Hot melting hopper

A hot-melting and hopper technology, which is used in the transportation of passenger cars, tank cars, railway car body parts, etc., can solve the problems of slow hot-melting process, slow hot-melting speed, and inability to enter and exit materials at the same time, and achieve high energy utilization. The effect of fast melting speed and accelerating heat melting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

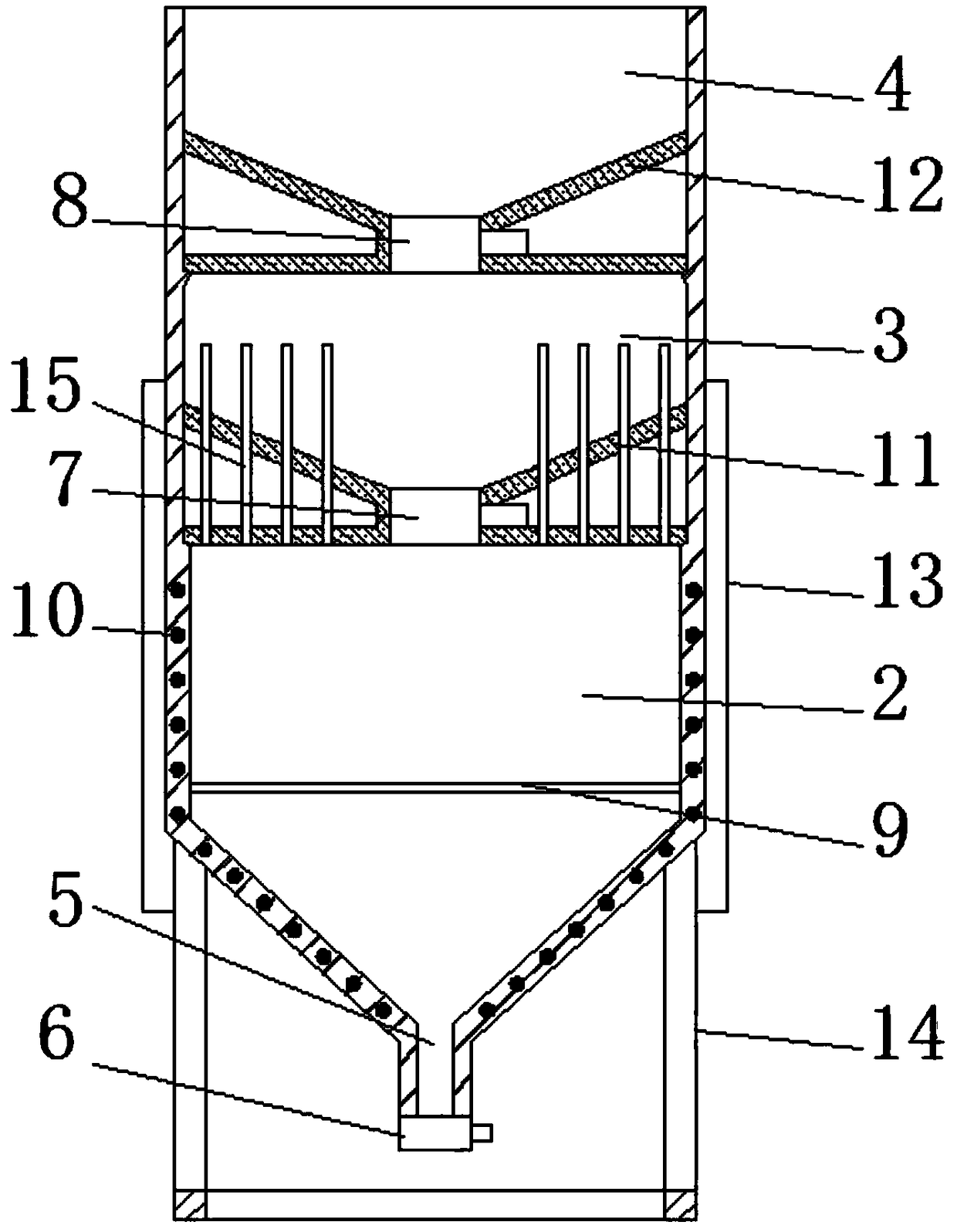

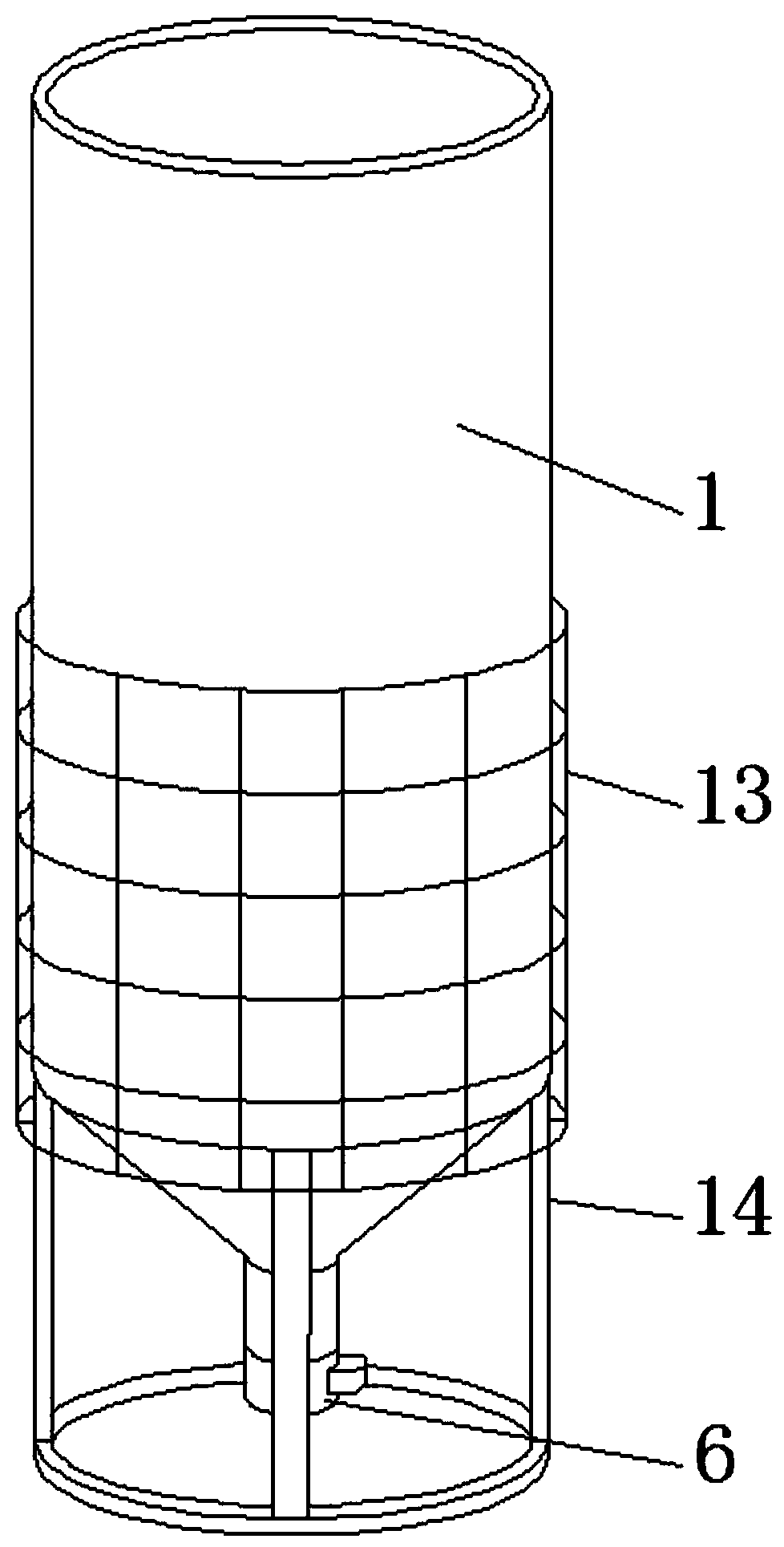

[0024] Refer to Figure 1~2 As shown, a hot melt hopper of the present invention includes a hopper body 1. The hopper body 1 is provided with a hot melt cavity 2, a buffer cavity 3, and a feed cavity 4 from bottom to top. One of the hot melt cavity 2 and the buffer cavity 3 There is a conducting part 15 for passing gas between the hot melt chamber 2 and a discharging port 5 is provided. The discharging port 5 is connected with an external liquid feeding pipe. The discharging port 5 is provided with a device for controlling the opening and closing of the discharging port 5 The first electric control valve 6, the hot melt chamber 2 and the buffer chamber 3 are provided with a second electronic control valve 7 for controlling the opening and closing of the material flow between the two, and the buffer chamber 3 and the feed chamber 4 are provided with A third electric control valve 8 that controls the opening and closing of the material flow between the two is provided with a heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com