Preparation device and method for cohesionless soil sample for geotechnical test

A geotechnical test, non-cohesive soil technology, applied in the field of indoor geotechnical testing of geotechnical engineering, can solve the problem of uneven soil density in the top area of the sample, damage to non-cohesive soil samples, and difficulty in obtaining non-cohesive soil samples, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

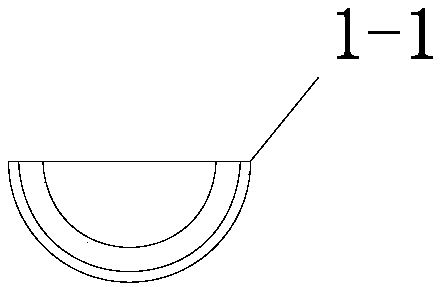

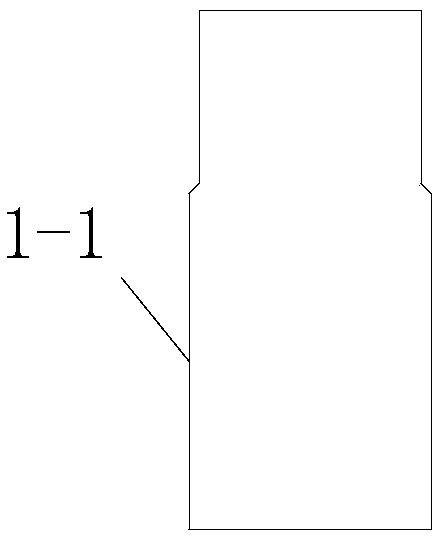

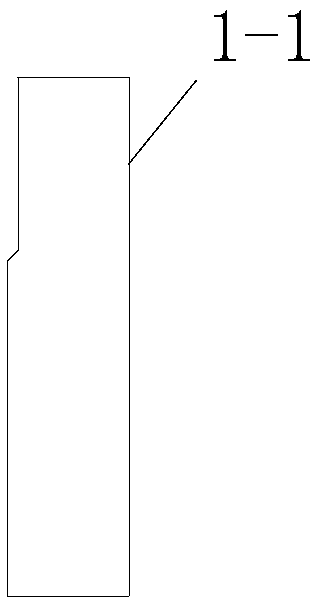

[0074] A preparation device for cohesion-free soil samples for geotechnical tests provided by the present invention comprises a sample filling part 1, a sample compacting part 2, a sample pre-saturation part and a vacuum pumping part; the sample filling part 1 includes a first One pair of open dies 1-1, second pair of open dies 1-2, bottom collar 1-3, top collar 1-4, first ring hoop 1-5, second ring hoop 1-6, first rubber Ring 1-7, the second rubber ring 1-8, rubber membrane 1-9; as Figure 1(a)-Figure 1(c) , Figure 2(a)-Figure 2(c) As shown, the inner walls of the first split mold 1-1 and the second split mold 1-2 are provided with air guide grooves; the middle part of the second split mold 1-2 is provided with air holes 1-2-4 ; The first split mold 1-1 and the second split mold 1-2 are aligned and connected up and down through the first a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com