Sludge (or slit) pond floating greening treatment process structure

A treatment process, pond-floating technology, applied in the field of sludge (or silt) pond-floating greening treatment process structure, can solve the problem of inability to directly enter planting plants, and achieve the goal of reducing carbon emissions, accelerating growth, and developing a broad space for development. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

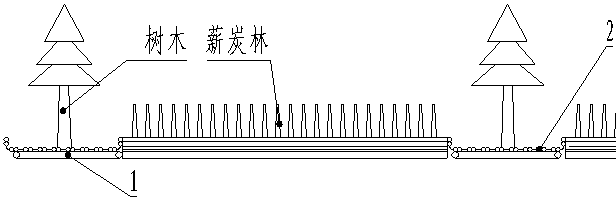

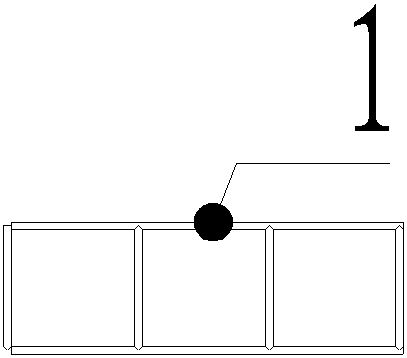

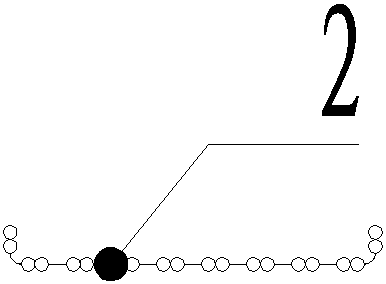

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. A sludge (or silt) pond floating greening treatment process structure, characterized in that the present invention is a floating raft tray structure composed of a supporting frame and a main structure, and sludge (or silt) is placed in the floating raft tray structure , Plant seedlings with different growth heights in different parts of the floating raft tray to form an interplanting mode. The plant seedlings grow in the floating raft tray, and after the degradation of the floating raft tray structure, the plant seedlings slowly grow in the sludge (or silt) ) pond, to absorb various substances that can be absorbed by plants such as water and nutrients in the sludge (or silt) pond.

[0020] A sludge (or silt) pond floating greening treatment process structure, characterized in that the present invention is a floating raft tray structure (3) compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com