A kind of compound dark tea processing method

A processing method and a composite technology, applied in the direction of tea treatment before extraction, can solve the problems of deep fermentation degree of dark tea and single flavor of tea leaves, and achieve the effect of bright orange-red soup color, rich layered taste, and unique and long-lasting aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

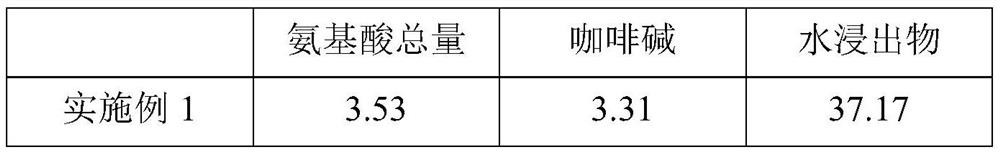

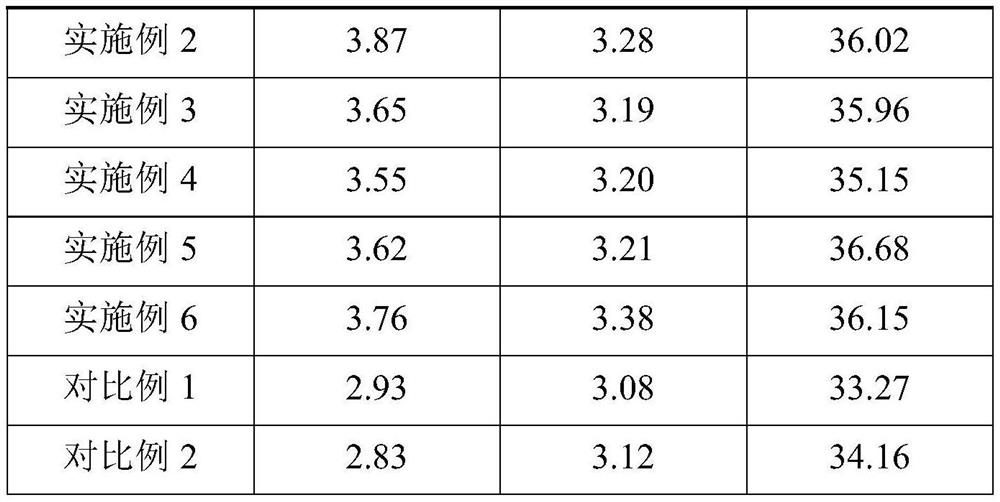

Examples

Embodiment 1

[0051] Compound dark tea

[0052] (1) Raw material preparation: select the newly processed finished raw tea as raw material, take 60% of black tea (including black tea) and 40% of raw tea (including black tea) according to weight percentage, and mix them as raw materials, and the moisture content of raw tea is 13%.

[0053] (2) Mixed frying: use a bottle-type tea frying machine to soften, put the leaves into the pot at a temperature of 200°C, add 14kg of water for every 100kg of tea, fry for 8 minutes, and control the leaf temperature at 60±2°C; after frying, the leaf quality is evenly moist and soft.

[0054] (3) Heap fermentation: ferment the tea leaves while they are hot, with a heap height of 1 ± 0.2 meters, an indoor temperature of 27 ± 3°C, and a humidity of 75% ± 10%. Ferment for 72 hours.

[0055] (4) Drying: After the pile fermentation is completed, the pile fermented (tea) leaves are carried out with a bottle-type tea frying machine, about 150 catties per pot, the ...

Embodiment 2

[0058] Compound dark tea

[0059] (1) Raw material preparation: select the newly processed finished raw tea as raw material, take black mao tea (including black tea) 90% + white mao tea (including black tea) 10% according to weight percentage, mix as raw material, and the moisture content of raw tea is 14%.

[0060] (2) Mixed frying: use a bottle-type tea frying machine to soften, put the leaves into the pot at a temperature of 200°C, add 10kg of water for every 100kg of tea, fry for 5 minutes, and control the leaf temperature at 60±2°C; after frying, the leaf quality is evenly moist and soft.

[0061] (3) Heap fermentation: ferment the tea leaves while they are hot, with a heap height of 1±0.2m, indoor temperature of 26±1°C, humidity of 75%±15, and fermentation for 120 hours.

[0062] (4) Drying: use a bottle-type tea frying machine, pile 100 catties of fermented leaves in each pot, import the pot temperature at 185°C, and leave the pot at a temperature of 55±2°C, add water ...

Embodiment 3

[0065] Compound dark tea

[0066] (1) Raw material preparation: select the newly processed finished mao tea as raw material, take black mao tea (containing black tea) 70%+green mao tea (containing oolong tea) 30% according to weight percentage, mix as raw material.

[0067] (2) Mixing and frying: Mix the above tea leaves and use a bottle-type tea frying machine to soften them. The temperature of the leaf inlet pot is 200°C, add 30kg of water for every 100kg of tea, and fry for 10 minutes. The leaf temperature is controlled at 60±2°C; the leaves after frying The texture is evenly watery and soft.

[0068] (3) Heap fermentation: ferment the tea leaves while they are hot, the height of the heap is 0.95-1.1 meters, the indoor temperature is 27±5℃, the humidity is 75%±10%, and it is fermented for 48 hours.

[0069] (4) Drying: Use a bottle-type tea frying machine. Each pot contains 300 catties of fermented leaves. The temperature of the imported pot is 190°C.

[0070] (5) Aging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com