A milling machine capable of automatic cycle cooling

An automatic cycle and cycle cooling technology, applied in the field of milling machines, can solve the problems of unfavorable milling head rotation and easy generation of high temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

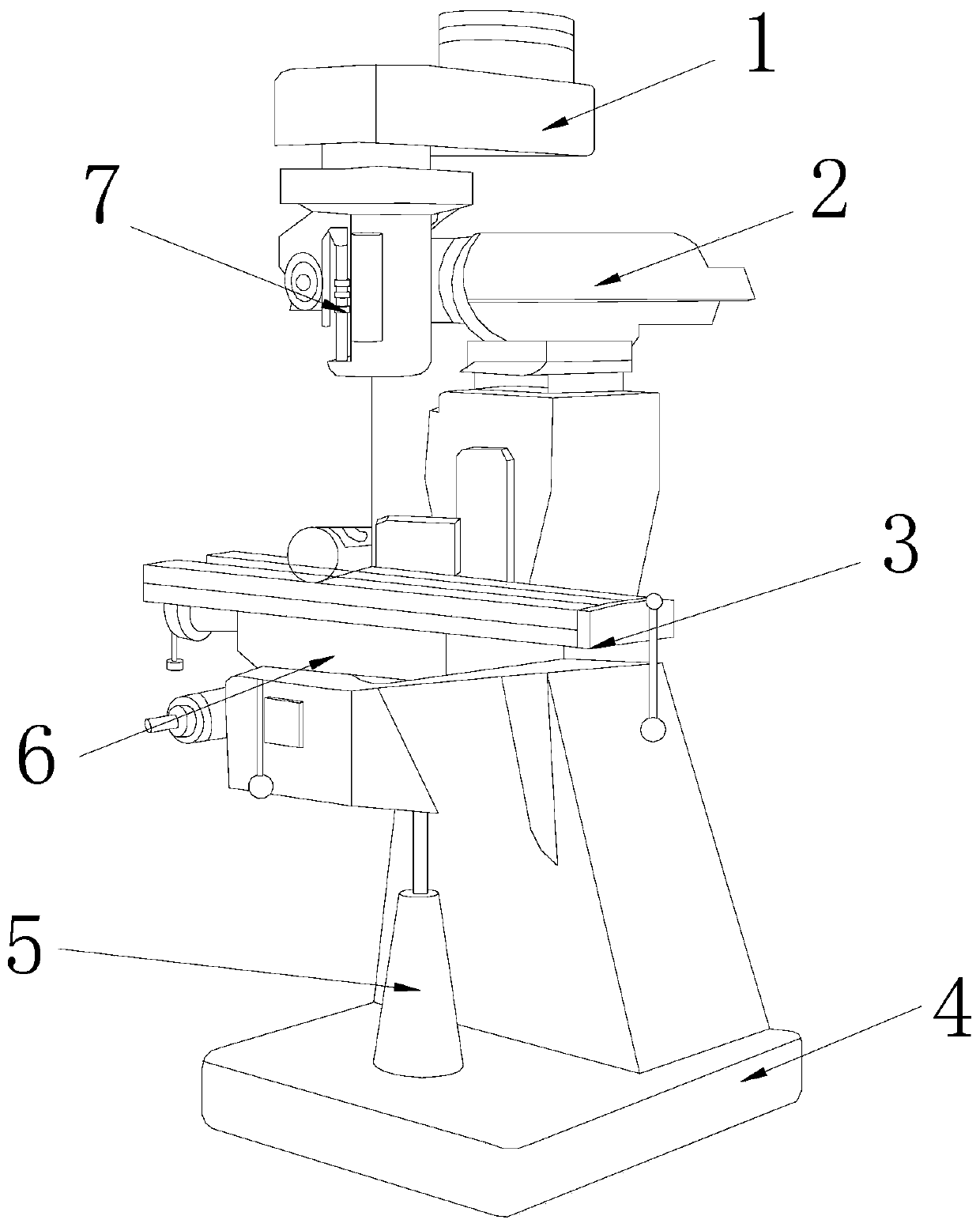

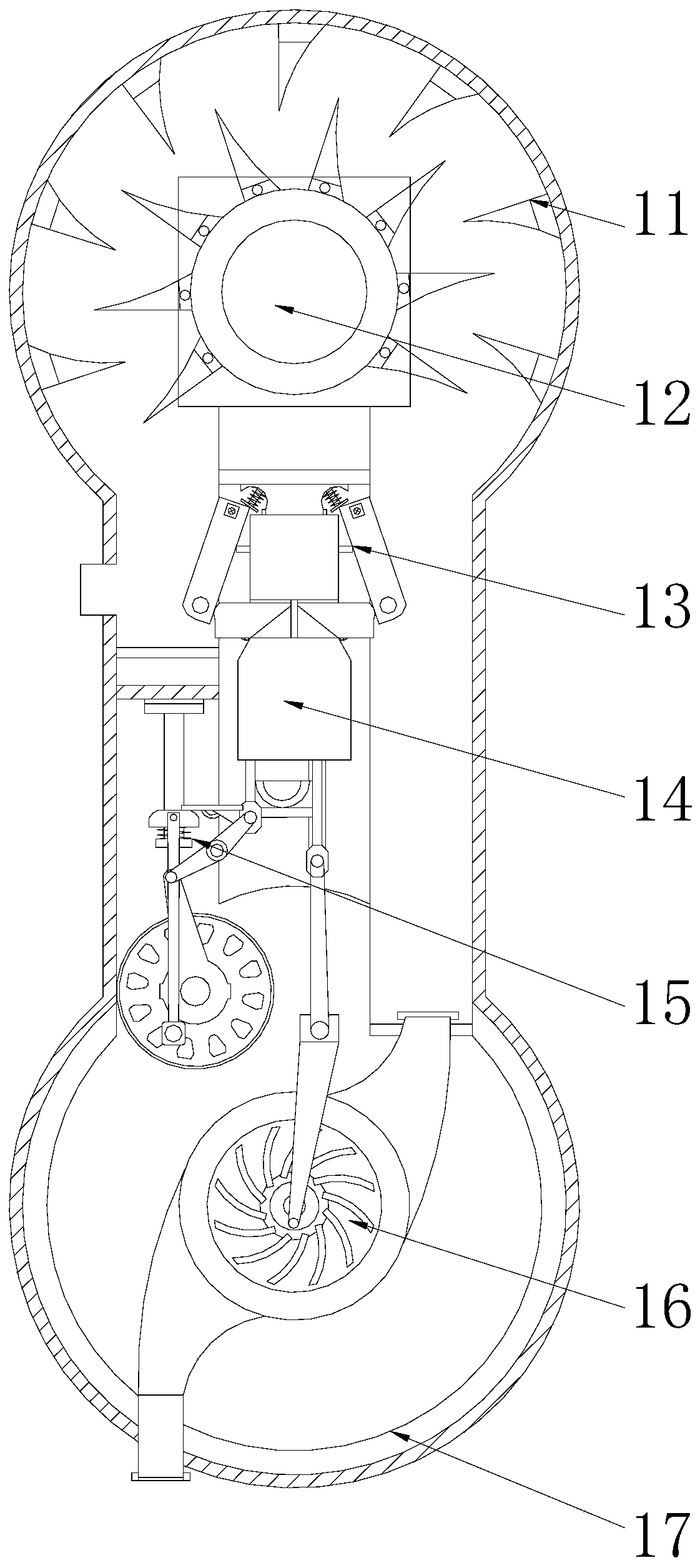

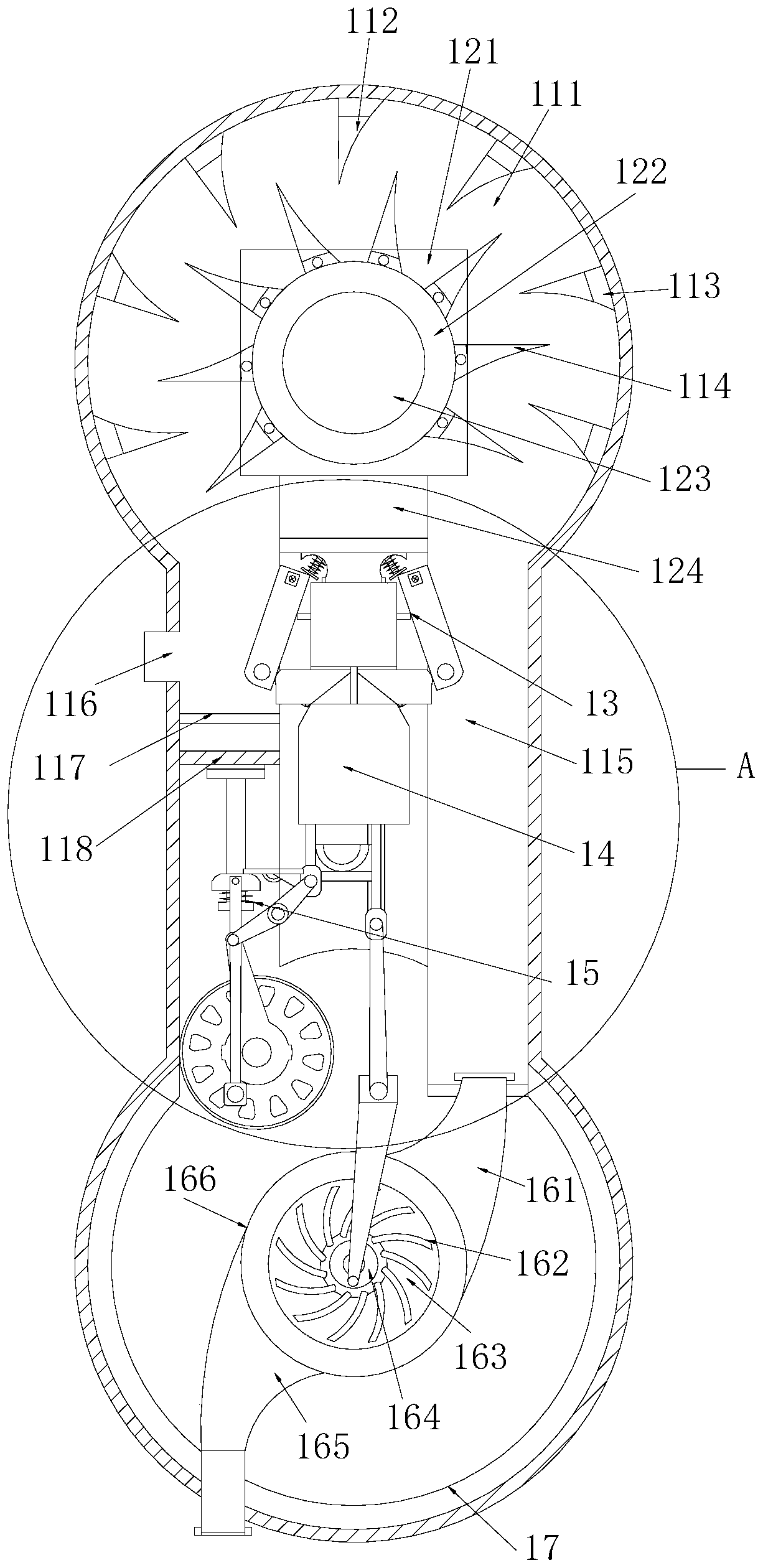

[0022] see Figure 1-Figure 4 , the present invention provides a milling machine capable of automatic cycle cooling, the structure of which includes a cycle cooling mechanism 1, a bed 2, a longitudinal table 3, a base 4, a lifting table 5, a horizontal table 6, and a main shaft 7, and on the base 4 A longitudinal workbench 3 and a transverse workbench 6 are vertically fixed, and a lifting platform 5 is also installed between the longitudinal workbench 3 and the base 4, and a bed 2 is also fixed on the longitudinal workbench 3, and the bed 2 A main shaft 7 is installed on it, and a circulating cooling mechanism 1 is installed between the main shaft 7 and the bed 2, and the circulating cooling mechanism 1 is provided with a diversion structure 11, an installation structure 12, an automatic opening structure 13, a pushing structure 14, Back pressure structure 15, air flow conversion structure 16, device housing 17, installation structure 12 and air flow conversion structure 16 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com