Unified mode control method for non-inverting Buck-Boost converter

A mode control and converter technology, applied in control/regulation systems, conversion of DC power input to DC power output, instruments, etc., can solve problems such as poor dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

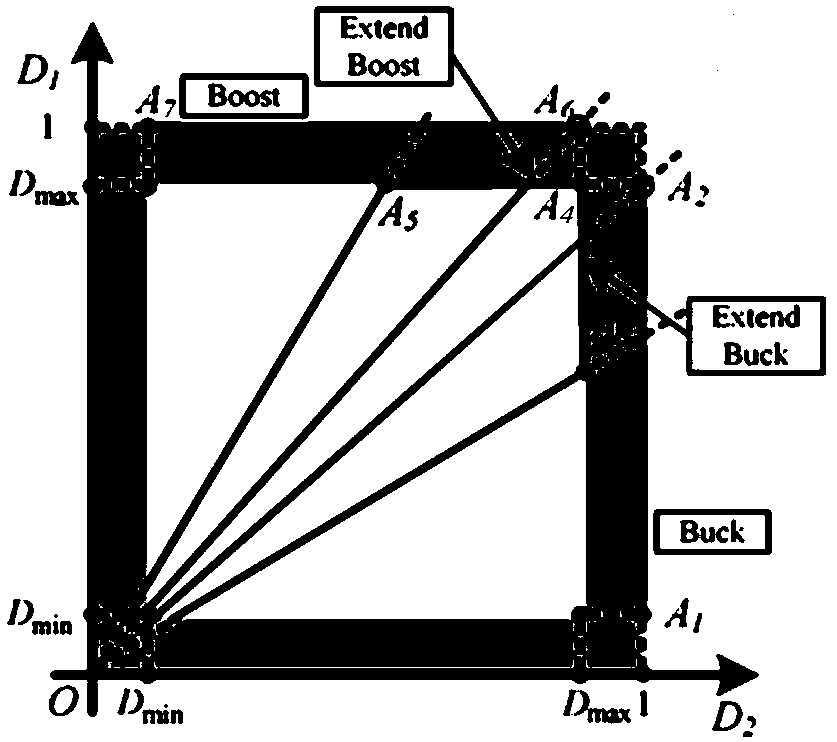

Method used

Image

Examples

Embodiment 1

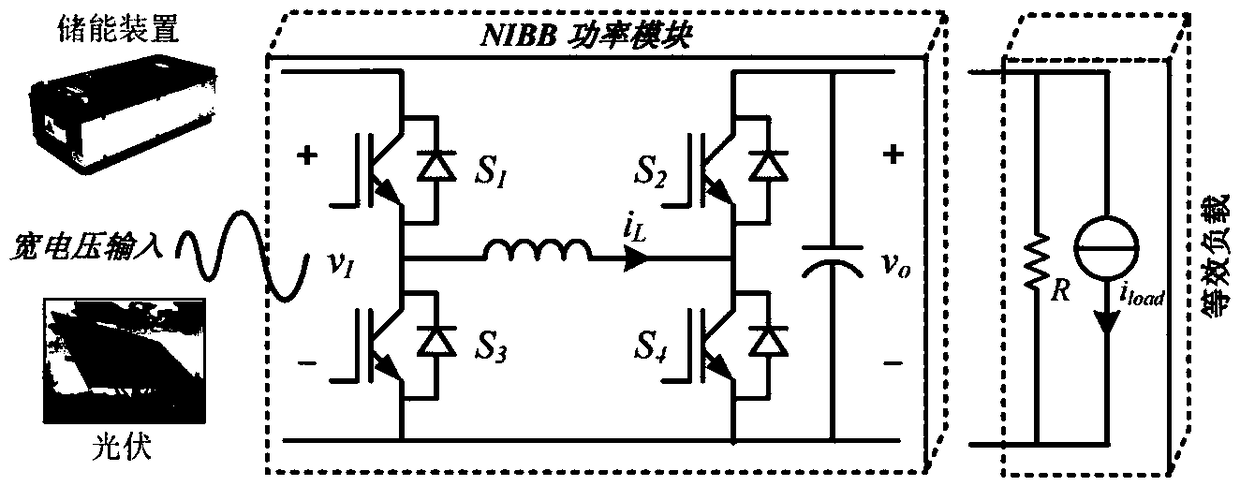

[0147] For example figure 1 The shown NIBB circuit diagram is simulated, and the parameters of each component of the circuit are: C=1mF, L=1mH, R=20Ω. According to the circuit parameters, take V in = 48V. The unified mode controller designed based on LMI is [-0.93,-2.9,-587].

[0148] In order to verify the effectiveness of the unified mode controller, the design and Figure 6 Equivalent discrete-mode controllers such as Figure 8 shown. The inner loop uses proportional control and the outer loop uses PI control. The control parameter is set to: k vp =3,k vi =540,k ip = 0.16.

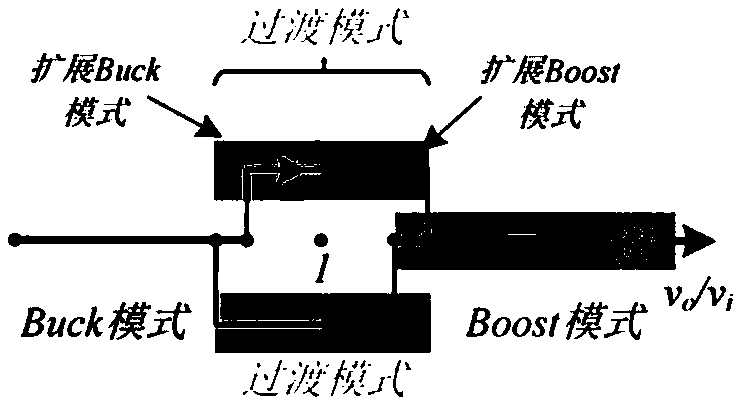

[0149] The performance of unified mode control and discrete mode control is compared under load ramping and load ramping conditions. During simulation, use numbers to represent each working mode of NIBB, among which 1 represents Buck mode, 2 represents extended Buck mode, 3 represents extended Boost mode, and 4 represents Boost mode.

[0150] 1) Response when the load increases

[0151] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com