Battery assembly with constant operating temperature

A technology of working temperature and combination, applied in battery pack components, secondary batteries, and isolation of batteries from their environment, etc., can solve the problems of reliability and safety impact, weak cooling effect, and high ambient temperature requirements. Good cooling effect, strong cooling effect, significant cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

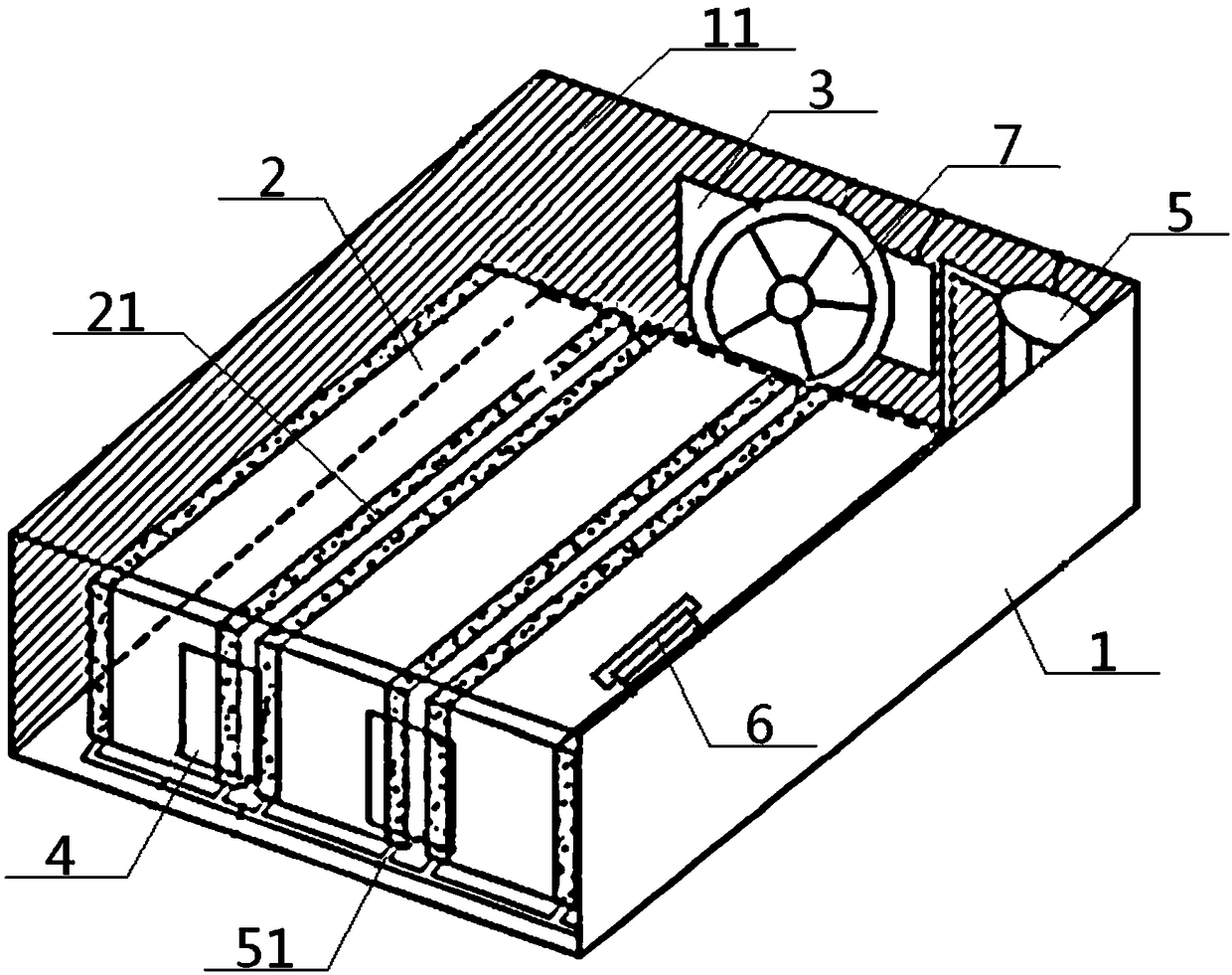

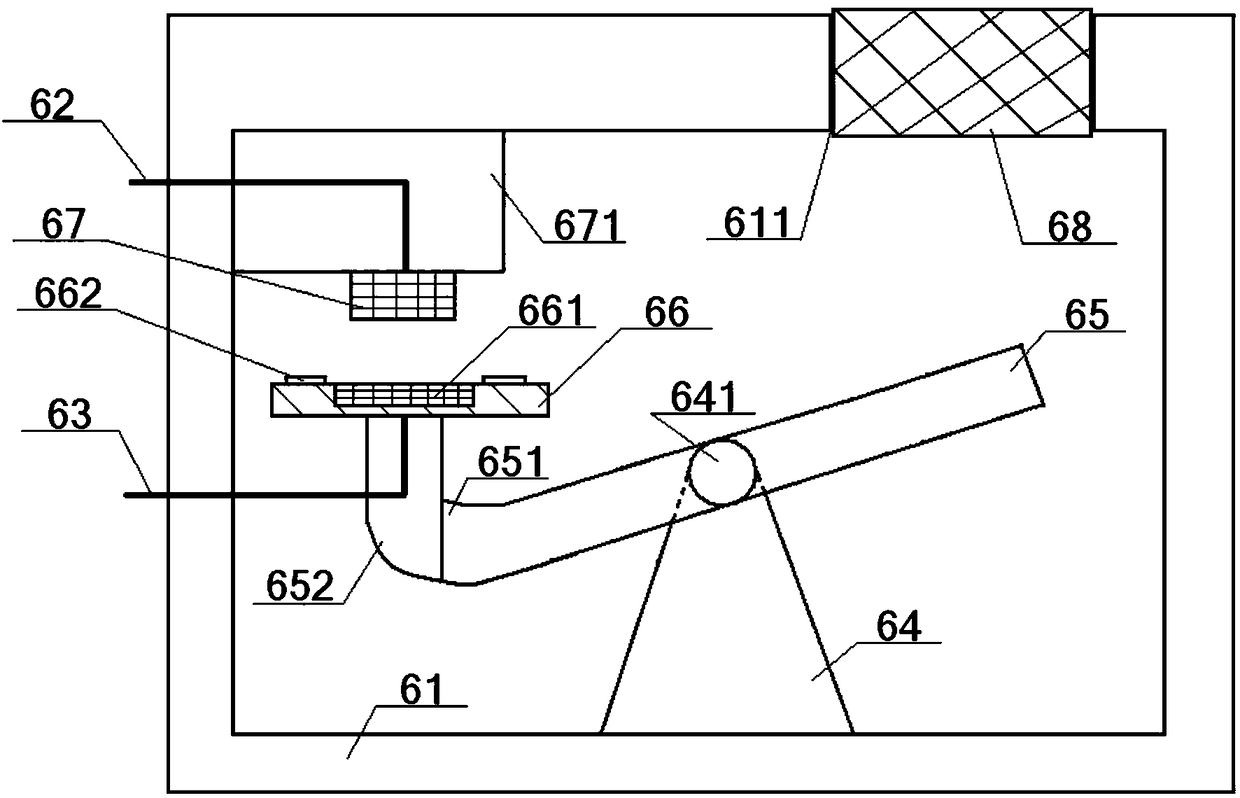

[0030] A battery assembly with a constant working temperature, including a battery box 1, a power battery 2 and a cooling device, the power battery 2 is located in the middle of the battery box 1, and a cooling device is provided on the battery box 1; the cooling device Comprising a water cooling system and an air cooling system, the air cooling system includes a ventilation fan 7 and a temperature controller 6, and the ventilation fan 7 is connected to a power supply through the temperature controller 6; the temperature controller 6 includes a metal casing 61, an input power supply Line 62, output power line 63, fixed beam 64, rotating beam 65, movable conductive groove 66, fixed conductive block 67, wax block 68, and the manufacturing materials of fixed beam 64, rotating beam 65 are insulating materials; A temperature inlet 611 is opened on the top wall of 61, and the inner wall of the temperature inlet 611 is bonded to the wax block 68 embedded in it, and the wax block 68 is...

Embodiment 2

[0032] Basic content is the same as embodiment 1, the difference is:

[0033] The side wall of the battery box 1 is provided with an air inlet 3 at the position on the back of the ventilation fan 7, and the side wall of the battery box 1 is provided with an air outlet 4 at a position facing the ventilation fan 7, and the air inlet 3, the air outlet 4 facing the setting. A plurality of cooling fins 21 are uniformly arranged on the top of the power battery 2 , and adjacent cooling fins 21 are arranged parallel to each other. The side wall and the bottom wall of the battery box 1 are covered with a heat insulation and noise reduction protective layer 11 , and the heat insulation and noise reduction protection layer 11 is connected to the battery box 1 by bonding.

Embodiment 3

[0035] Basic content is the same as embodiment 1, the difference is:

[0036] The water cooling system includes a water pump 5 and a water flow circuit 51 , the water pump 5 communicates with one end of the water flow circuit 51 , and the other end of the water flow circuit 51 meanders through the bottom of the power battery 2 and then communicates with the water pump 5 . The meandering manner of the water flow circuit 51 is a back shape, a serpentine shape or a zigzag shape.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap