Preparation method of refractory tungsten carbide WC+W2C spherical powder

A technology of spherical powder and tungsten carbide, which is applied in the field of powder metallurgy to achieve the effect of eliminating direct contact, improving crack resistance and increasing durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

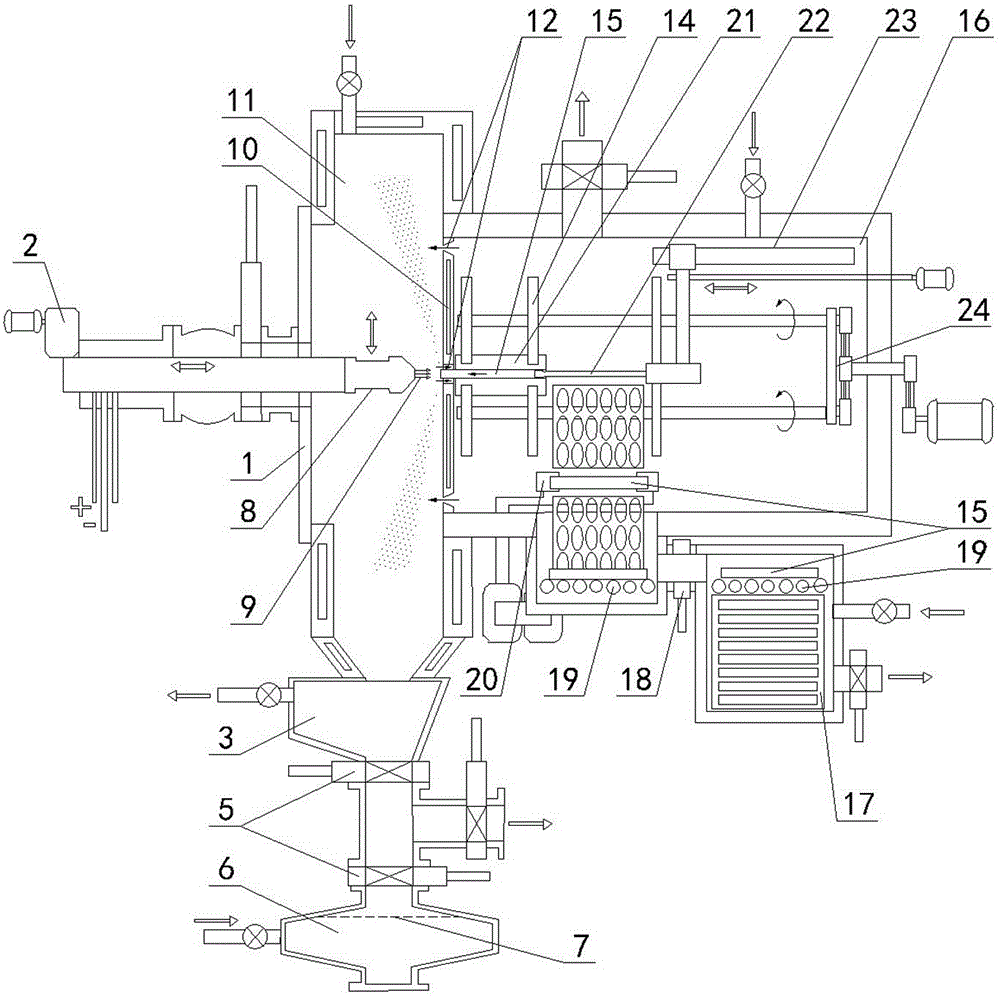

[0030] Such as figure 1 Shown, the present invention prepares refractory tungsten carbide WC+W 2 The method of C spherical powder is as follows:

[0031] The tungsten carbide rod material 15 enters the rod material preheating device 20 from the rod material bin 17 in the form of a round rod through the gate valve 18 through the gate valve 18 in the form of a round rod according to a given composition. The rod material preheating device 20 is a current heating device or a resistance heating device. The tungsten carbide rod 15 is heated to 0.2-0.6 of the melting point temperature by a current or resistance heating device. Then, using the rod moving mechanism 23, under the retraction of the push rod 22 of the rod moving mechanism 23, the preheated tungsten carbide rod 15 is placed into the slitting support 21 with a longitudinal slit of the rod rotating mechanism 24 , and one end of the tungsten carbide rod 15 is extended into the atomization chamber 11 along the slitting brack...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com