Styrene polymer and preparation method thereof

A technology of styrene polymer and mixed liquid, applied in coating and other directions, can solve the problems of poor ink resolution and poor alkali solubility, and achieve the effect of fast sensitivity and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

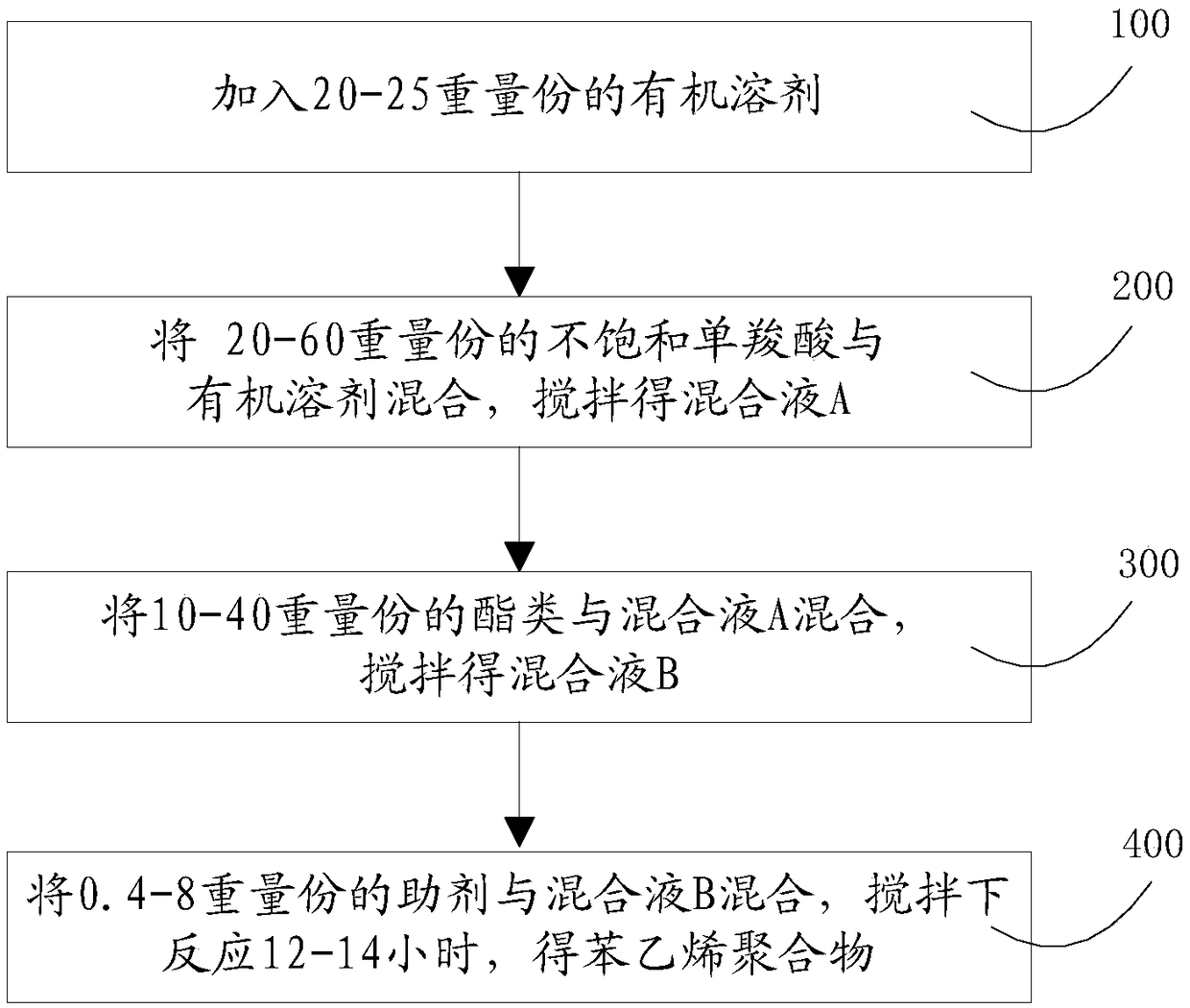

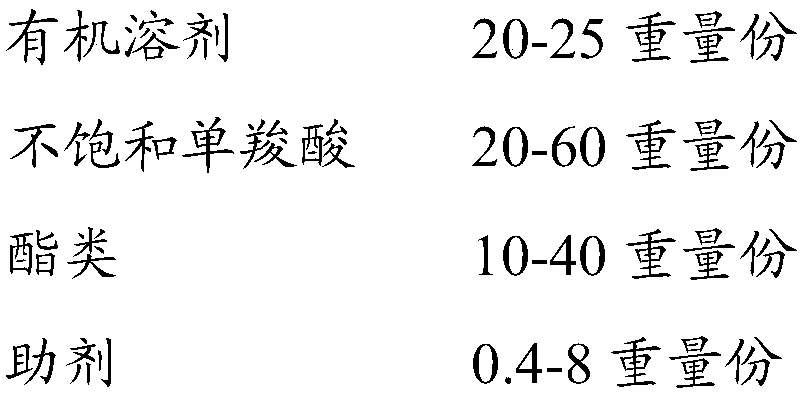

[0034] The present invention also provides a preparation method of styrene polymer, according to which the above-mentioned styrene polymer can be prepared, such as figure 1 shown, including the following steps:

[0035] Step 100, adding 20-25 parts by weight of an organic solvent;

[0036] Step 200, mixing 20-60 parts by weight of unsaturated monocarboxylic acid with an organic solvent, and stirring to obtain a mixed solution A;

[0037] Step 300, mixing 10-40 parts by weight of esters with mixed solution A, and stirring to obtain mixed solution B;

[0038] In step 400, 0.4-8 parts by weight of additives are mixed with the mixed solution B, and reacted for 12-14 hours under stirring to obtain a styrene polymer.

[0039] Each of the above steps is carried out at a reaction temperature of 95-110°C.

[0040] Specifically, the organic solvent includes one or more of PGMEA (Propylene glycol monomethyl ether acetate), PM (Proprylene glycol monomethyl ether, propylene glycol methy...

Embodiment 1

[0047] Add 20 parts by weight of propylene glycol methyl ether acetate, and heat the solution under stirring, and the heating temperature is 95° C.;

[0048] Add 35 parts by weight of acrylic acid and propylene glycol methyl ether acetate to mix, and stir until dissolved under heating to obtain a mixed solution A;

[0049] Add 40 parts by weight of methyl methacrylate to mix with mixed solution A, and stir under heating to obtain mixed solution B;

[0050] Add 1 part by weight of solubilizer, 0.1 part by weight of desulfurizer, 2 parts by weight of initiator and 1 part by weight of molecular weight regulator and mix with mixed liquid B, stir and react for 12-14 hours under heating to obtain benzene vinyl polymer.

[0051] After testing, the styrene polymer prepared in this example has quick-drying properties, it can be quickly cured when coated on a circuit board, and has a certain alkali solubility after curing, and the styrene polymer prepared in this example It has high r...

Embodiment 2

[0053] Add 20 parts by weight of propylene glycol methyl ether acetate, and heat the solution under stirring, and the heating temperature is 95° C.;

[0054] Add 20 parts by weight of acrylic acid, 15 parts by weight of methacrylic acid and propylene glycol methyl ether acetate to mix, and stir until dissolved under heating to obtain a mixed solution A;

[0055] Add 40 parts by weight of methyl methacrylate to mix with mixed solution A, and stir under heating to obtain mixed solution B;

[0056] Add 1 part by weight of solubilizer, 0.1 part by weight of desulfurizer, 2 parts by weight of initiator and 1 part by weight of molecular weight regulator and mix with mixed liquid B, stir and react for 12-14 hours under heating to obtain benzene vinyl polymer.

[0057] After testing, the styrene polymer prepared in this example has quick-drying characteristics, and it can be quickly cured when coated on a circuit board, and has a certain alkali solubility after curing, and the resolu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com