A diagnosis method and system based on machine failure

A diagnostic method and technology for machine faults, applied in instruments, computer parts, and pattern recognition in signals, etc., can solve problems such as noise pollution, gear tooth manufacturing errors, affecting the accuracy of fault diagnosis, and achieve the effect of improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

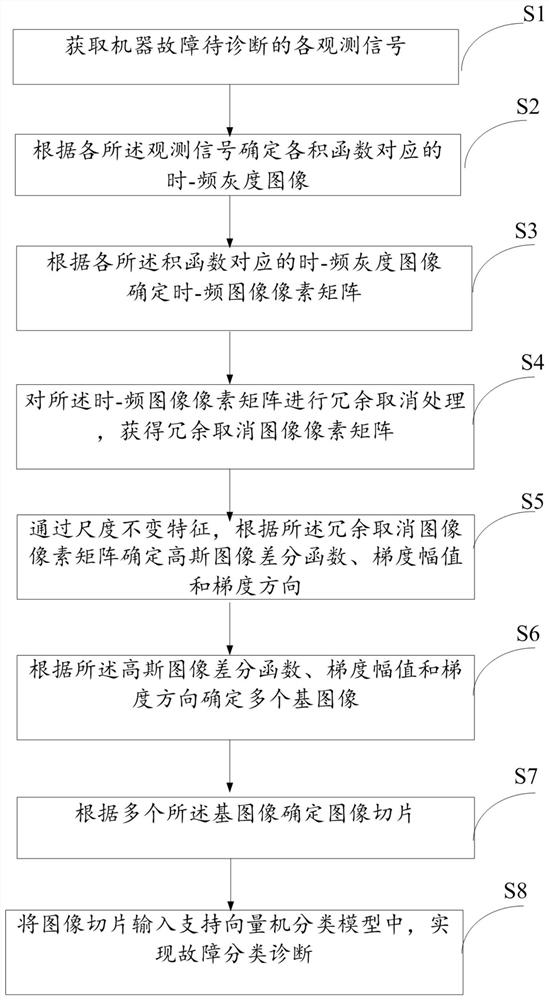

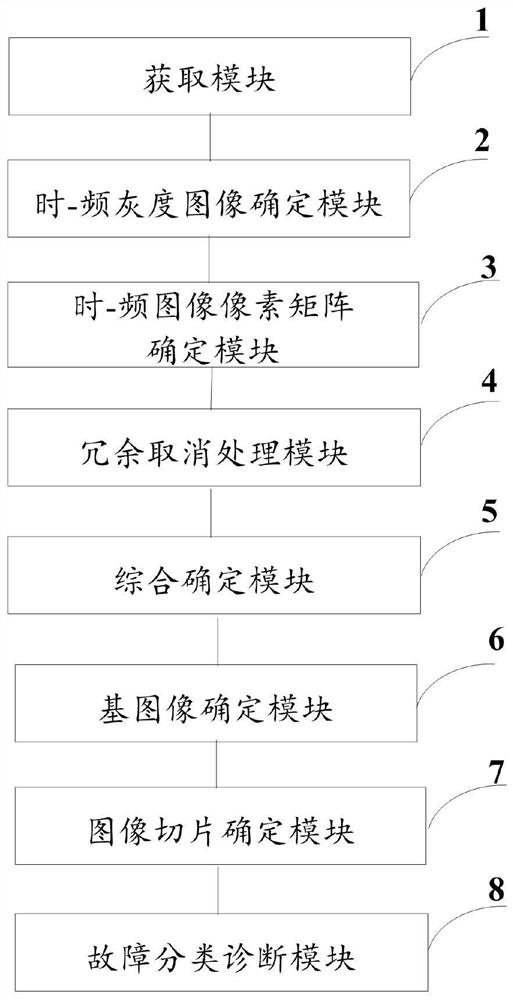

Method used

Image

Examples

Embodiment 1

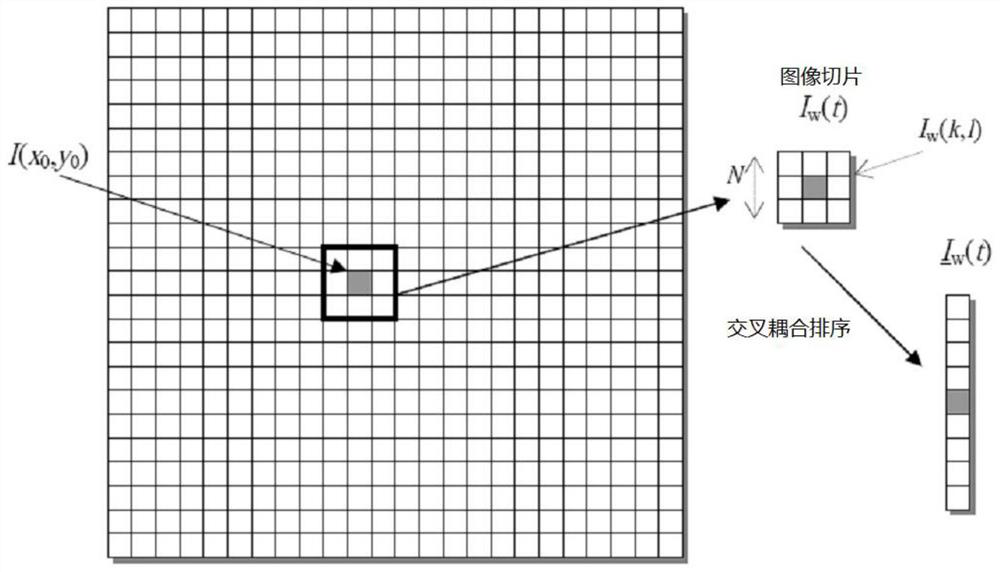

[0107] Redundancy cancellation and scale-invariant feature change fusion based on independent component analysis:

[0108] Assuming that C time-frequency distribution image redundancy cancels the training set Γ c ={x (k) ,k=1,2,…,K},c=1,2,…,C belong to different pattern classes, here x (k) is the kth pixel component training sample, and c is the training set number, that is, the corresponding pattern class number. K is the training set capacity, that is, the number of training samples contained in each training set. According to the following learning rules, the kth training sample x (k) A linear transformation estimate W can be obtained (k) .

[0109] ΔW (k) ∝[(W (k-1) ) T ] -1 +(1-2y (k) )(x (k) ) T

[0110]

[0111] Finally, C ICA redundancy cancellation networks W can be obtained from a given training set of C different pattern classes c =W (K),c=1,2,...,C. These trained networks jointly constitute an image pixel information redundancy canceller, which i...

Embodiment 2

[0119] Training of Independent Component Analysis Redundancy Cancellation Network and Fault Identification and Diagnosis Based on Optimal Support Vector Machine Classification

[0120] The following global separation-mixing matrix is used as a measure to evaluate the training convergence performance of the ICA redundancy cancellation network:

[0121]

[0122] where b ij 、a ij are the elements in the global mixing matrix B and separation matrix A respectively, and ||·|| is a 2-norm function. From Figure 4 It can be seen that the modular parameter of the global mixing-separation matrix BA corresponding to the convergent ICA redundancy cancellation network converges to 0, while the corresponding part of the non-converging network converges to 1. If the convergence and divergence of the measurement parameters are uncertain, the step size and the total number of iterations of network training need to be adjusted.

[0123] The inner product kernel of support vector machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com