Medical laser thermal therapy target head based on graphite-based composite thermal conductive material

A composite heat-conducting material and graphite-based technology, applied in the field of laser hyperthermia target head and medical laser hyperthermia target head, can solve the problems of unfavorable wound wound area, easy burning of the optical fiber head, high treatment risk, etc., so as to improve the continuous heat conduction. effect, prevention of overheating and even burns, effect of reducing the risk of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

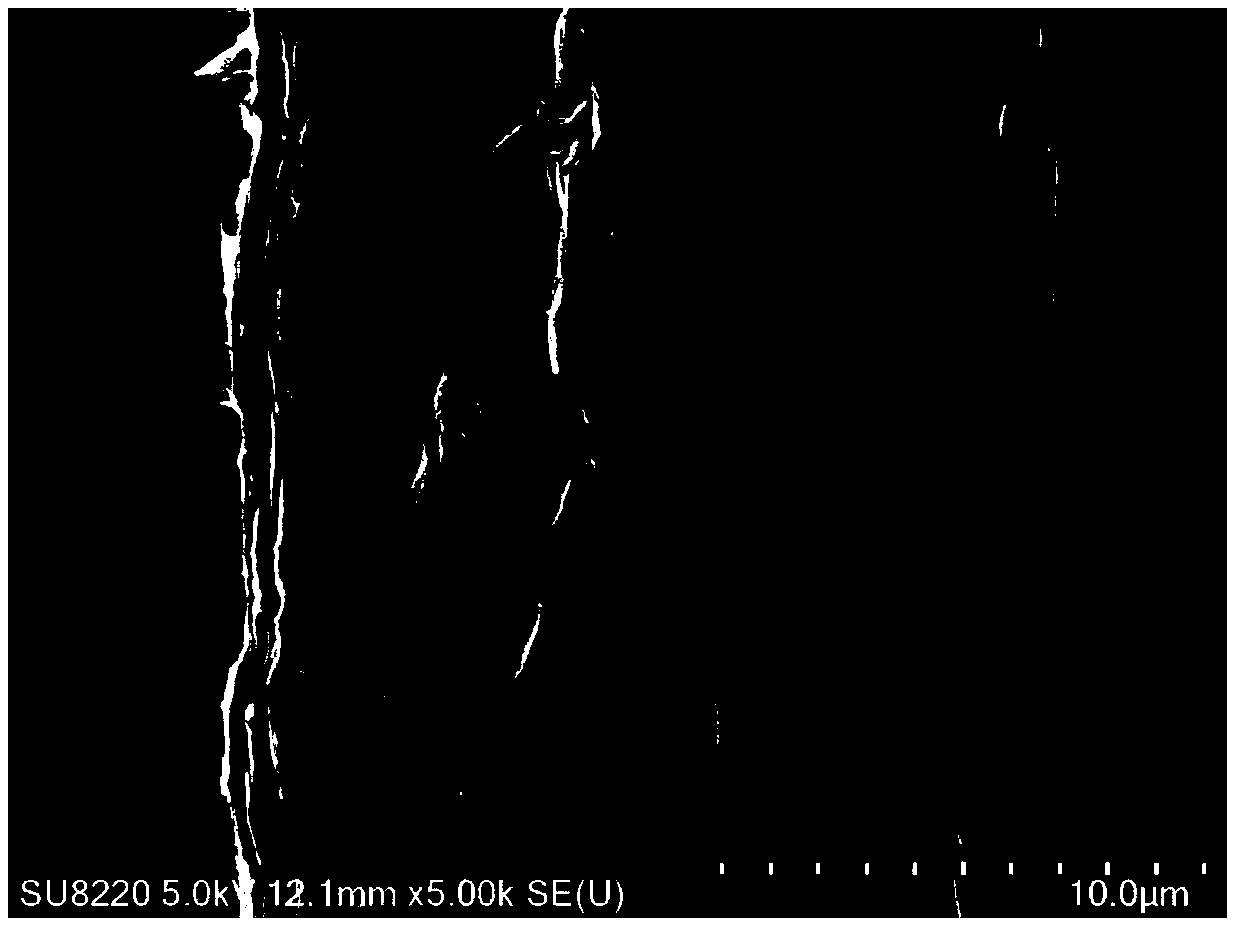

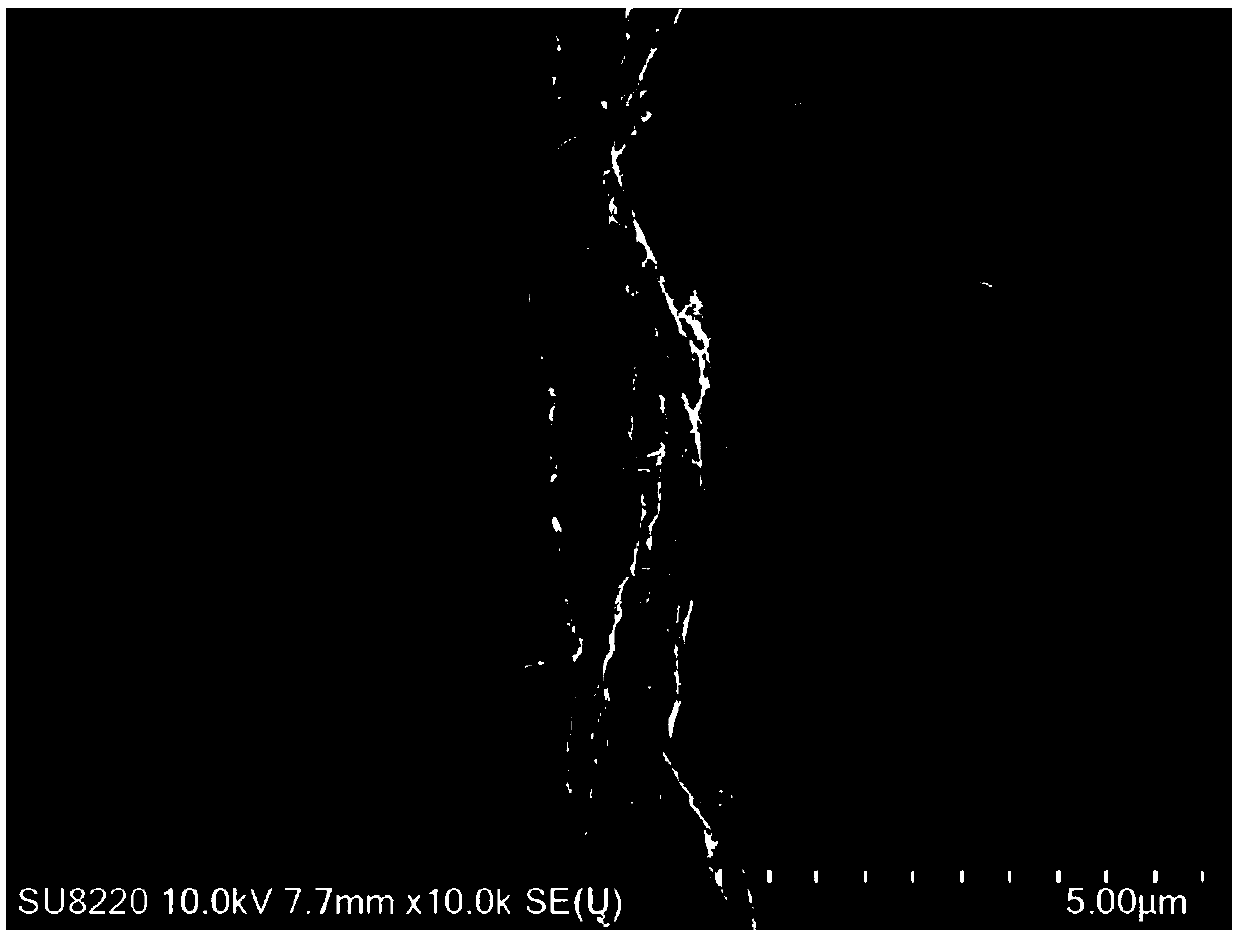

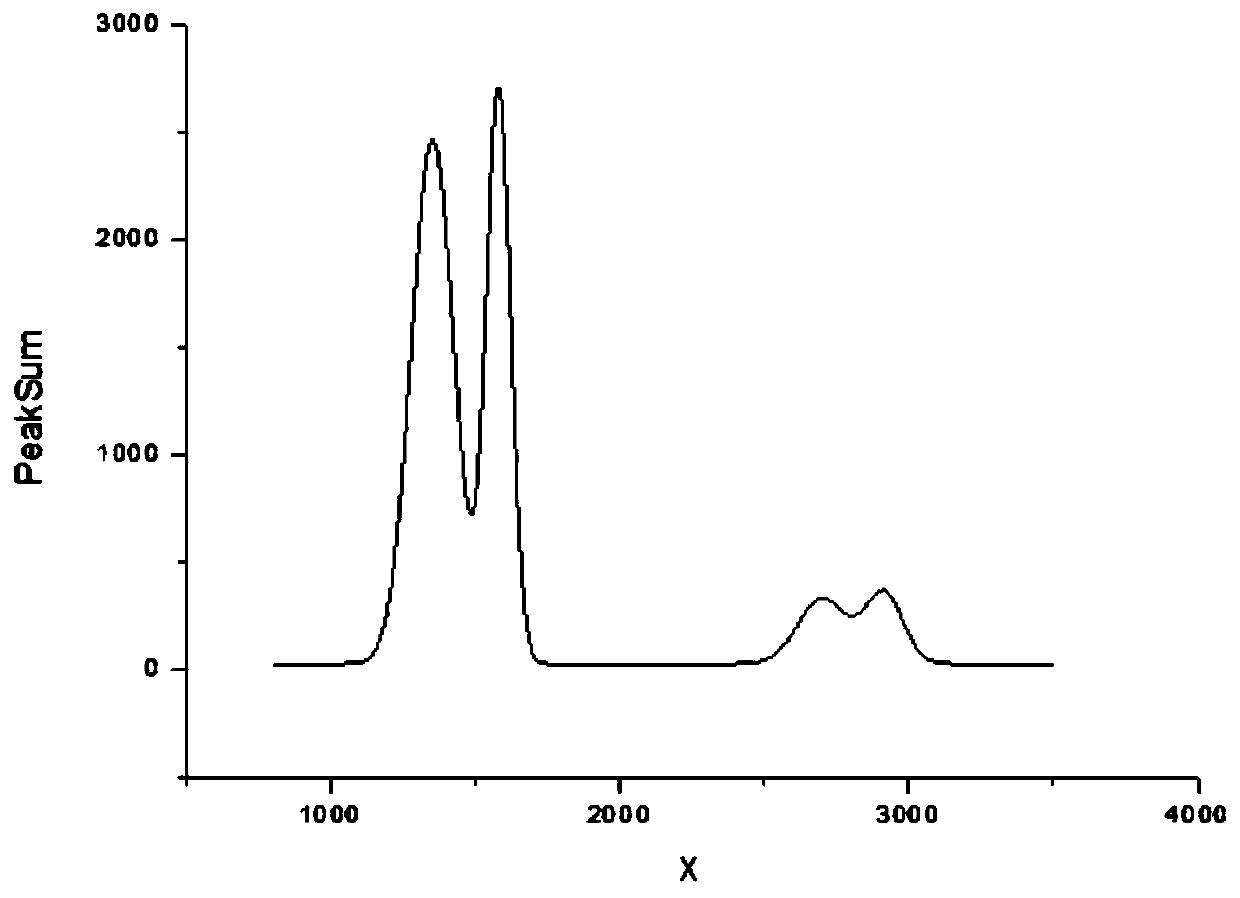

Image

Examples

Embodiment 1

[0045] A graphite-based composite heat-conducting material, made of the following components by weight: 80 parts of graphene oxide (concentration 4mg / ml), 20 parts of filler solution (solute is chromium formate, solvent is carbon tetrachloride, wherein , the mass ratio of chromium formate to carbon tetrachloride is 1:15).

[0046] A preparation method based on graphite-based composite heat-conducting material, comprising the following steps:

[0047] 1) Add 6ml of graphene oxide solution dropwise to a suction filter funnel and filter for 2 hours to obtain a graphene oxide film, and place the graphene oxide film in a vacuum oven at 70°C for 2 hours to dry.

[0048] 2) The dried graphene oxide film is completely immersed in the filler solution for 1 hour, taken out, and dried in a vacuum oven at 50° C. for 4 hours to obtain a modified graphite sheet.

[0049] 3) Sandwich the modified graphite sheet between two smooth and flat graphite plates, apply a pressure of 10MPa and place...

Embodiment 2

[0060] A graphite-based composite heat-conducting material, made of the following components by weight: 75 parts of graphene oxide (concentration 4mg / ml), 25 parts of filler solution (solute is chromium formate, solvent is carbon tetrachloride, wherein , the mass ratio of chromium formate to carbon tetrachloride is 1:10).

[0061] A preparation method based on graphite-based composite heat-conducting material, comprising the following steps:

[0062] 1) Add 8ml of graphene oxide solution dropwise to a suction filter funnel and filter for 2 hours to obtain a graphene oxide film, and place the graphene oxide film in a vacuum oven at 60°C for 2 hours to dry.

[0063] 2) The dried graphene oxide film was completely immersed in the filler solution for 2 hours, taken out, and dried in a vacuum oven at 40°C for 3 hours to obtain a modified graphite sheet.

[0064] 3) Sandwich the modified graphite sheet between two smooth and flat graphite plates, apply a pressure of 10 MPa and plac...

Embodiment 3

[0070] A graphite-based composite heat-conducting material, made of the following components by weight: 70 parts of graphene oxide (concentration 6mg / ml), 30 parts of filler solution (solute is chromium formate, solvent is carbon tetrachloride, wherein , the mass ratio of chromium formate to carbon tetrachloride is 1:20).

[0071] A preparation method based on graphite-based composite heat-conducting material, comprising the following steps:

[0072] 1) Add 6ml of the graphene oxide solution dropwise into a suction filter funnel and filter for 2 hours to obtain a graphene oxide film, and dry the graphene oxide film in a vacuum oven at 50°C for 3 hours.

[0073] 2) The dried graphene oxide film was completely immersed in the filler solution for 2 hours, taken out, and dried in a vacuum oven at 50° C. for 4 hours to obtain a modified graphite sheet.

[0074] 3) Sandwich the modified graphite sheet between two smooth and flat graphite plates, apply a pressure of 10 MPa and place...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com