High-strength and high-modulus carbon fiber and preparation method thereof

A carbon fiber and high modulus technology, applied in the fields of fiber chemical characteristics, rayon chemical post-treatment, textiles and papermaking, etc., can solve problems such as different bulk density, difference in gradient control, difficulty in ensuring the heat resistance of fiber linear molecular chains, etc. Achieve the effect of strong controllability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation method of the high-strength and high-modulus carbon fiber of the present embodiment comprises the following steps:

[0038] (1) The 12K polyacrylonitrile fiber made by the laboratory is used for pre-oxidation treatment in the pre-oxidation furnace with 6 temperature zones. ℃, the fiber draft ratio in the first temperature zone is 2.0%, and the fiber draft ratio in the other temperature zones is -1.5%, the fiber residence time in each temperature zone is 16min, and the fiber body density after pre-oxidation is 1.380g / cm 3 .

[0039] (2) Use a low-temperature carbonization furnace to carry out low-temperature carbonization treatment on the pre-oxidized fiber in six temperature zones. The draft ratio is 4.0%, and the fiber residence time in each temperature zone is 40s;

[0040] Use a high-temperature carbonization furnace to carry out high-temperature carbonization treatment on pre-oxidized fibers in five temperature zones. The temperatures of high-tempe...

Embodiment 2

[0044] The preparation method of the high-strength and high-modulus carbon fiber of the present embodiment comprises the following steps:

[0045] (1) The 12K polyacrylonitrile fiber made by the laboratory is used for pre-oxidation treatment in the pre-oxidation furnace with 6 temperature zones. ℃, the fiber draft ratio in the first temperature zone is 2.0%, and the fiber draft ratio in the other temperature zones is -1.5%, the fiber residence time in each temperature zone is 16min, and the fiber body density after pre-oxidation is 1.375g / cm 3 .

[0046] The operation process and parameters of steps (2)-(3) are the same as those in Example 1.

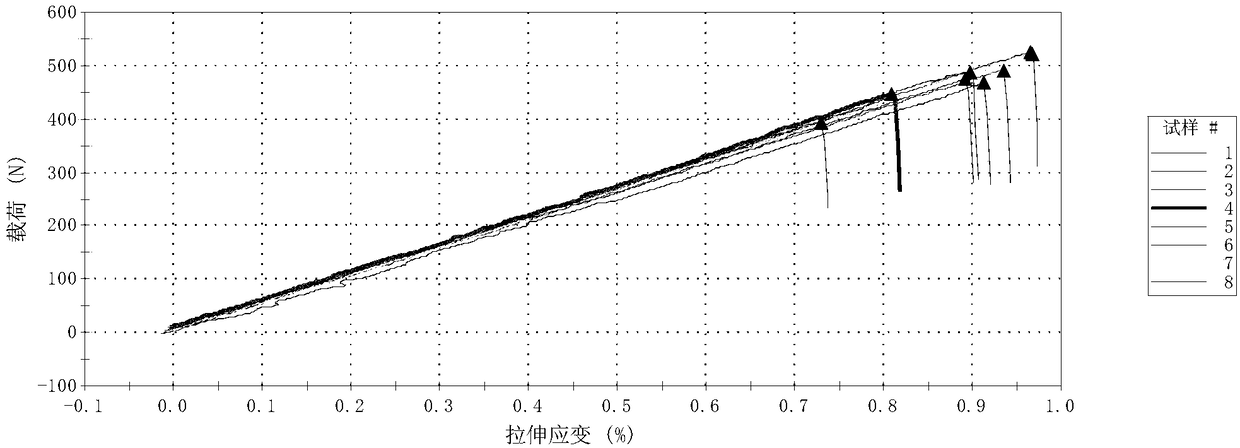

[0047] According to the national standard GB-T3362-2005, the fiber performance is tested, and the tensile curve is as follows image 3 As shown, the carbon fiber tensile strength is 4.52GPa, and the tensile modulus is 522GPa.

Embodiment 3

[0049] The preparation method of the high-strength and high-modulus carbon fiber of the present embodiment comprises the following steps:

[0050] (1) The 12K polyacrylonitrile fiber made by the laboratory is used for pre-oxidation treatment in the pre-oxidation furnace with 6 temperature zones. ℃, the fiber draft ratio in the first temperature zone is 2.0%, and the fiber draft ratio in the other temperature zones is -1.5%, the fiber residence time in each temperature zone is 16min, and the fiber body density after pre-oxidation is 1.370g / cm 3 .

[0051] The operation process and parameters of steps (2)-(3) are the same as those in Example 1.

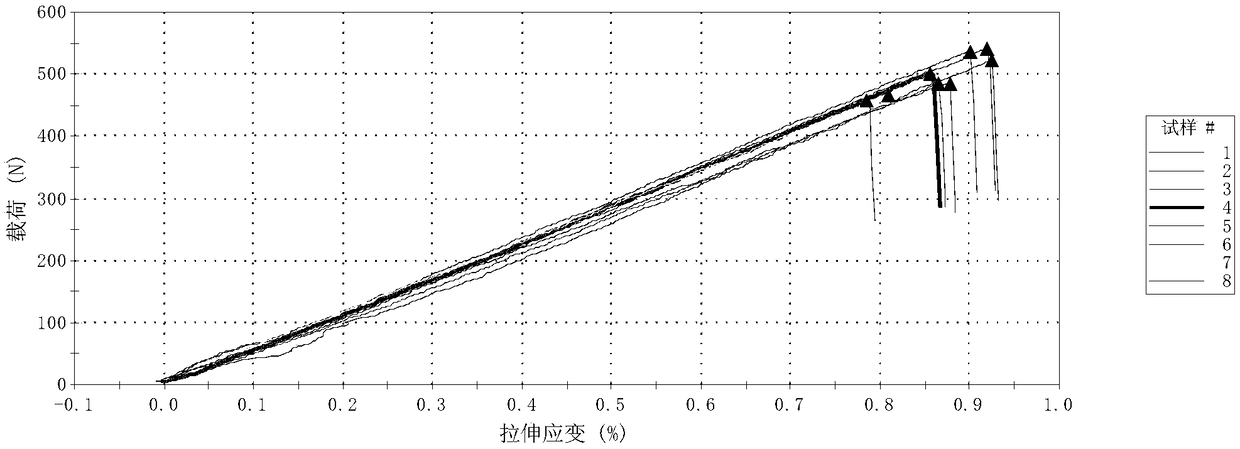

[0052] According to the national standard GB-T3362-2005, the fiber performance is tested, and the tensile curve is as follows Figure 4 As shown, the carbon fiber tensile strength is 4.55GPa, and the tensile modulus is 534GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com