Casting method of automobile steering knuckle

An automobile steering knuckle and casting method technology, which is applied in the directions of casting molds, casting mold components, casting molding equipment, etc., can solve the problems of sand holes or slag holes, high production costs, and increased thermal energy coefficient of thermal saving, and achieves a reduction in the Production cost, improve product quality, eliminate shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention can be explained in more detail by the following examples, and the present invention is not limited to the following examples;

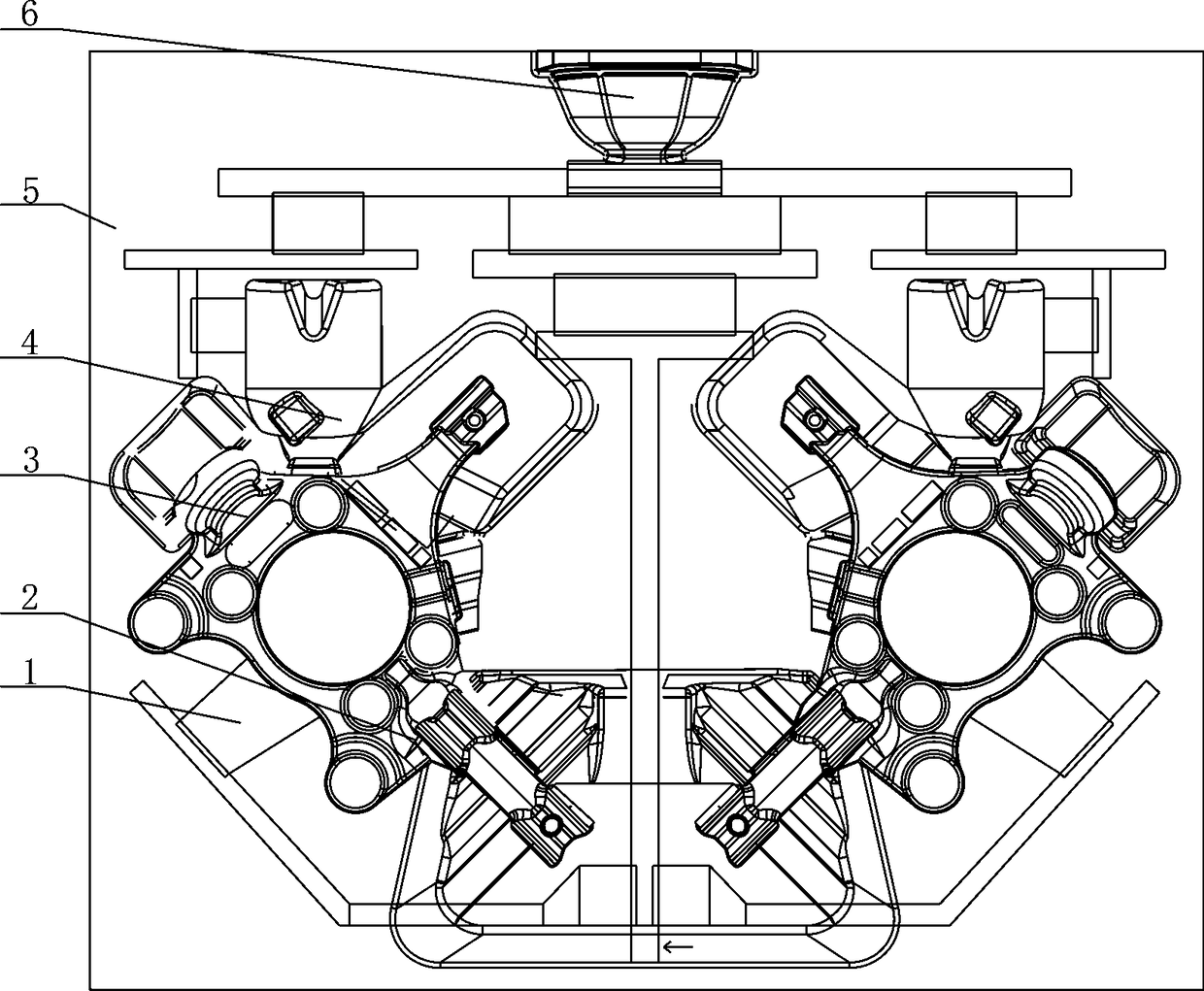

[0017] combined with figure 1 The above-mentioned casting method of an automobile steering knuckle, the casting method firstly sets the steering knuckle cavity on the mold body 5 obliquely, and the inclination angle of the steering knuckle cavity is 30° to 60°, preferably 45° °, the top of the mold body 5 is provided with a main gate 6, and two mutually symmetrical steering knuckle cavities are arranged on the mold body 5, and sub-gates are respectively provided at the positions of the caliper mounting holes in the middle of each steering knuckle cavity 1. Each of the sub-gates 1 is connected to the main gate 6 through a runner, and the sub-gates 1 are connected to the overflow port through a pipeline; an overheating riser 4 is set at the part 3 of the hot joint B, and at the same time when turning A sub-gate 1 is added ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com