Experimental device for improving yield of nano-particles prepared by metal wire electrical explosion

A nanoparticle and experimental device technology, applied in nanotechnology and other directions, can solve the problems of increasing production investment time and equipment costs, restricting the production and generation efficiency of nanoparticles, inconvenient operation and use, etc. The effect of energy utilization and reduction in the scale of production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Nanoparticles of metal aluminum and copper have important application value in many fields due to their high specific surface area, high oxidation energy release rate, quantum size effect, high thermal conductivity, low resistance and efficient catalytic activity.

[0044] In the process of preparing nanoparticles by electric explosion of aluminum or copper wire, the inert gas argon is generally used as the protective gas, and the pressure is between 1.0 and 3.0 bar. An electric explosion occurs.

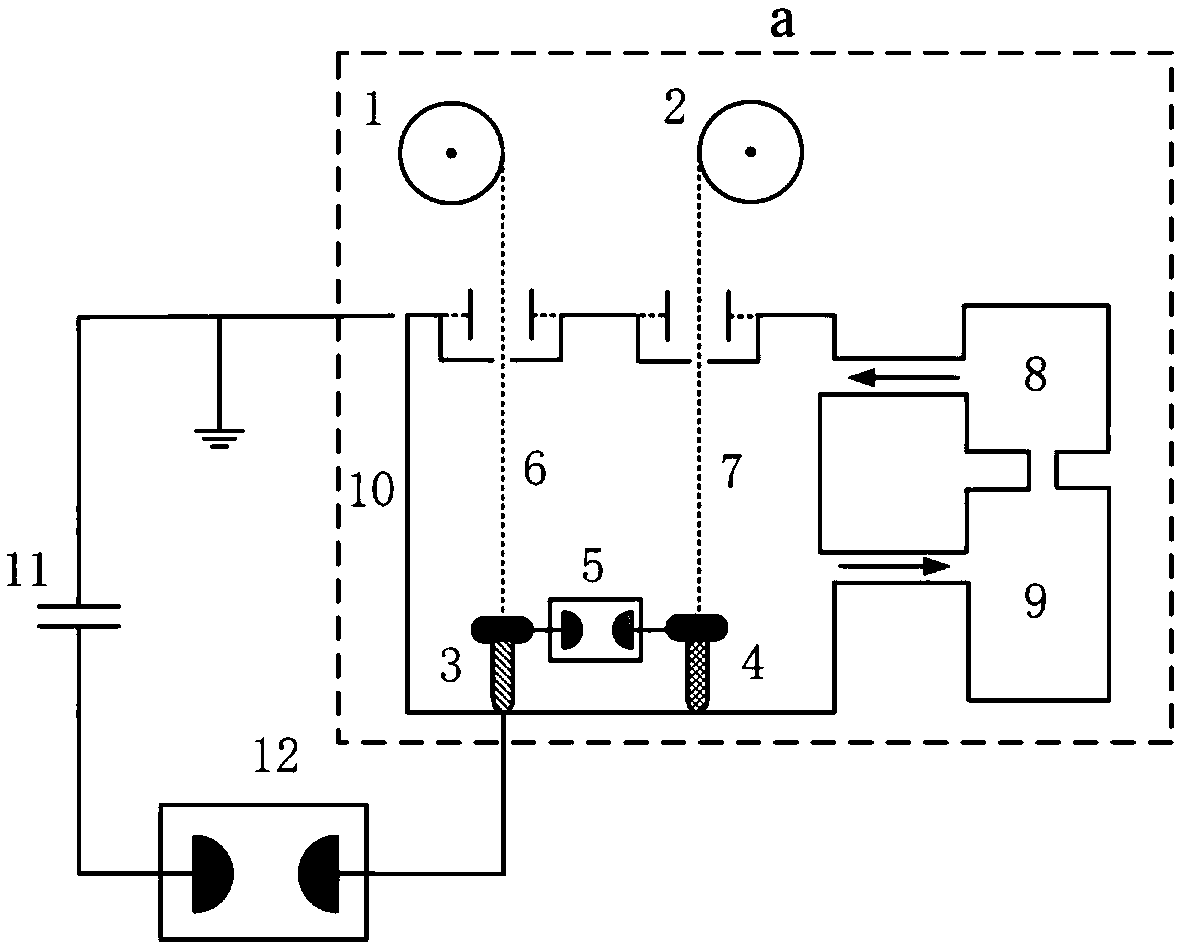

[0045] The capacity of the high-voltage pulse capacitor 11 is between 0.1-10.0 μF, the voltage is between 10-50 kV, and the electric explosion of a single aluminum wire is formed by the current pulse drive with a pulse of microsecond level by discharge. In order to increase the unit yield of nanoparticles, the device of the present invention can be used to improve the efficiency of electric explosion of metal wire, appropriately increase the capacitance, and adjust the curren...

Embodiment 2

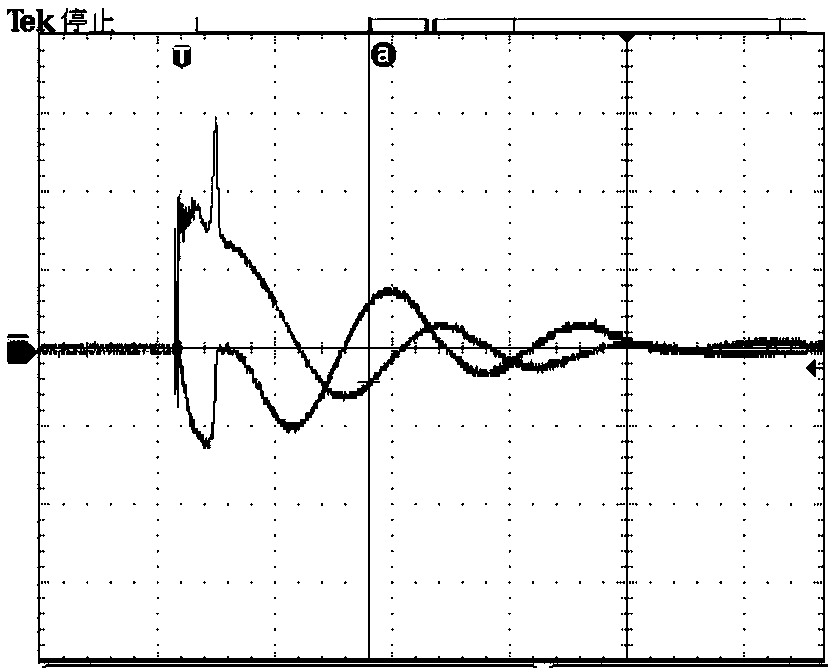

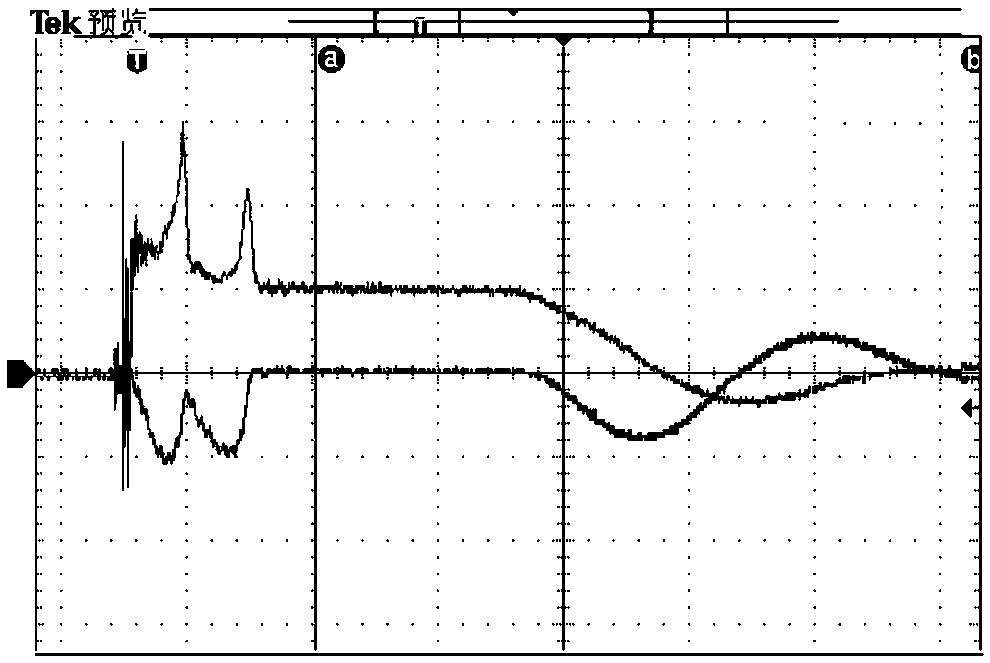

[0048] During the preparation of metal aluminum and copper nanoparticles, the metal wire needs to be vaporized at a certain heating rate, which makes the explosion process of the metal wire often appear in the later stage of the rapid rise of the current, and then the energy stored in the pulse capacitor is very important for the formation of more nano particles. Particles are not contributing.

[0049] In order to improve the output of nanoparticles, the device of the present invention can be used to improve the electric explosion efficiency of the metal wire. After the first metal wire explodes, the energy in the pulse capacitor is transferred to the second metal wire, and the length of the second metal wire is adjusted so that The parameters of the electric explosion process are the same as those of the first metal wire. According to the length of the first metal wire, the length of the second metal wire can be 0.6-0.9 times the length of the first metal wire. This can ensu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com