Tool fault intelligent diagnosing system

A technology for intelligent diagnosis and failure, applied in manufacturing tools, wood processing equipment, circular saws, etc., can solve problems such as harsh noise, cuts, and affecting production efficiency, and achieve the effects of improving accuracy, easy implementation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is a further detailed description through specific implementations:

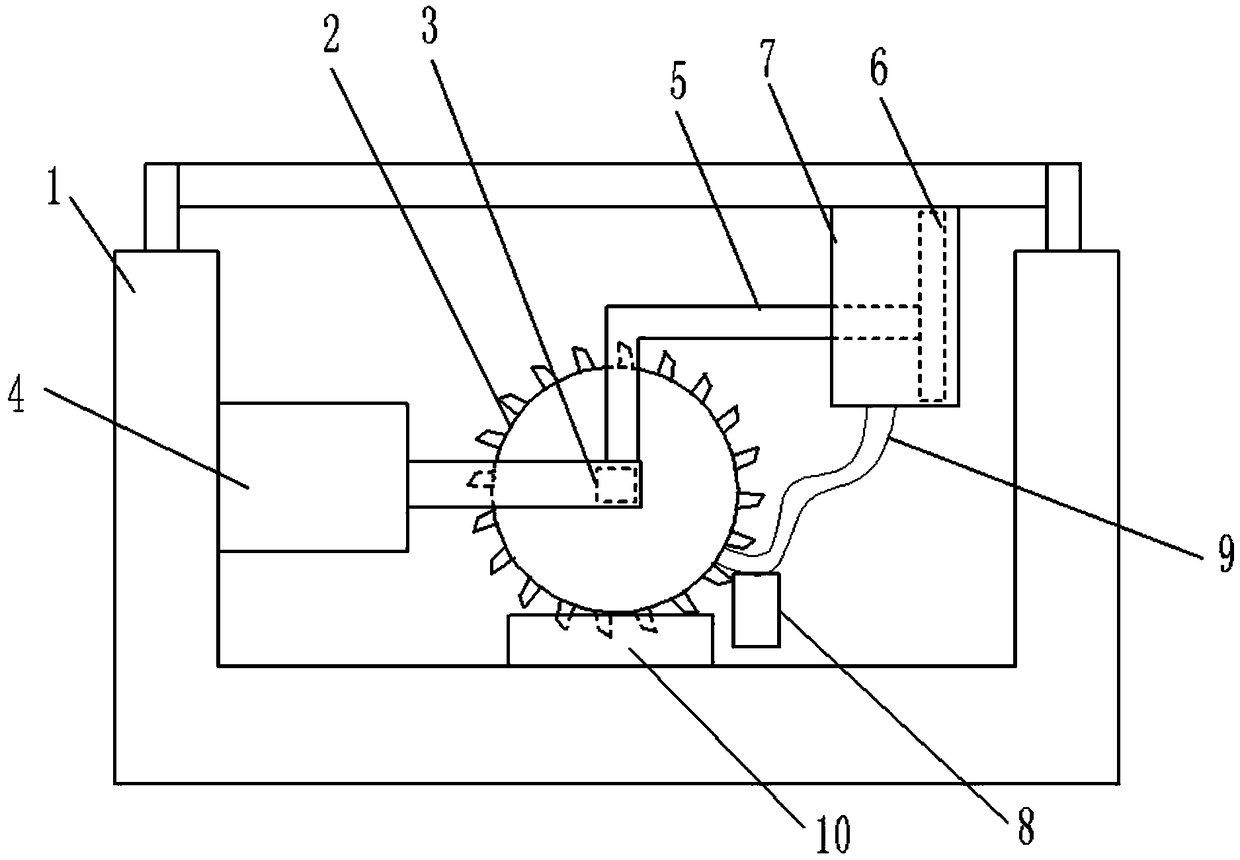

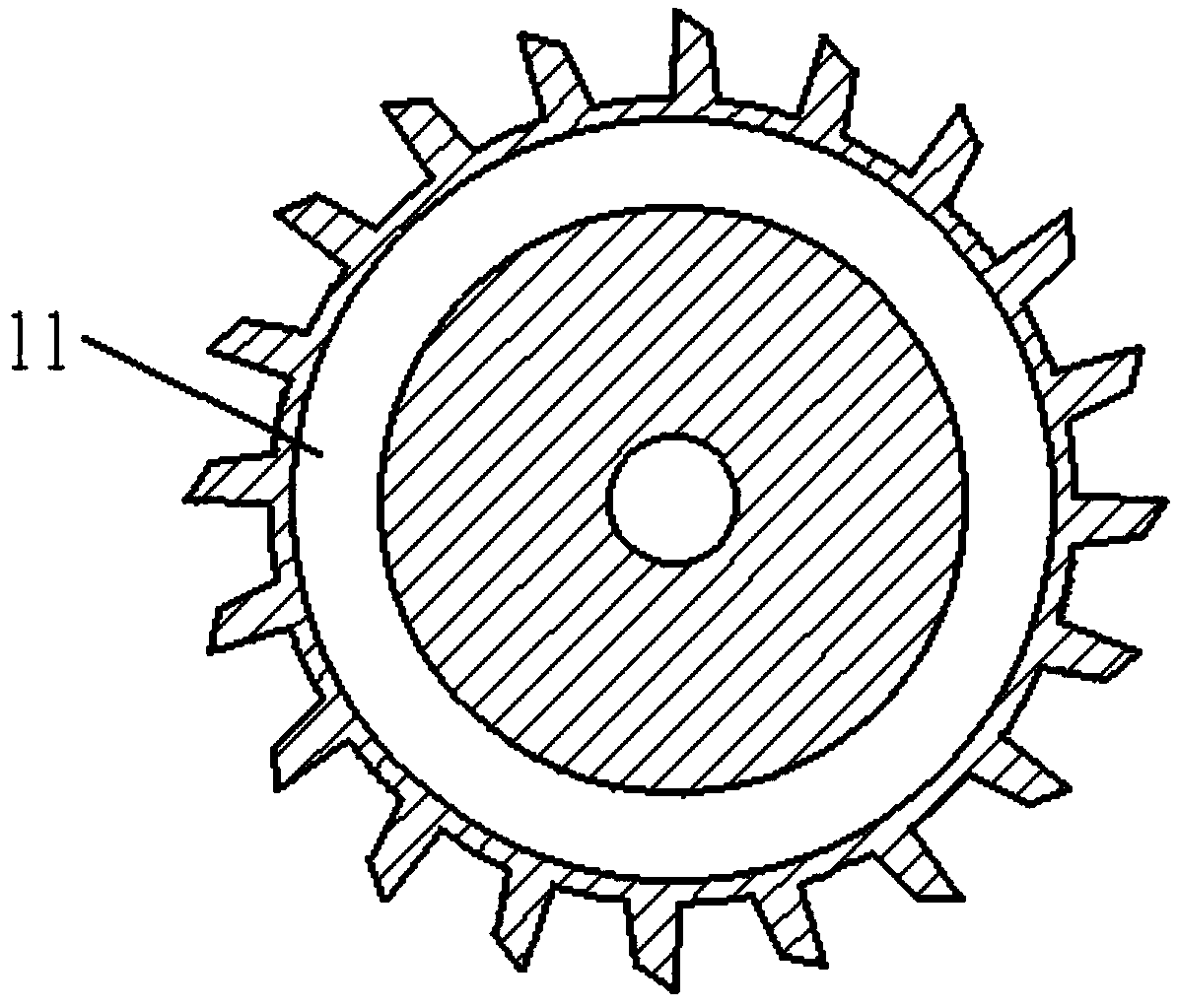

[0022] The reference signs in the drawings of the specification include: processing table 1, circular saw 2, connecting seat 3, cylinder 4, connecting rod 5, piston 6, air storage box 7, chip storage box 8, bellows 9, infrared receiver 10. Cavity 11.

[0023] The embodiment is basically as attached figure 1 Shown: The tool fault intelligent diagnosis system includes the processing table 1, the circular saw 2 and the power unit. The power unit includes the cylinder 4, the connecting seat 3 and the connecting column (not shown in the figure). The connecting seat 3 is welded to the cylinder 4 On the side of the piston rod, the end face of the connecting seat 3 is flat. The center of the circular saw 2 is provided with a through hole. The through hole is in interference fit with the connecting column. The connecting seat 3 and the corresponding position of the connecting column are provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com