Liquid discharging apparatus and circuit substrate

A circuit substrate and liquid technology, applied in printing devices, printed circuits, printed circuits, etc., can solve the problems of undisclosed circuit substrates, cooling components, etc., to achieve efficient cooling components, efficient cooling, reduction of ejection characteristics and product life. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0052] 1.1 Outline of liquid ejection device

[0053] A printing device as an example of the liquid ejecting device of the first embodiment is an inkjet printer that ejects ink based on image data supplied from an external host computer to form groups of ink dots on a printing medium such as paper, thereby An image (including characters, graphics, etc.) corresponding to the image data is printed.

[0054] In addition, as the liquid ejection device, in addition to printing devices such as printers, for example, a colorant ejection device used in the manufacture of color filters such as liquid crystal displays, organic EL displays, FED (field induced Electrode material discharge devices used in electrode formation such as light-emitting displays), bioorganic substance discharge devices used in biochip production, three-dimensional modeling devices (so-called 3D printers), printing and dyeing devices, etc.

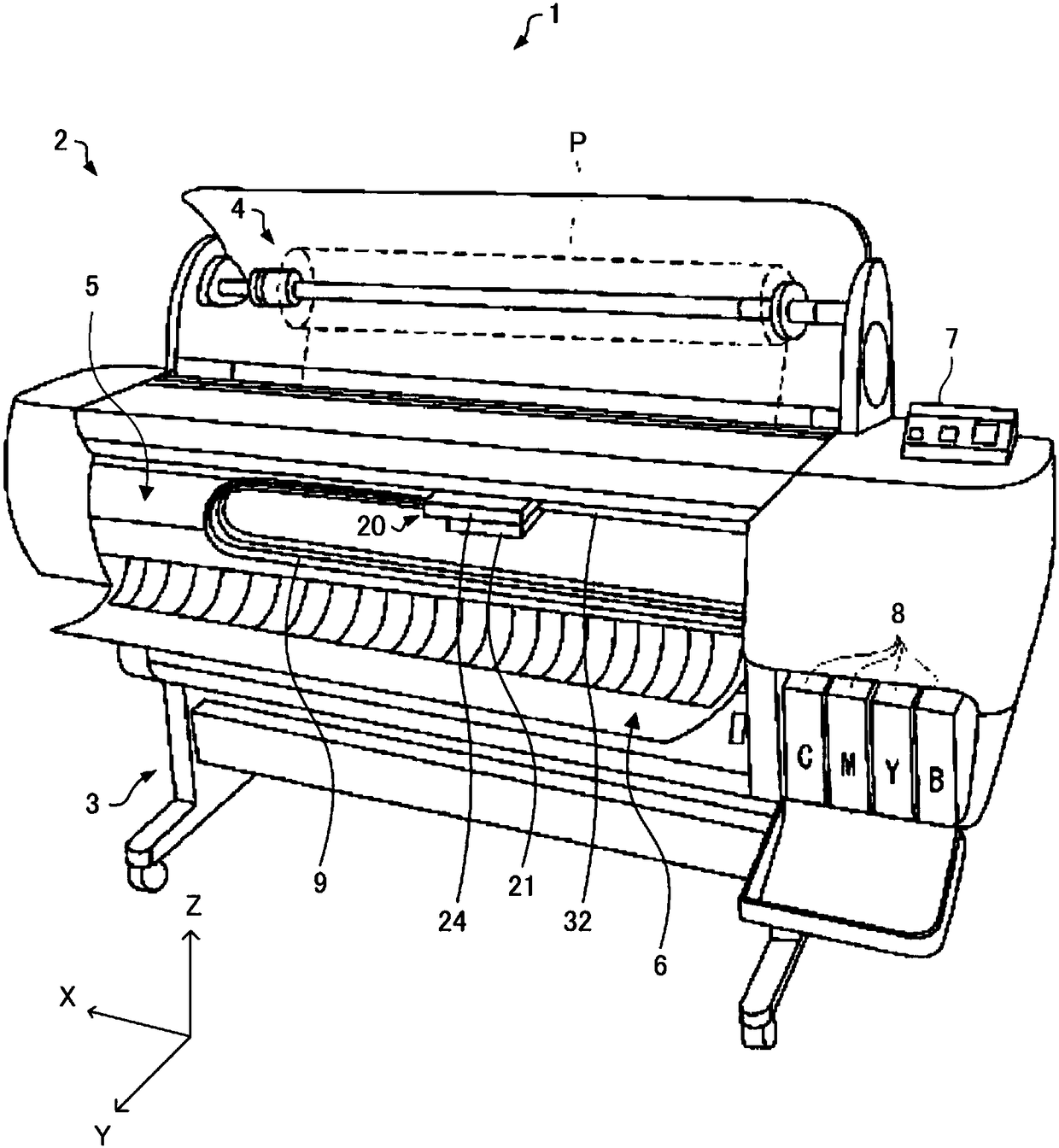

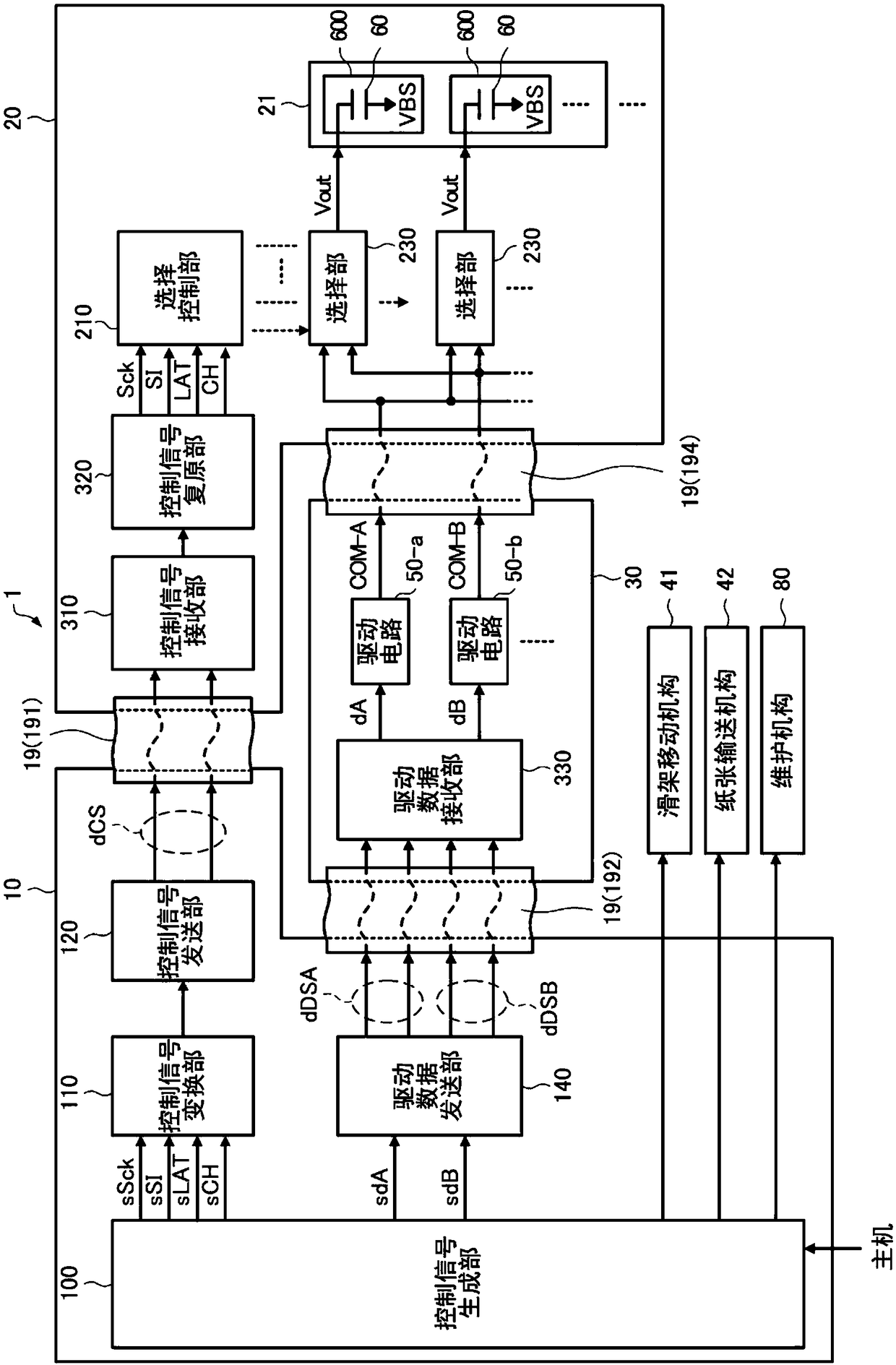

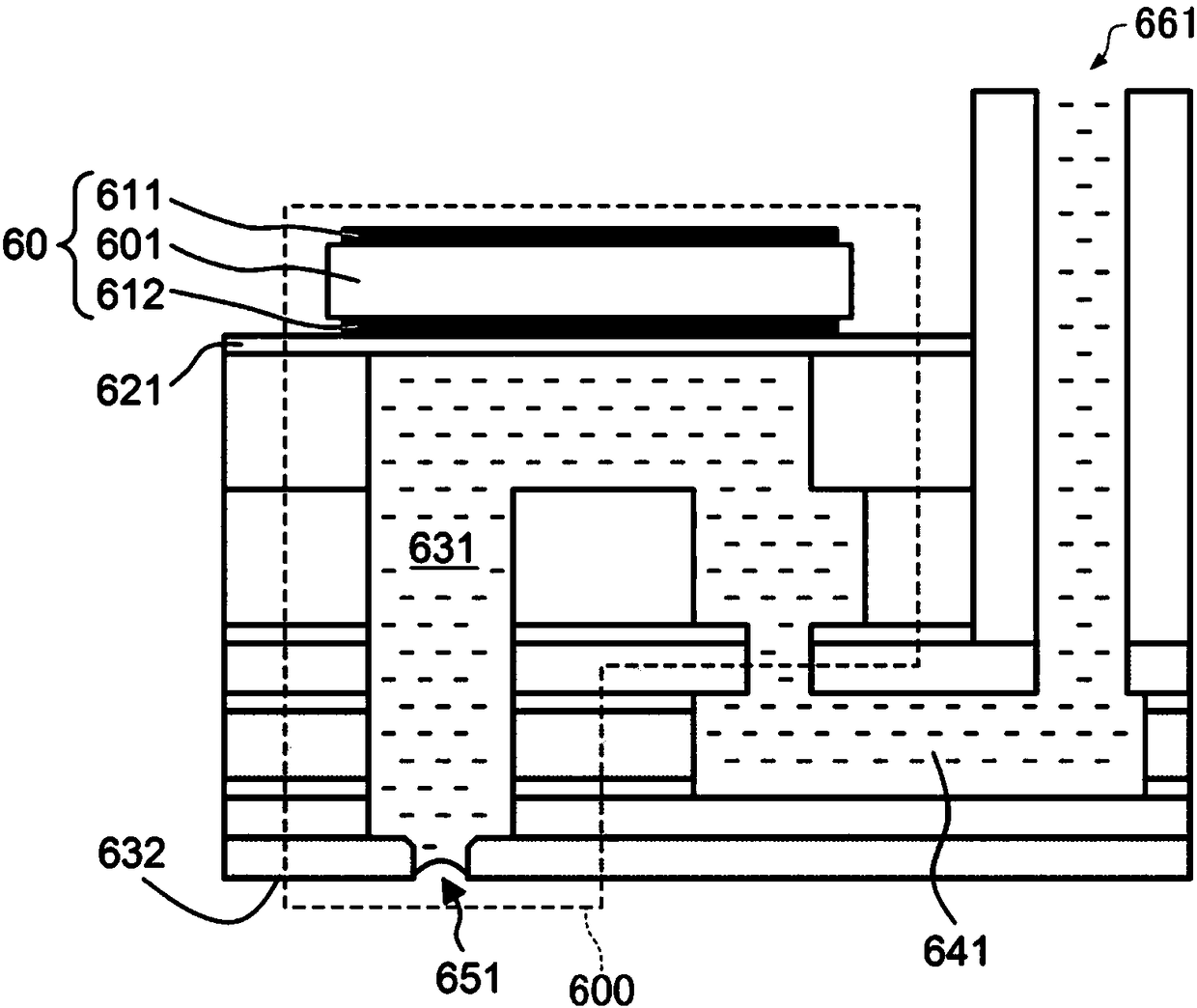

[0055] figure 1 is a schematic diagram of the appearance of the liquid...

no. 2 approach

[0260] The liquid ejection device 1 according to the second embodiment has the same configuration as that of the liquid ejection device 1 according to the first embodiment, except that the layout of the drive signal generation unit 460 of the drive circuit board 420 included in the drive unit 30 is different. . Hereinafter, the content overlapping with the first embodiment will be omitted or simplified, and the content different from the first embodiment will be mainly described.

[0261] Figure 18 It is a schematic diagram showing the layout of the drive circuit board 420 in the second embodiment. also, Figure 18 The direction x, the direction y, and the direction z which are orthogonal to each other are shown and demonstrated in .

[0262] The liquid ejection device 1 according to the second embodiment has the same configuration as that of the liquid ejection device 1 according to the first embodiment, and its illustration and description are omitted ( figure 1 ). In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com