Irregular box type mixer

A mixer and special-shaped technology, applied in the direction of fluid mixers, mixers, chemical instruments and methods, etc., can solve the problems of inconvenient installation and disassembly, large pressure loss, high pressure loss, etc., and achieve simple structure and low flow field pressure difference , No flow dead angle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

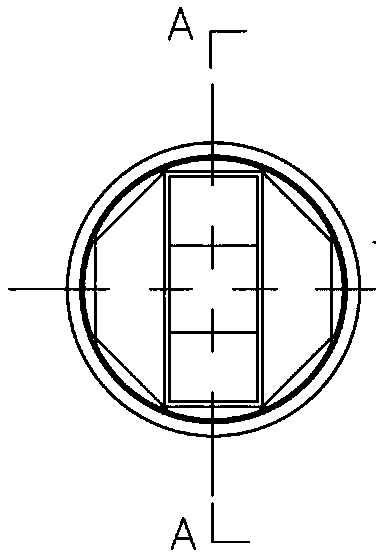

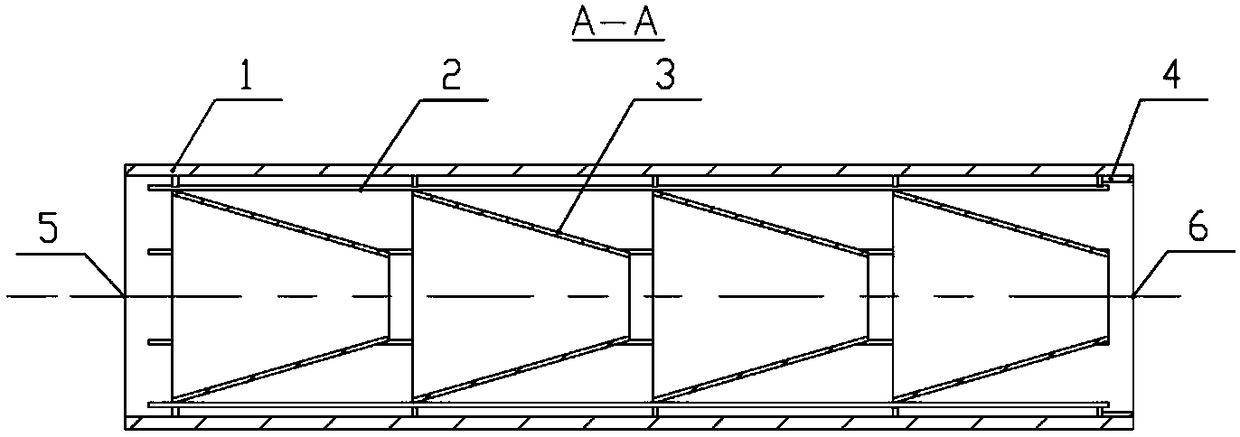

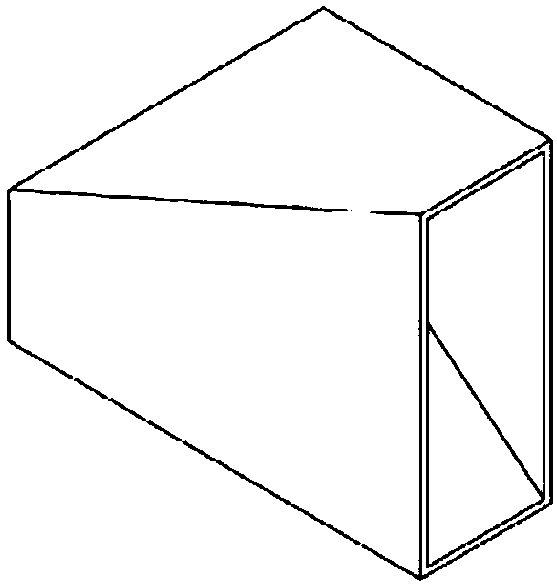

[0024] The special-shaped box mixer specifically includes a pipeline 1, an inlet pipe 5 is provided on one side of the pipeline 1; an outlet pipe 6 is provided on the other side of the pipeline 1 away from the inlet 5; a plurality of pipes are evenly arranged in the pipeline 1 The special-shaped box 3, the said special-shaped box 3 is a prism-like shape composed of two mutually perpendicular rectangles at the entrance and exit, and the interior of the structure is hollow; the outer wall of the said special-shaped box 3 is provided with a bracket 2, and the special-shaped box 3 passes through the bracket 2 It is fixedly connected with the inner wall of the pipeline 1; the outlet end of the pipeline 1 is provided with a fixed snap ring 4) and the position of the bracket 2 is fixed through the fixed snap ring 4.

Embodiment 2

[0026] The quantity of special-shaped boxes 2 is 5-8 and is all arranged in the pipeline 1, the spacing between the special-shaped boxes 3 is equal, and other structures are the same as in embodiment 1.

[0027] The present invention uses special-shaped box 3 to mix the fluid. When the fluid flows through the first special-shaped box 3, it is divided into two layers. One layer flows along the outside of the special-shaped box 3. Through the diversion of the shell of the special-shaped box 3, the pipeline 1. The central fluid flows outward; the other layer enters the special-shaped box 3 and mixes in the box; part of the fluid flowing out of the first special-shaped box 3 will enter the second special-shaped box 3 for mixing, and the other part will flow along the second special-shaped box 3. The outer sides of the two special-shaped boxes 3 flow. The outlets and inlets corresponding to adjacent special-shaped boxes 3 are perpendicular to each other (as Figure 7 ), so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com