Composite packaging film for glossy laser cigarettes and preparation method thereof

A composite packaging film and laser technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of heat-sealing performance degradation, easy to fall off, unclear patterns, etc., to reduce the heat-sealing initiation temperature and reduce energy consumption , to avoid the effect of scratching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

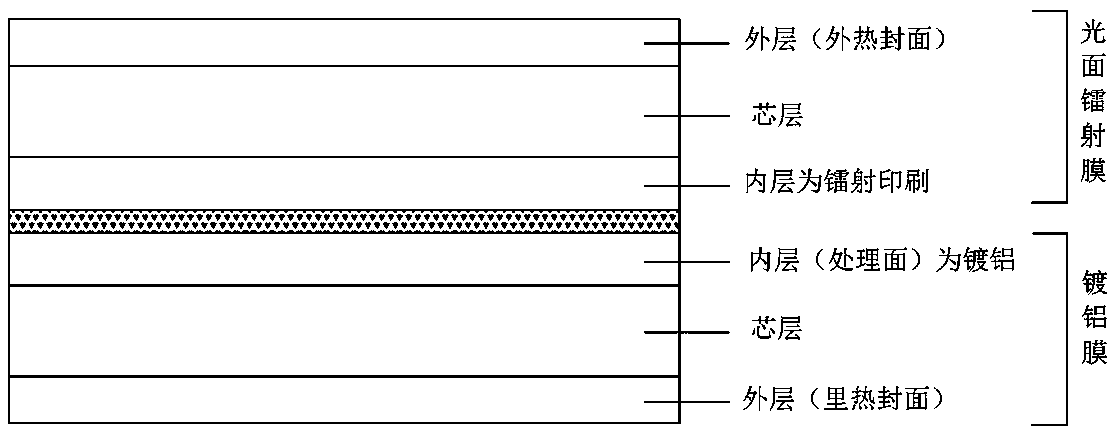

Image

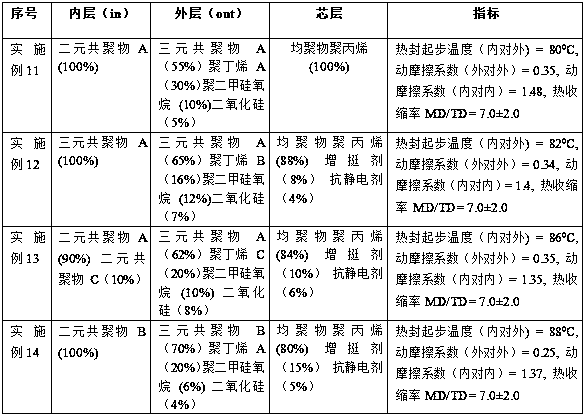

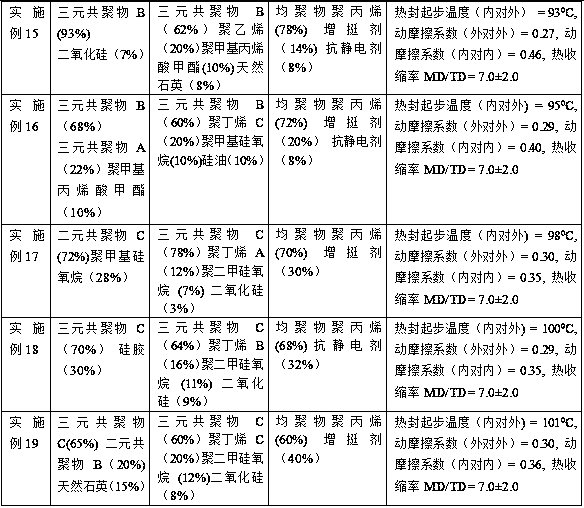

Examples

preparation example Construction

[0029] The preparation method of the composite packaging film for smooth laser cigarettes of the present invention comprises the following steps:

[0030] A. Preparation of glossy substrate film: The multi-layer co-extrusion polypropylene biaxial stretching preparation process and polypropylene film are used for preparation, wherein the longitudinal stretching temperature is 70-130°C, and the transverse stretching temperature is 100-175°C. The temperature of the extruder is 200-250°C, and the draw ratio is 4-10;

[0031] B. Laser embossing process: laser pattern embossing is carried out on the B layer of the base film by using laser molding process; the main process of laser molding described above: electroforming plate-making-unwinding-preheating-molding-cooling- Winding;

[0032] C. Ink printing: After the laser imprinting is completed, the surface polarity treatment is carried out first, and then ink printing is carried out on the laser surface, using environmentally frien...

Embodiment 20

[0043] The preparation method of the composite packaging film for smooth laser cigarettes as in the above embodiment 1 comprises the following steps:

[0044] A. Preparation of glossy substrate film: The multi-layer co-extrusion polypropylene biaxial stretching preparation process and polypropylene film are used for preparation, wherein the longitudinal stretching temperature is 70°C, the transverse stretching temperature is 100°C, and the extruder temperature is 200°C, and the draw ratio is 4;

[0045]B. Laser embossing process: laser pattern embossing is carried out on the B layer (inner layer) of the substrate film by laser molding process; Molding - cooling - winding;

[0046] C. Ink printing: After the laser imprinting is completed, the surface polarity treatment is carried out first, and then ink printing is carried out on the laser surface, using environmentally friendly water-based ink, and the printing is completed through the gravure printing process. The main proc...

Embodiment 21

[0049] Select a solvent-free polyurethane adhesive as an adhesive to carry out composite processing on the laser printing packaging film obtained in Example 2 and the aluminized packaging film obtained in Example 11, and obtain the composite packaging film. The preparation method comprises the following steps:

[0050] A. Preparation of glossy substrate film: It is prepared by multi-layer co-extrusion polypropylene biaxial stretching preparation process and polypropylene film, wherein the longitudinal stretching temperature is 130°C, the transverse stretching temperature is 175°C, and the extruder temperature is 250°C, and the draw ratio is 10;

[0051] B. Laser embossing process: use laser molding process to emboss the laser pattern on the B layer of the base film; the laser molding process described: electroforming plate-unwinding-preheating-molding-cooling-receiving roll;

[0052] C. Ink printing: After the laser embossing is completed, the surface polarity treatment is ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com