Control method of electric vehicle for mining

A mine-used electric vehicle and control method technology, applied in the direction of electric vehicles, control drives, control devices, etc., can solve problems affecting cruising range, high emissions, battery damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

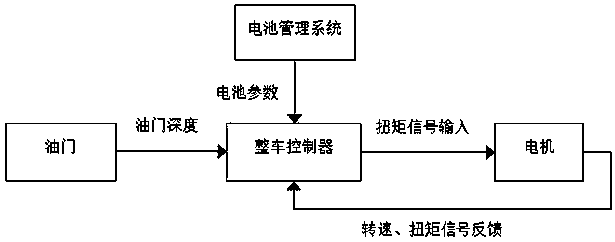

[0028] The control method of a mining electric vehicle in this embodiment is applied to a mining electric vehicle, see figure 1 , the mine electric vehicle includes throttle, battery management system, motor and vehicle controller, the model of the vehicle controller is ECM-5554-112, the motor has a motor controller, and the model of the motor controller can be KBC-50 / 384C or NBK93 / 320C. The throttle, the battery management system, and the motor controller are all electrically connected to the vehicle controller, and the control method includes the following steps:

[0029] [1] To make the mining electric vehicle run under ideal conditions, the vehicle controller calculates the target vehicle speed V according to the accelerator pedal depth θ stepped on by the driver d ,Specifically: where V max Design maximum speed for the vehicle, θ max is the maximum depth of the accelerator; according to the transmission ratio of the mining electric vehicle, set the target vehicle sp...

Embodiment 2

[0033] The control method of a mining electric vehicle in this embodiment is applied to a mining electric vehicle, see figure 1 , the mine electric vehicle includes throttle, battery management system, motor and vehicle controller, the model of the vehicle controller is ECM-5554-112, the motor has a motor controller, and the model of the motor controller can be KBC-50 / 384C or NBK93 / 320C. The throttle, the battery management system, and the motor controller are all electrically connected to the vehicle controller, and the control method includes the following steps:

[0034] [1] To make the mining electric vehicle run under ideal conditions, the vehicle controller calculates the target vehicle speed V according to the accelerator pedal depth θ stepped on by the driver d ,Specifically: where V max Design maximum speed for the vehicle, θ max is the maximum depth of the accelerator; according to the transmission ratio of the mining electric vehicle, set the target vehicle sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com