Flaky acoustic black hole energy harvester set device

An energy harvester and black hole technology, which is applied in the fields of vibration reduction and noise reduction, vibration and noise control, can solve the problems of poor low frequency vibration reduction performance, large size of the device, and few adjustment parameters, and achieves economical and convenient manufacturing and small size. , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

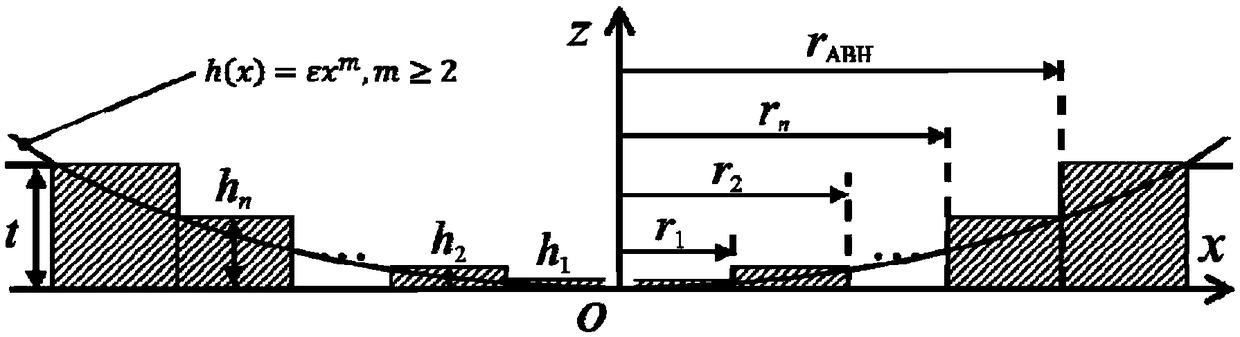

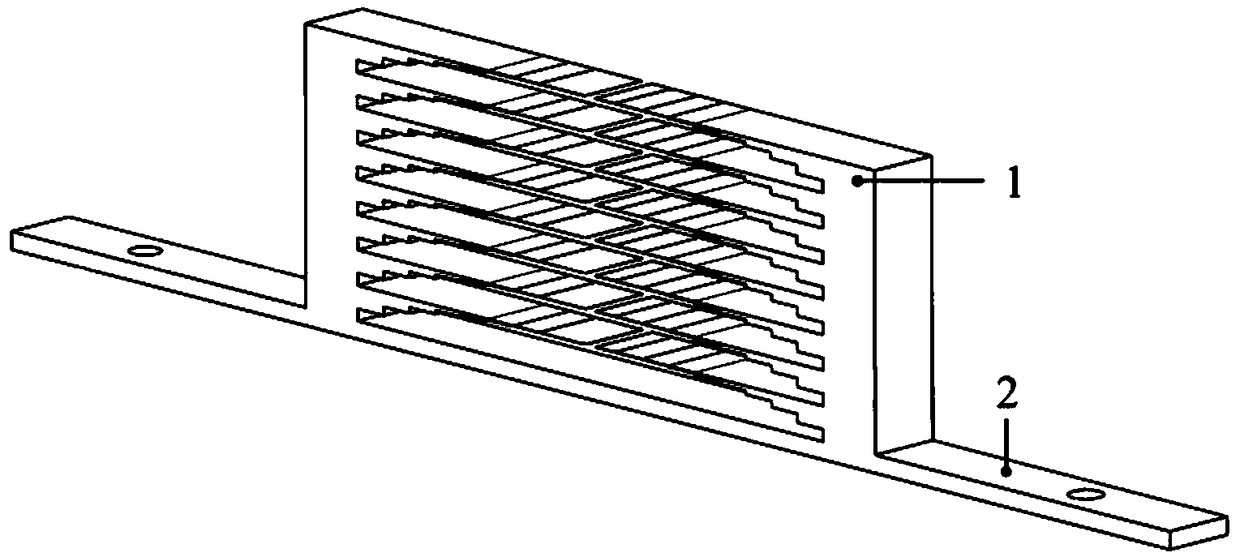

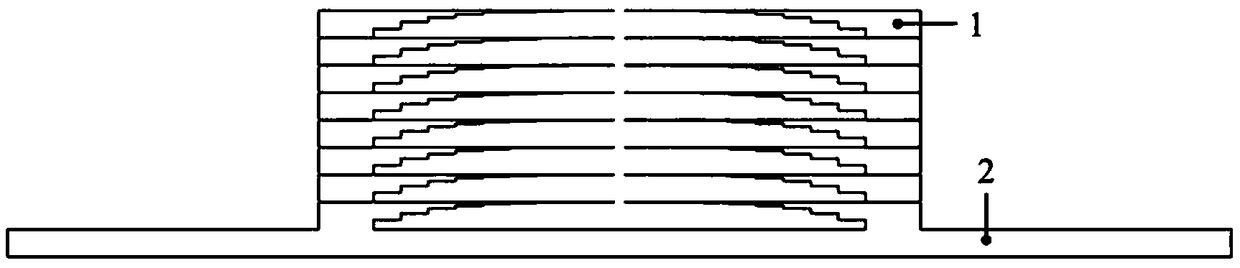

[0062] Such as figure 2 , image 3 Shown is the first embodiment of the sheet-shaped acoustic black hole energy harvester group of the present invention, the present invention provides a kind of sheet-like acoustic black hole energy harvester group device additionally used on the beam, comprising eight acoustic black hole energy harvesters 1 and The lower bottom surface sealing plate 2 of the energy device group. The upper eight acoustic black hole energy harvesters 1 are bonded and connected in sequence; the lowermost acoustic black hole energy harvester is bonded and connected to the lower bottom sealing plate 2 of the energy harvester group; the eight acoustic black hole energy harvesters 1 are connected to the lower surface of the energy harvester group The bottom sealing plate 2 is welded and connected to form an integral acoustic black hole energy harvester group; the lower bottom sealing plate 2 of the energy harvester group is a uniform and flat rectangular plate, wh...

no. 2 example

[0067] Such as Figure 4 , Figure 5 Shown is the second embodiment of the sheet-shaped acoustic black hole energy harvester group of the present invention, the present invention provides a kind of sheet-like acoustic black hole energy harvester group device additionally used on the plate frame, comprising eight acoustic black hole energy harvesters 1 and The lower bottom surface sealing plate 2 of the energy harvester group. The upper eight acoustic black hole energy harvesters 1 are bonded and connected in sequence; the lowermost acoustic black hole energy harvester is bonded and connected to the lower bottom sealing plate 2 of the energy harvester group; the eight acoustic black hole energy harvesters 1 are connected to the lower surface of the energy harvester group The bottom sealing plate 2 is welded and connected to form an integral acoustic black hole energy harvester group; the lower bottom sealing plate 2 of the energy harvester group is a uniform and flat rectangul...

no. 3 example

[0071] Such as Figure 6 , Figure 7 Shown is the third embodiment of the sheet-shaped acoustic black hole energy harvester group of the present invention, the present invention provides a kind of sheet-like acoustic black hole energy harvester group device additionally used on the cylindrical outer surface (such as the outer surface of a submarine), comprising eight A block of acoustic black hole energy harvester 1 and a lower bottom sealing plate 2 of the energy harvester group. The upper eight acoustic black hole energy harvesters 1 are bonded and connected in sequence; the lowermost acoustic black hole energy harvester is bonded and connected to the lower bottom sealing plate 2 of the energy harvester group; the eight acoustic black hole energy harvesters 1 are connected to the lower surface of the energy harvester group The bottom sealing plate 2 is welded and connected to form an integral acoustic black hole energy harvester group; the lower bottom sealing plate 2 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com