Method for calibrating Tau curve of hollow coil sensor

A technology of hollow coil and calibration method, which is applied in the direction of instruments, measuring devices, and measuring electrical variables, etc., which can solve the problems of inapplicability to solve the transfer function of the receiving coil, complicated process, and low accuracy of the numerical solution of the induced voltage curve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0104] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

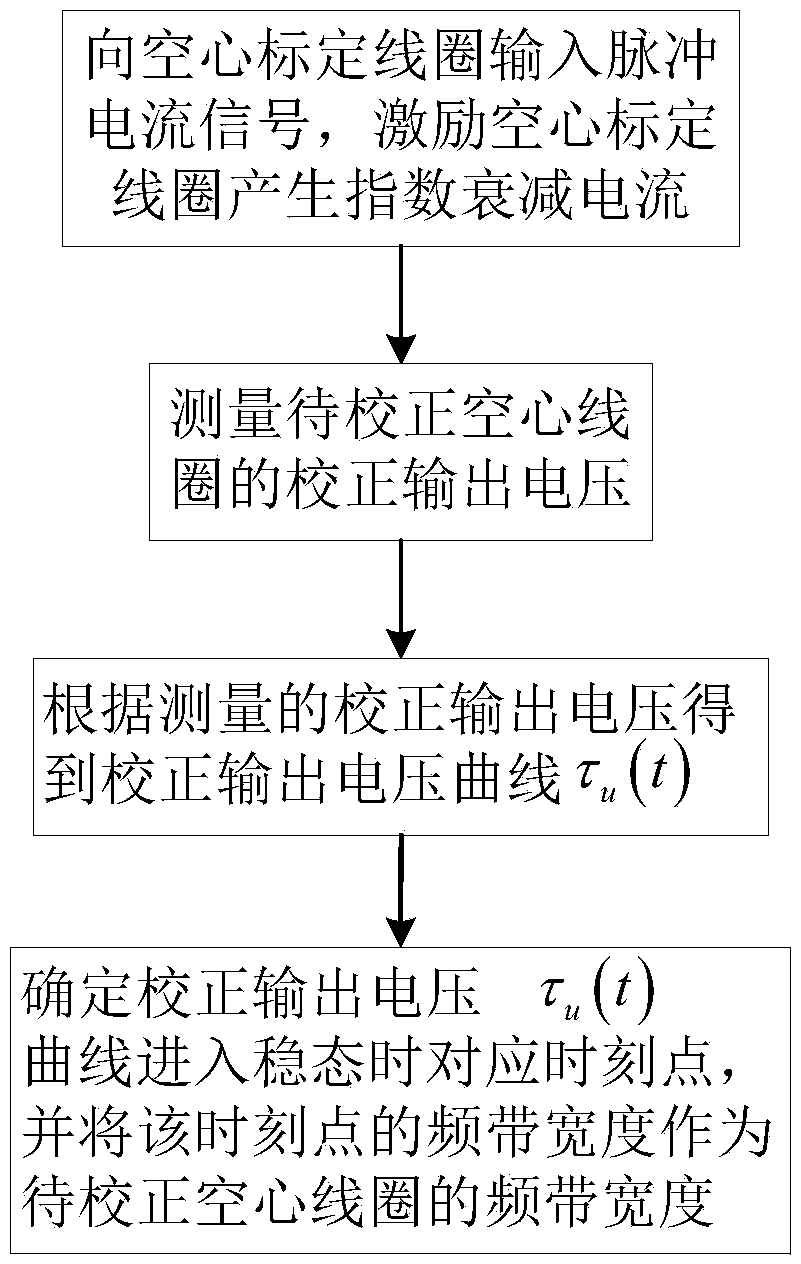

[0105] A method for calibrating a τ curve of an air-core coil sensor, comprising:

[0106] Steps for building a calibration system;

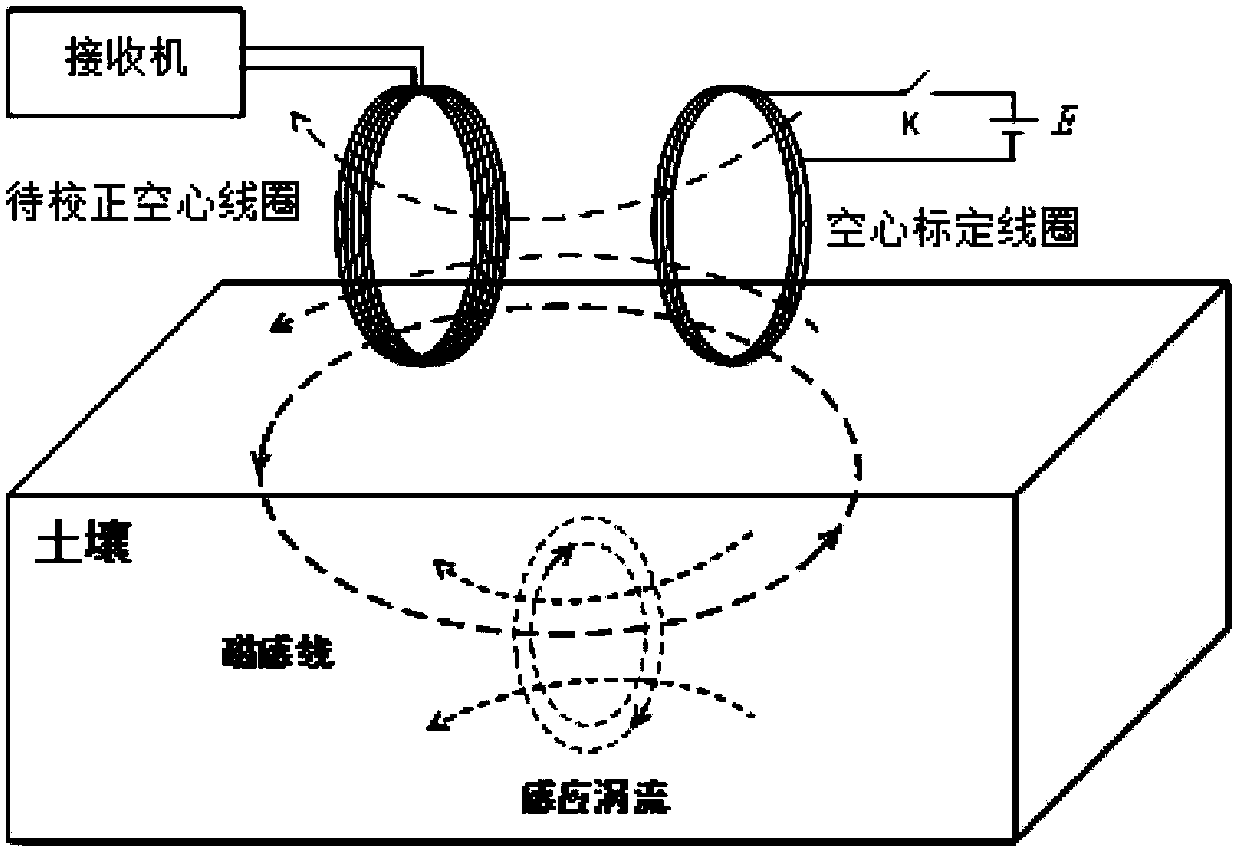

[0107] combine figure 2 It can be seen that the calibration system includes an air-core calibration coil and two air-core coils to be calibrated, and the two air-core coils to be calibrated are respectively: the first air-core coil to be calibrated and the second air-core coil to be calibrated. The hollow calibration coil is connected to both ends of the DC power supply, and a control switch is connected to the connection line between the DC power supply and the hollow calibration coil; the two ends of the hollow coil to be corrected are connected to the receiver.

[0108] For small air-core coils to be calibrated, the air-core calibration coil and the air-core coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com