Method of using high-concentration organic wastewater of milk factories to cultivate green alga A. dimorphus to prepare lipids and polysaccharides

An organic wastewater, high-concentration technology, applied in the field of high-value chemicals lipids and polysaccharides, to eliminate interference and simplify culture conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below through specific embodiments and accompanying drawings. The embodiments of the present invention are for better understanding of the present invention by those skilled in the art, and do not limit the present invention in any way.

[0039] The present invention utilizes the high-concentration organic waste water of milk factory to cultivate the green algae A.dimorphus to prepare the method for lipid and polysaccharide, comprises the following steps:

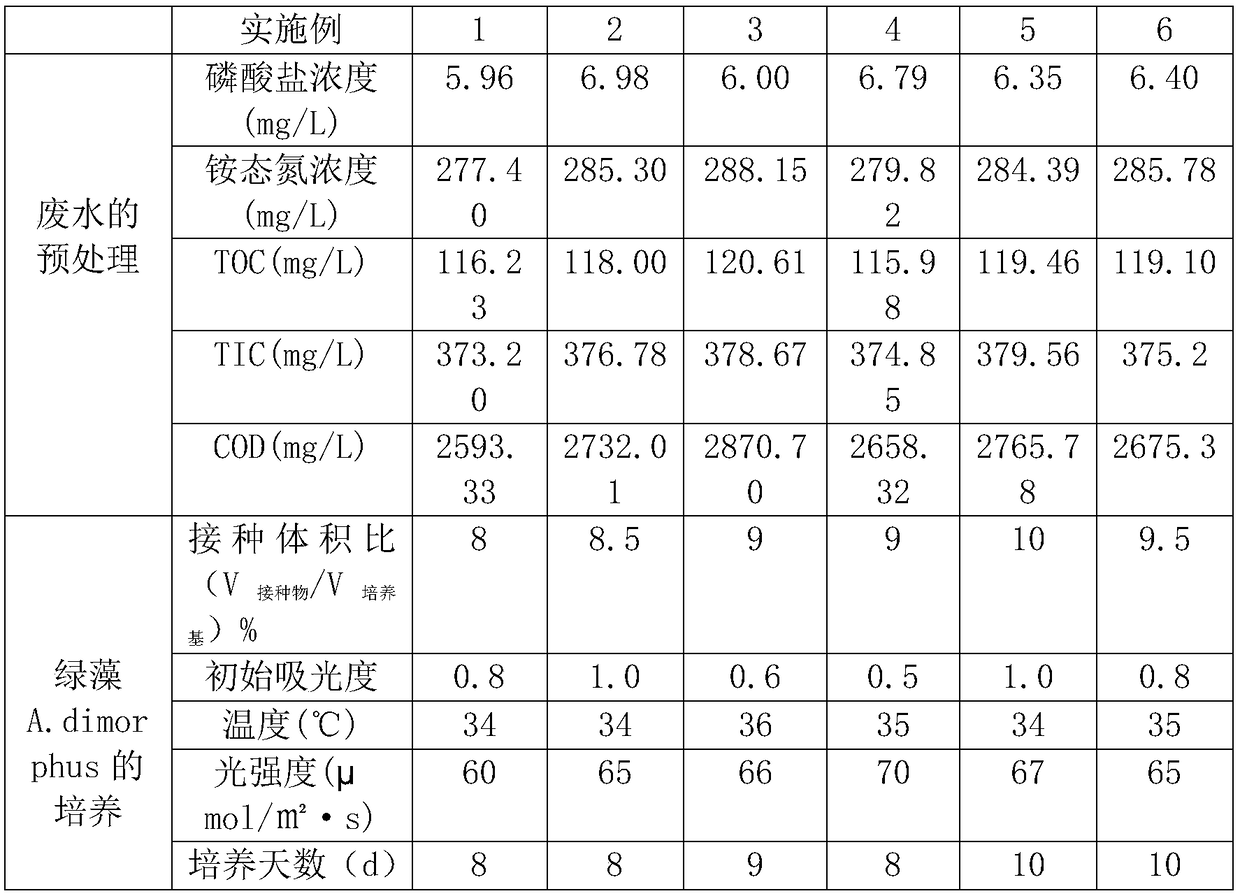

[0040] 1) Wastewater pretreatment: Milk wastewater (DWW) is filtered and stored in a refrigerator at 4°C without any dilution or sterilization;

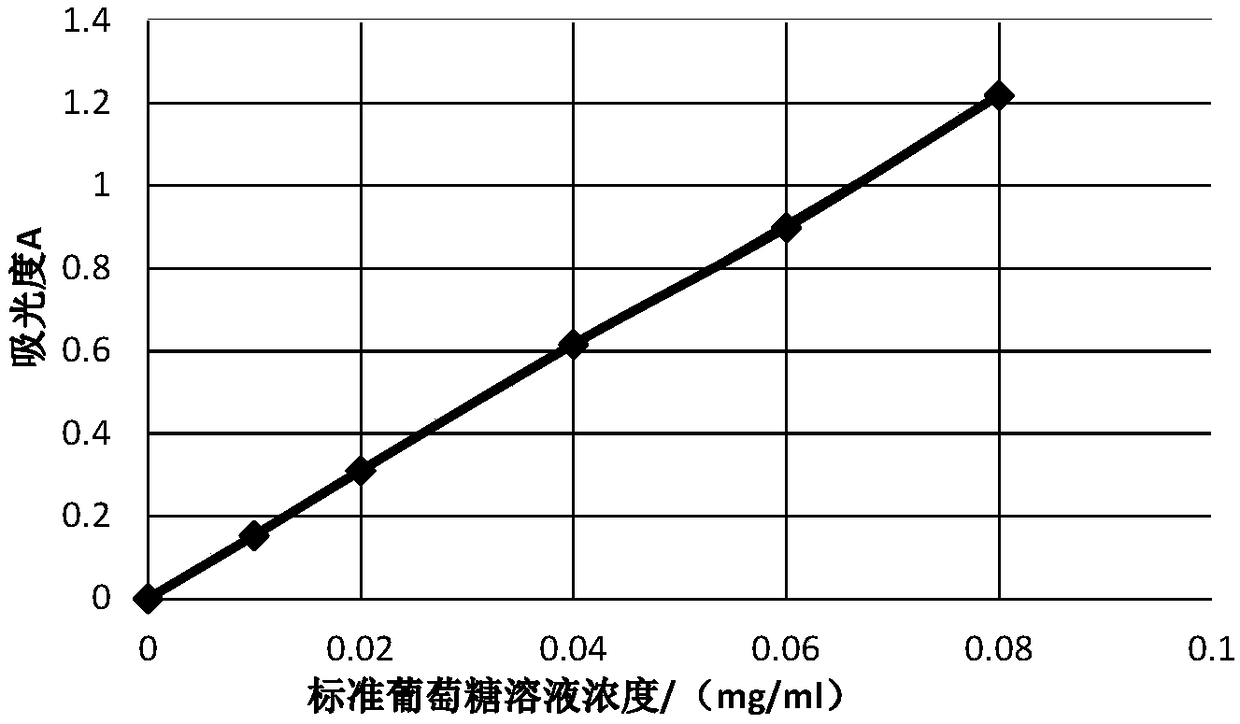

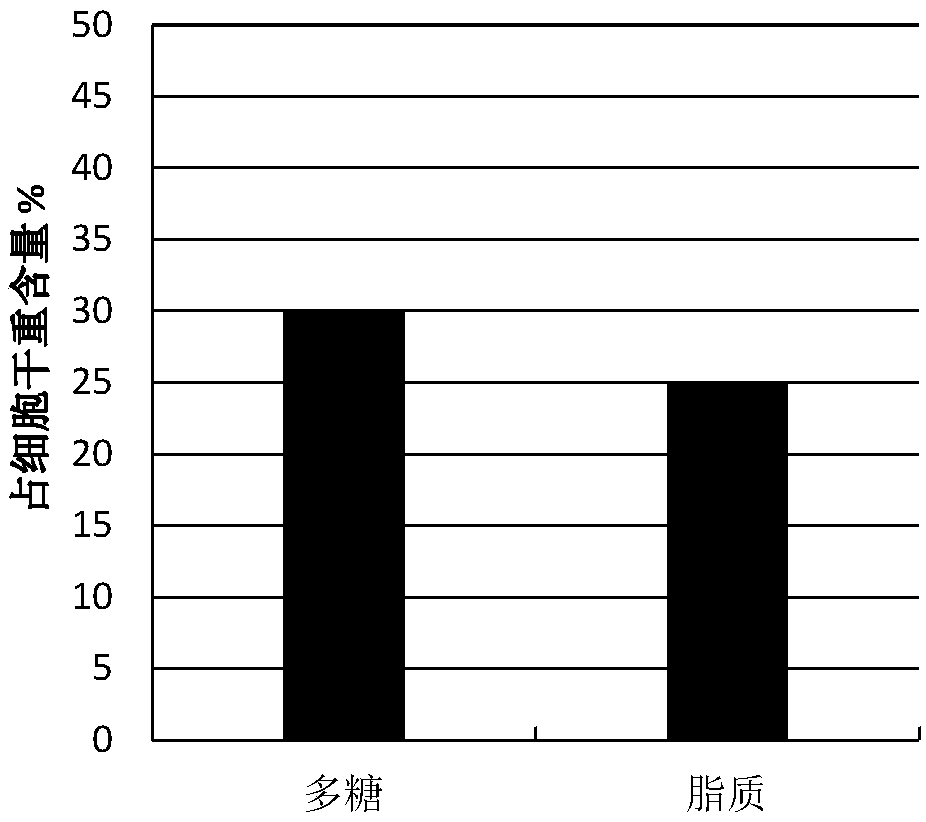

[0041] Among them, phosphate in milk wastewater (DWW) is 5.96±0.04mg / L, ammonia nitrogen is 277.40±10.75mg / L, chemical oxygen demand (COD) is 2593.33±277.37mg / L, total organic carbon (TOC) is 116.23±4.3, the total Inorganic carbon (TIC) 373.20±5.47mg / L; 2) Cultivation of green algae A.dimorphus: Add 500ml of unsterilized and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com