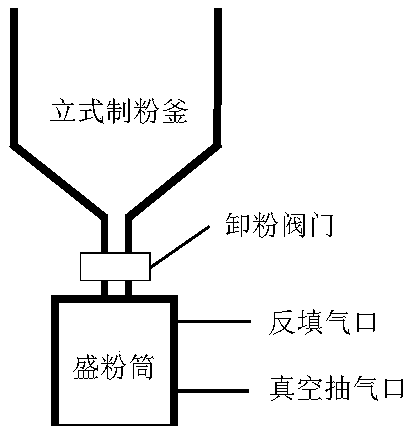

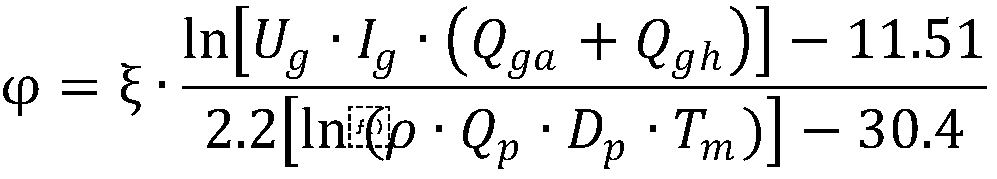

[0051] Such as figure 1 As shown, the present invention provides a device for preparing spherical powder with a high-energy plasma flame, including: a powder making kettle; hole; a powder feeder, which is connected to one end of the powder feeding pipe, and the other end of the powder feeding pipe is sent into the plasma torch along the axial direction of the plasma torch spray gun, and is used to transport raw material powder into the plasma torch spray gun.

[0052] In this embodiment, the powder-making kettle is a horizontal powder-making kettle, and a semi-cylindrical powder-holding basin is arranged horizontally inside it. The length of the powder-holding basin is consistent with the internal length of the powder-making kettle, and the height is 1 / 3 of the height of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com