Sandy soil recycling device of casting mold

A technology for casting molds and sand, which is used in manufacturing tools, casting equipment, and machinery for cleaning/processing of casting materials, etc., can solve the problems of occupying space, idle old sand, increasing production investment costs, etc., to reduce the cost of production. The effect of production investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose and technical solution of the present invention more clear, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

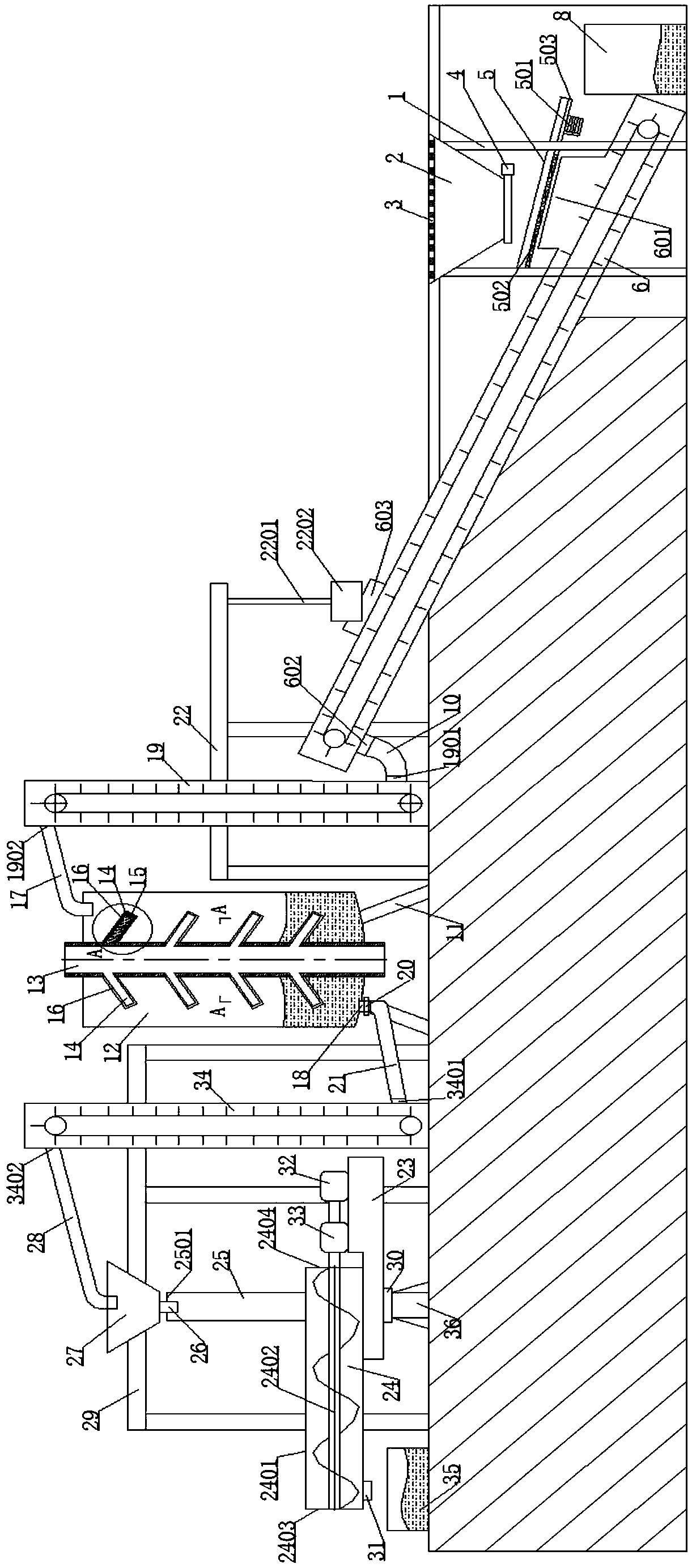

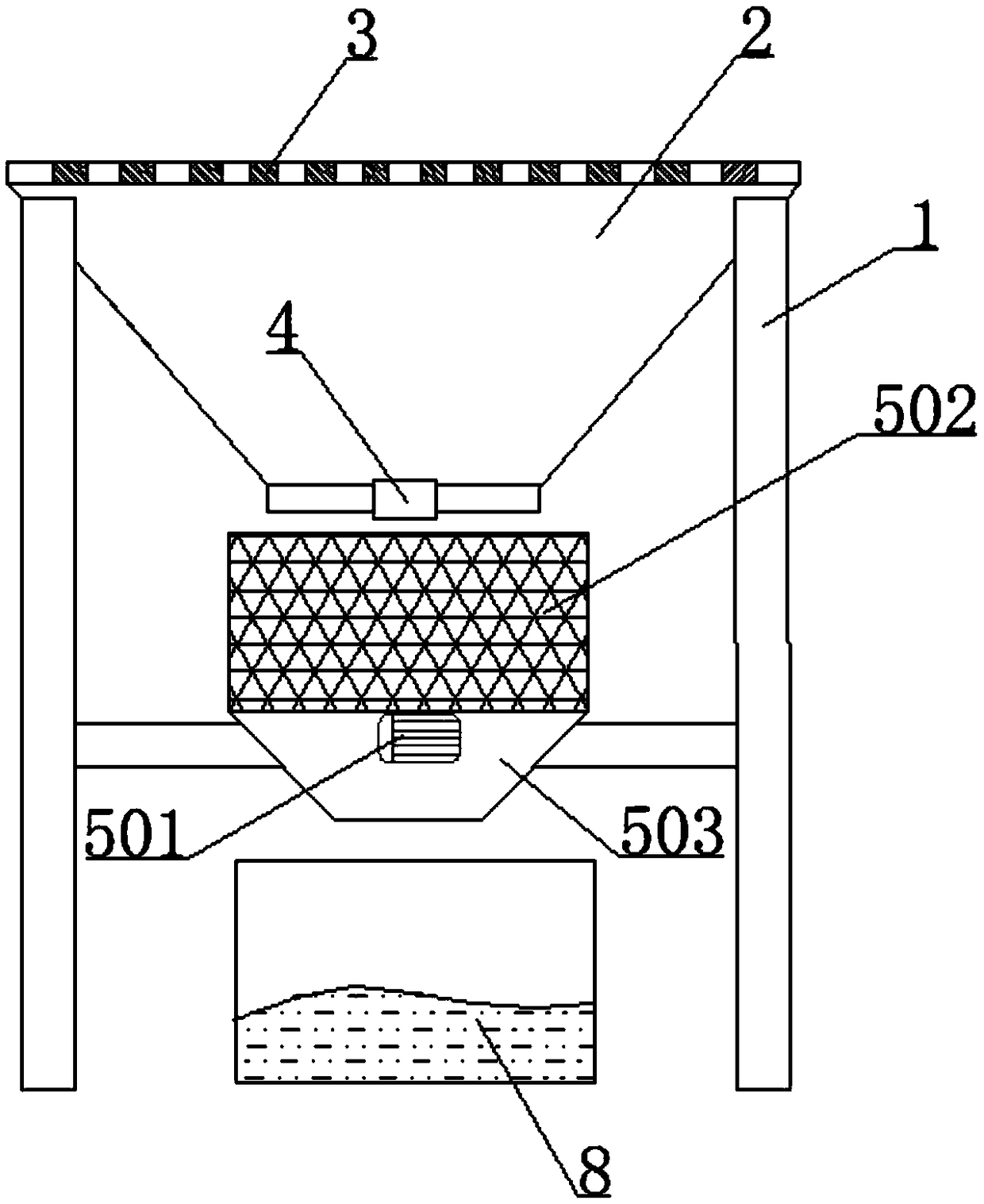

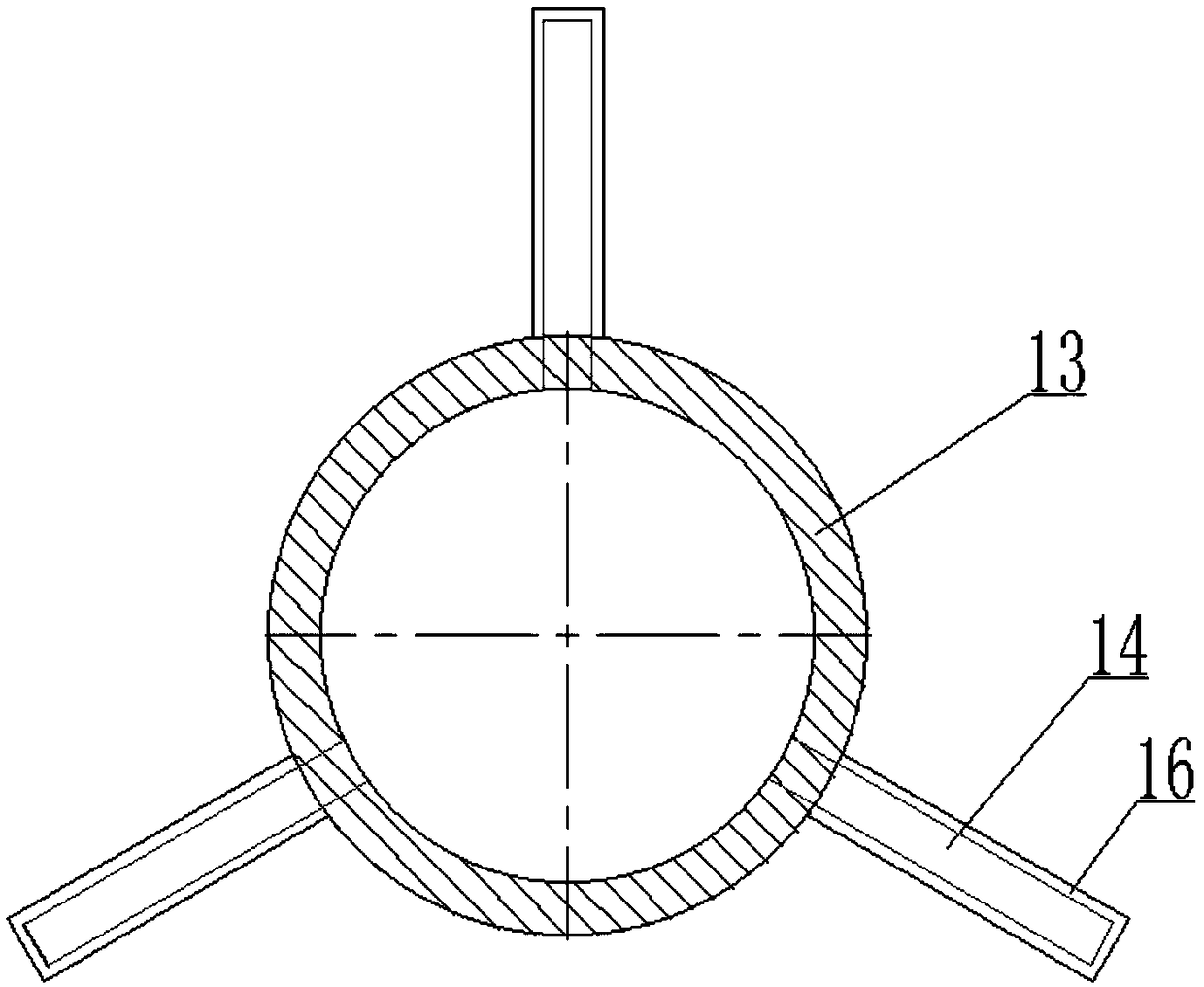

[0021] Such as figure 1 As shown, the present invention provides a casting mold sand recycling device, which includes a screening and impurity removal device, a cooling device and a sand delivery device. In this embodiment, the ground is used as a reference, wherein the screening and impurity removal device It is located below the ground, and the cooling device and the sand sending device are located above the ground. The screening and impurity removal device includes a first support frame 1, the top of the first support frame 1 is fixedly equipped with a hopper 2 with an opening facing upwards, the upper end of the hopper 2 is provided with a sieve plate 3, and the upper surface of the sieve plate 3 is connected to the upper surface of the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com