Spinning oiling device and control method

A spinning and suction device technology, applied in the field of spinning oiling device and control, can solve the problems of disturbing fiber forming stability, fluctuation of tow spinning process tension, failure of normal production, etc. The effect of improving the nonuniformity of breaking strength and improving the breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

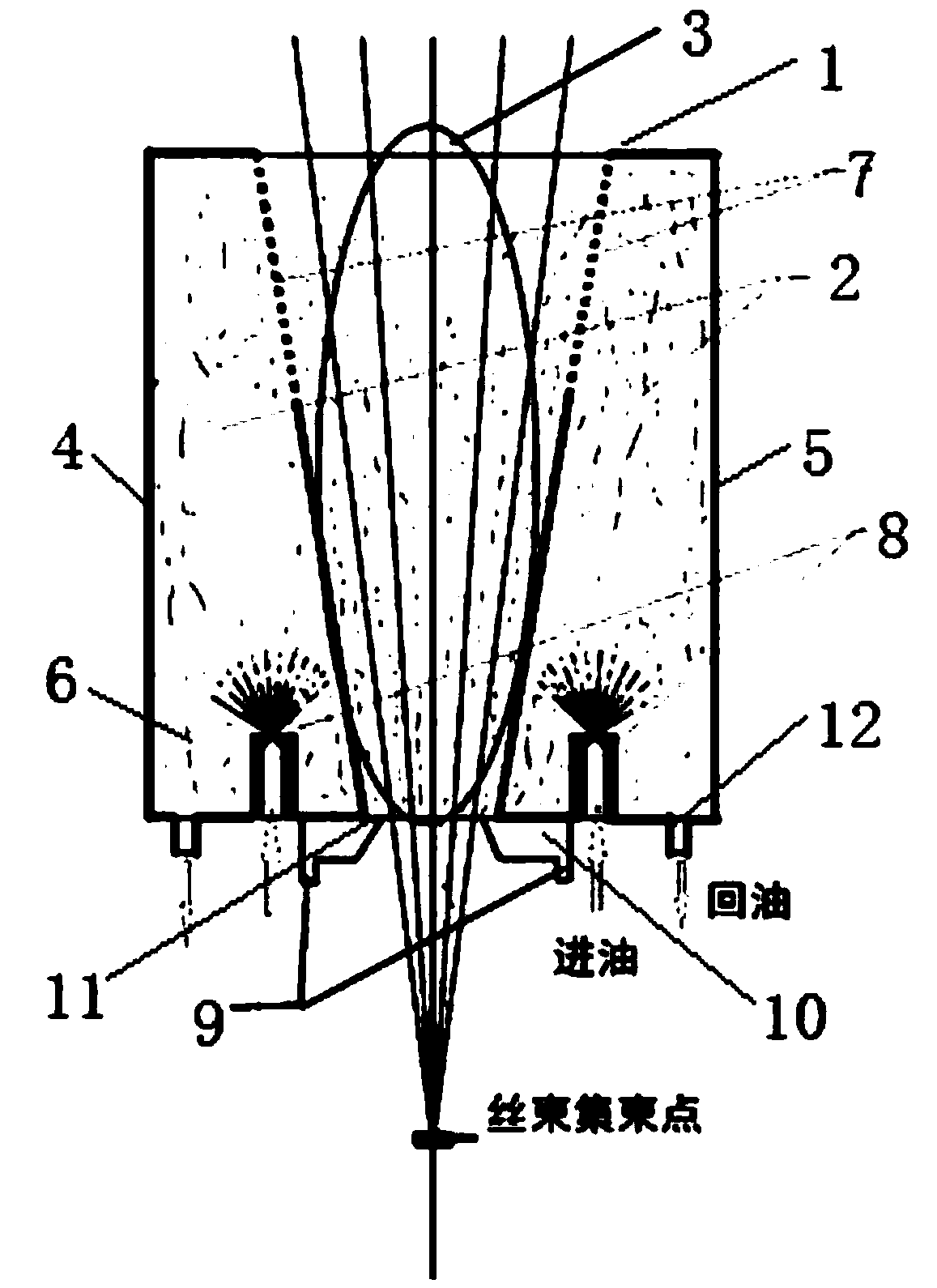

[0048] Such as figure 1 and figure 2 As shown, this embodiment provides a spinning oiling device, including a body, the body has a cavity, the cavity is filled with oil mist, when the spun fiber tow passes through the cavity, the oil in the cavity The mist oils the passing fibers.

[0049] The spinning oiling device in this embodiment is installed below the measuring blowing or surrounding blowing and above the spinning tunnel. After the spinning oil is atomized, the oil mist concentration and range can be controlled and output to the cavity, and the oiling of the tow is completed when the tow passes through this area, forming a non-contact oiling, replacing conventional oil nozzles and oil tankers Oiled spinning overcomes the problems of spinning oiling uniformity and spinning tension fluctuation in the prior art. In this way, all the fiber tows are evenly oiled through the oil mist without direct contact with the oil agent, which ensures the uniformity of oiling of indiv...

Embodiment 2

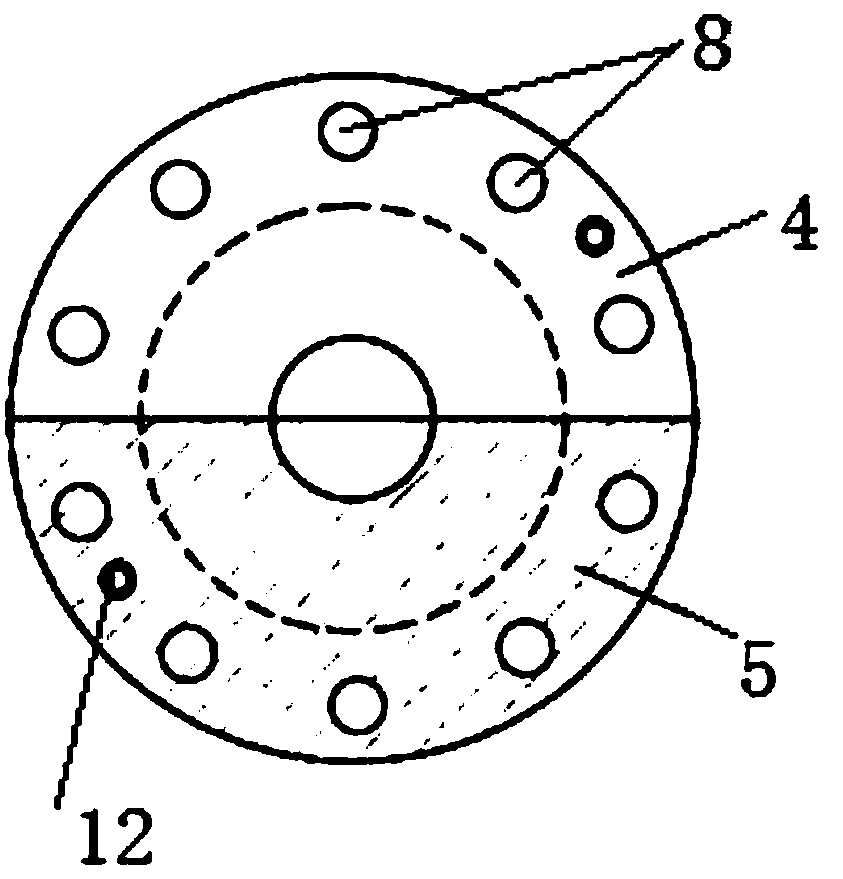

[0053] Such as figure 1 and figure 2 As shown, this embodiment is a further limitation of Embodiment 1. The spinning oiling device of this embodiment includes a body, and the body has a cavity, and the cavity is at least separated into an oil mist concentration area filled with oil mist and The fiber oiling area for the fibers to pass through, the oil mist concentration area is connected with the fiber oiling area, the oil mist in the oil mist concentration area enters the fiber oiling area, and the fibers passing through the fiber oiling area are oiled .

[0054] The cavity in this embodiment is divided into an oil mist concentration area and a fiber oiling area. The oil mist concentration area is concentrated to store the oil mist, and the fiber oiling area is for the fiber to pass through. There are many ways to separate, for example, the oil mist concentration area It is located at least on both sides of the fiber oiling area, or the oil mist concentration area can be l...

Embodiment 3

[0085] This embodiment is a further limitation of Embodiment 1. The difference between this embodiment and Embodiment 2 is that the first oiling part and the second oiling part of this embodiment are integrated and cannot be moved relative to each other, and they form a ring together inside. The hollow chamber, the radial cross-sectional area of the annular hollow chamber gradually increases from bottom to top. The hollow part in the center of the annular hollow chamber forms a fiber oiling area, and when the fiber passes, the oil mist oils the fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com