Cleaning and disinfecting method for pasteurized milk recovered glass bottles

A technology for cleaning and sterilizing glass bottles, which is applied in the directions of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc. The effect of low blast rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

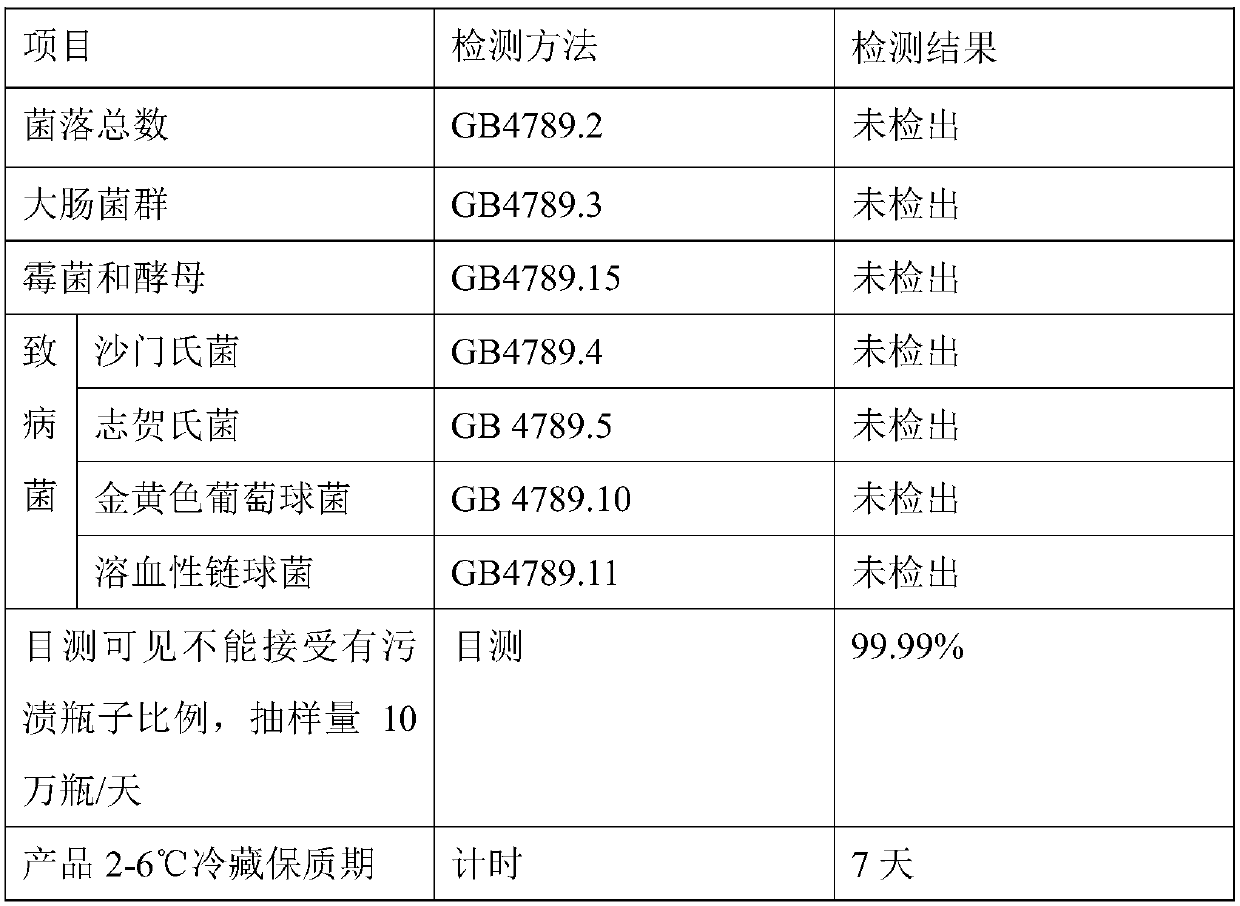

[0059]The specifications of pasteurized milk glass bottles are shown in Table 1.

[0060] Table 1 Specifications of Glass Bottles

[0061] project

index

Mouth capacity, mL

200±8

Empty bottle weight, g

220±5

bottle height, mm

129.5±1.2

33±1

57.5±1.2

Bottle wall thickness, mm, ≥

2.0

Bottom thickness, mm, ≥

3.0

[0062] The whole process of pasteurized milk glass bottle cleaning and disinfection process should include recycling glass bottle picking, pre-washing, 1# lye soaking, 1# brush cleaning, 2# lye soaking, 2# brush cleaning, 3# brush cleaning, Clean water washing, disinfection water disinfection process and other operations. The whole process of the process of cleaning and disinfecting the pasteurized glass milk bottle of the present invention is as follows:

[0063] 1) Sorting of recycled glass bottles: Remove foreign objects and cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com