Method for synthesizing gold nanoparticles through microemulsion without surfactant

A technology without surfactants and gold nanoparticles, applied in the direction of nanotechnology, can solve the problems of increasing procedures and costs, and achieve the effects of low cost, simple steps in the synthesis process, and narrow size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

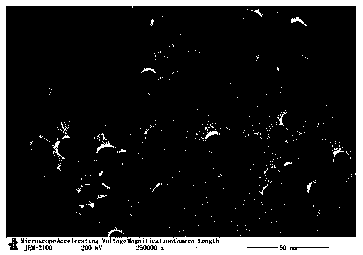

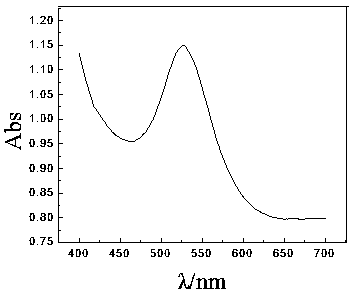

Image

Examples

Embodiment 1

[0022] A method for synthesizing gold nanoparticles from a surfactant-free microemulsion. The preparation steps are as follows: (1) Mix the oil phase solvent, the water phase solvent A, and the two solvents uniformly at room temperature, and stir at room temperature until the mixed liquid Transparent to obtain microemulsion A, the stirring speed is 225r / min; (2) Mix the oil phase solvent, water phase solvent B, and double solvent at room temperature, and stir at room temperature until the mixture is clear to obtain microemulsion B, stirring The speed is 225r / min; (3) Slowly add an equal volume of microemulsion B into microemulsion A from a constant pressure funnel under stirring, and continue to stir at 15°C for 15 hours, and the dropping speed is 65 drops / min.

[0023] Preferably, the oil phase solvent is oleic acid.

[0024] Preferably, the aqueous phase solvent A is 10.25mmol L -1 chloroauric acid solution.

[0025] Preferably, the aqueous phase solvent B is 0.015-0.03 mo...

Embodiment 2

[0030] A method for synthesizing gold nanoparticles from a surfactant-free microemulsion. The preparation steps are as follows: (1) Mix the oil phase solvent, the water phase solvent A, and the two solvents uniformly at room temperature, and stir at room temperature until the mixed liquid Transparent to obtain microemulsion A, the stirring speed is 275r / min; (2) Mix the oil phase solvent, water phase solvent B, and double solvent at room temperature, and stir at room temperature until the mixture is clear to obtain microemulsion B, stirring The speed is 275r / min; (3) Slowly add an equal volume of microemulsion B to microemulsion A from a constant pressure funnel under stirring, and continue to stir at 15°C for 15h, the dropping speed is 60 drops / min.

[0031] Preferably, the oil phase solvent is a mixture of oleic acid and ethyl oleate, and the oil phase solvent is a mixture of oleic acid and ethyl oleate in a mass ratio of 5:1.

[0032] Preferably, the aqueous phase solvent B...

Embodiment 3

[0038] A method for synthesizing gold nanoparticles from a surfactant-free microemulsion. The preparation steps are as follows: (1) Mix the oil phase solvent, the water phase solvent A, and the two solvents uniformly at room temperature, and stir at room temperature until the mixed liquid Transparent to obtain microemulsion A, the stirring speed is 230r / min; (2) Mix the oil phase solvent, water phase solvent B, and double solvent at room temperature, and stir at room temperature until the mixture is clear to obtain microemulsion B, stirring The speed is 230r / min; (3) Slowly add an equal volume of microemulsion B into microemulsion A from a constant pressure funnel under stirring, and continue to stir at 15°C for 15h, the dropping speed is 65 drops / min.

[0039] Preferably, the oil phase solvent is a mixture of oleic acid, methyl oleate, and ethyl oleate, and the volume ratio of the oleic acid, methyl oleate, and ethyl oleate is 4:1:1.

[0040] Preferably, the concentration rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com