Mechanical arm edge grinding machine for rearview mirror lens machining

A lens processing and manipulator technology, applied in the field of mechanical equipment, can solve problems such as difficult large-scale promotion, unstable lens material delivery, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

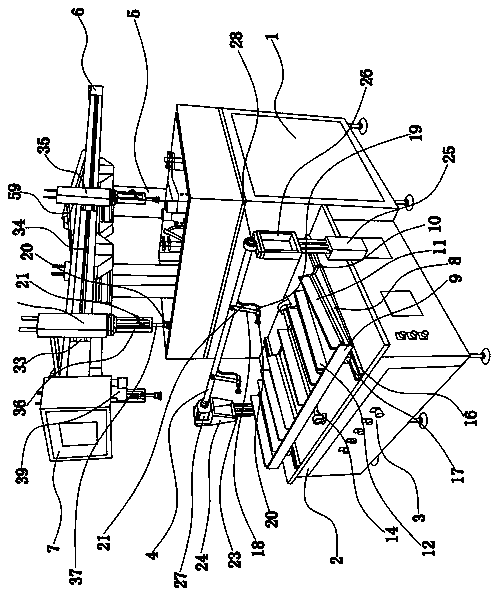

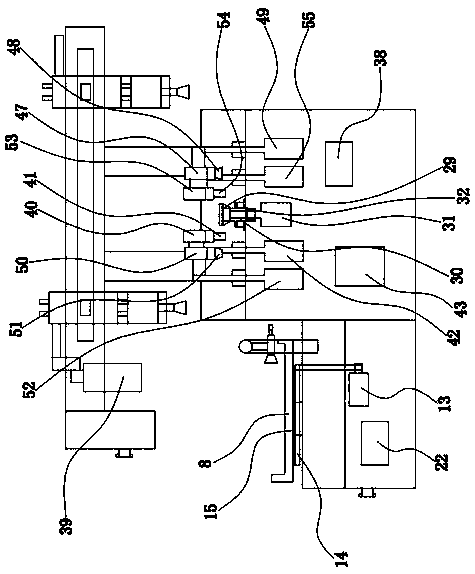

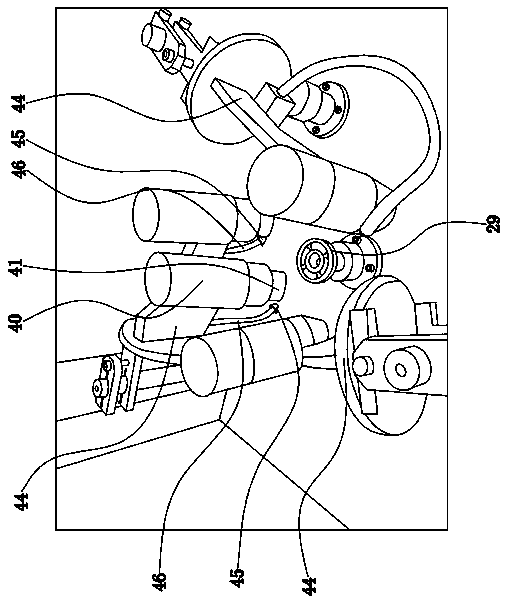

[0028] Such as figure 1 , figure 2 , image 3 and Figure 4As shown, the manipulator edging machine used for rearview mirror lens processing is mainly composed of a main body 1 and an auxiliary body 2. There is a control cabinet 3 under the sub-body 2, and a central processor controls the whole machine in the control cabinet 3. For the operation of the machine, a feed tray is arranged horizontally on the table of the auxiliary body 2 parallel to the table tops of the auxiliary body 2, and a driving device for guiding and sliding the feed tray is provided between the feed tray and the 2 table tops of the auxiliary body; during actual manufacture, the The specific structure of the material tray is: mainly composed of a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com