Fabricated spliced light and thin heat insulation formwork

A thermal insulation formwork and prefabricated technology, which is applied in the field preparation of formwork/formwork components and building components, construction, etc., can solve the problems of low degree of industrialization of buildings, heavy weight, and non-environmental protection, so as to improve construction efficiency and shorten the construction time. Time and labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

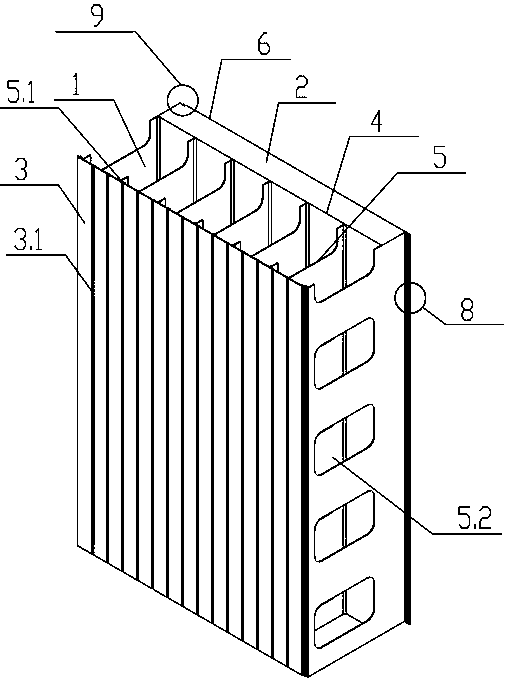

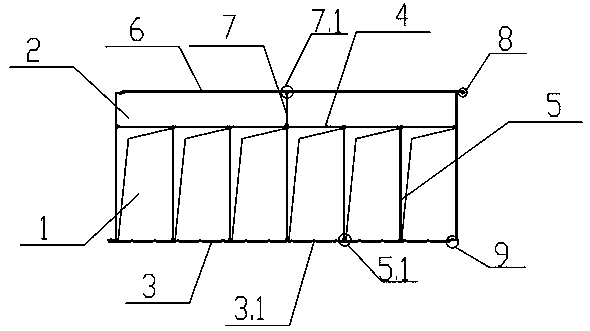

[0034] The present invention is described in detail below in conjunction with accompanying drawing:

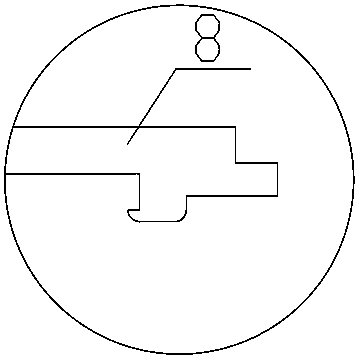

[0035] An assembled and spliced light and thin thermal insulation template, the thermal insulation template includes two cavities, the two cavities are respectively a structural wall pouring cavity 1 and a thermal insulation cavity 2, and the structural wall pouring cavity 1 includes an outer panel 3 and a middle panel 4. The outer panel 3 and the middle panel 4 are connected by a number of first reinforcing rib sheets 5 evenly distributed in the middle, and form a cavity structure;

[0036] The heat preservation cavity 2 includes a middle panel 4 and an inner side panel 6, and the middle panel 4 and the inner side panel 6 are connected by several second reinforcing rib sheets 7 evenly distributed in the middle to form a cavity structure, and the heat preservation cavity 2 is a whole sealed space;

[0037] The structural wall pouring cavity 1 and the thermal insulation cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com