Double-side staggered-tooth tau/2 low-thrust-ripple permanent magnet synchronous linear motor

A permanent magnet synchronous linear, low-thrust technology, applied in the direction of electrical components, electromechanical devices, propulsion systems, etc., can solve the problems of the average thrust of the motor, the increase of fluctuations, and the impact on the control accuracy of the linear motor system, so as to suppress thrust fluctuations, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

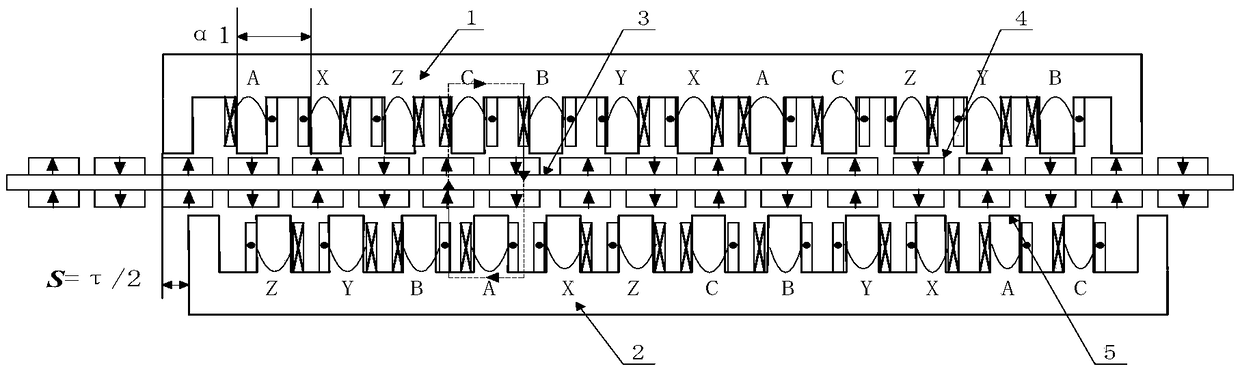

[0027] Such as Figure 1 to Figure 5 As shown, it is the first embodiment of the low-thrust fluctuation permanent magnet synchronous linear motor with bilateral staggered teeth τ / 2 of the present invention. The pole slots are matched with 14 poles and 12 slots. The motor includes a primary assembly 1 and a primary assembly 2 . and the secondary assembly 3, wherein the primary assembly 1 is composed of a core yoke 1-1, a core tooth 1-2 and an armature winding 1-3, and the core yoke 1-1 and the core tooth 1-2 form a slotted structure, and the electric The pivot winding 1-3 is wound on the tooth; the primary component 2 is composed of the core yoke 2-1, the core tooth 2-2 and the armature winding 2-3, and the core yoke 2-1 and the core tooth 2-2 form a slot structure , the armature winding 2-3 is wound on the teeth; the secondary assembly 3 is composed of a permanent magnet 3-1 and a yoke plate 3-2, each pair of poles includes four permanent magnets, and the permanent magnets loc...

Embodiment approach 2

[0033] Such as Figure 6 , 7 Shown in , 8 is the second embodiment of the low-thrust fluctuation permanent magnet synchronous linear motor with bilateral staggered teeth τ / 2 of the present invention, and its pole slots are matched with 10 poles and 12 slots.

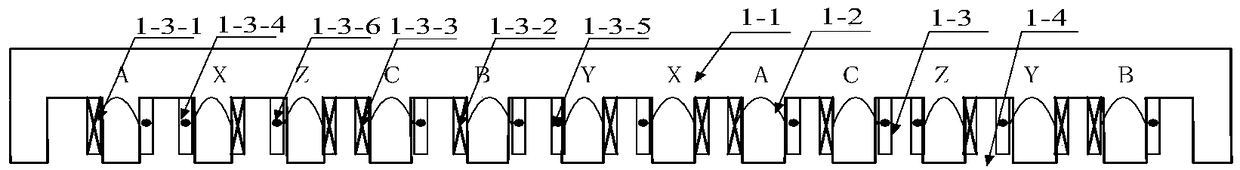

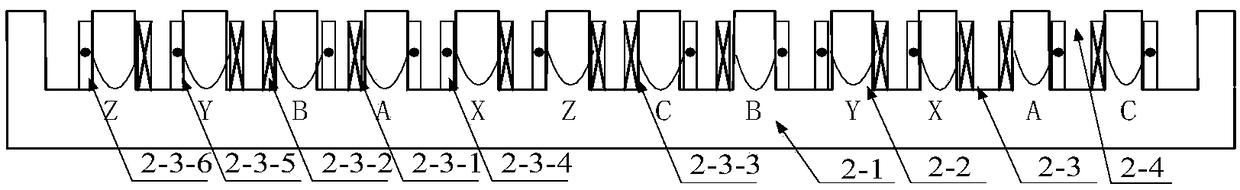

[0034] On the primary component 1, the A-phase winding 1-3-1 is set in the first slot and the third slot 1-4, the first slot is a half-filled slot, and the X-phase winding 1-3-4 is set in the In 2 slots; B-phase winding 1-3-2 is set in the 4th slot, Y-phase winding 1-3-5 is set in the 3rd and 5th slots; C-phase winding 1-3-3 Set in the 5th slot and the 7th slot, the Z-phase winding 1-3-6 is set in the 6th slot; the windings in the 1st-7th slot form a unit motor winding structure; the second unit motor The windings are arranged in the 7th to 13th slots, the phase sequence of the windings is exactly the same as that of the first unit motor, and the winding direction is completely opposite to that of the first unit motor....

Embodiment approach 3

[0037] Such as Figure 9, 10 Shown in , 11 is the third embodiment of the low-thrust fluctuation permanent magnet synchronous linear motor with bilateral staggered teeth τ / 2 of the present invention, and its pole slots are matched with 20 poles and 18 slots.

[0038] On the primary component 1, the A-phase winding 1-3-1 is set in the first slot and the third slot 1-4, the first slot is a half-filled slot, and the X-phase winding 1-3-4 is set in the 2 slots and the 4th slot; C-phase winding 1-3-3 is set in the 4th and 6th slot, Z-phase winding 1-3-6 is set in the 5th and 7th slot Inside; B-phase winding 1-3-2 is set in the 7th and 9th slots, Y-phase winding 1-3-5 is set in the 8th and 10th slots; 1st-10th The winding in the slot forms a unit motor winding structure; the winding of the second unit motor is set in the 10th to 19th slot, the phase sequence of the winding is exactly the same as that of the first unit motor, and the winding direction of the winding is the same as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com