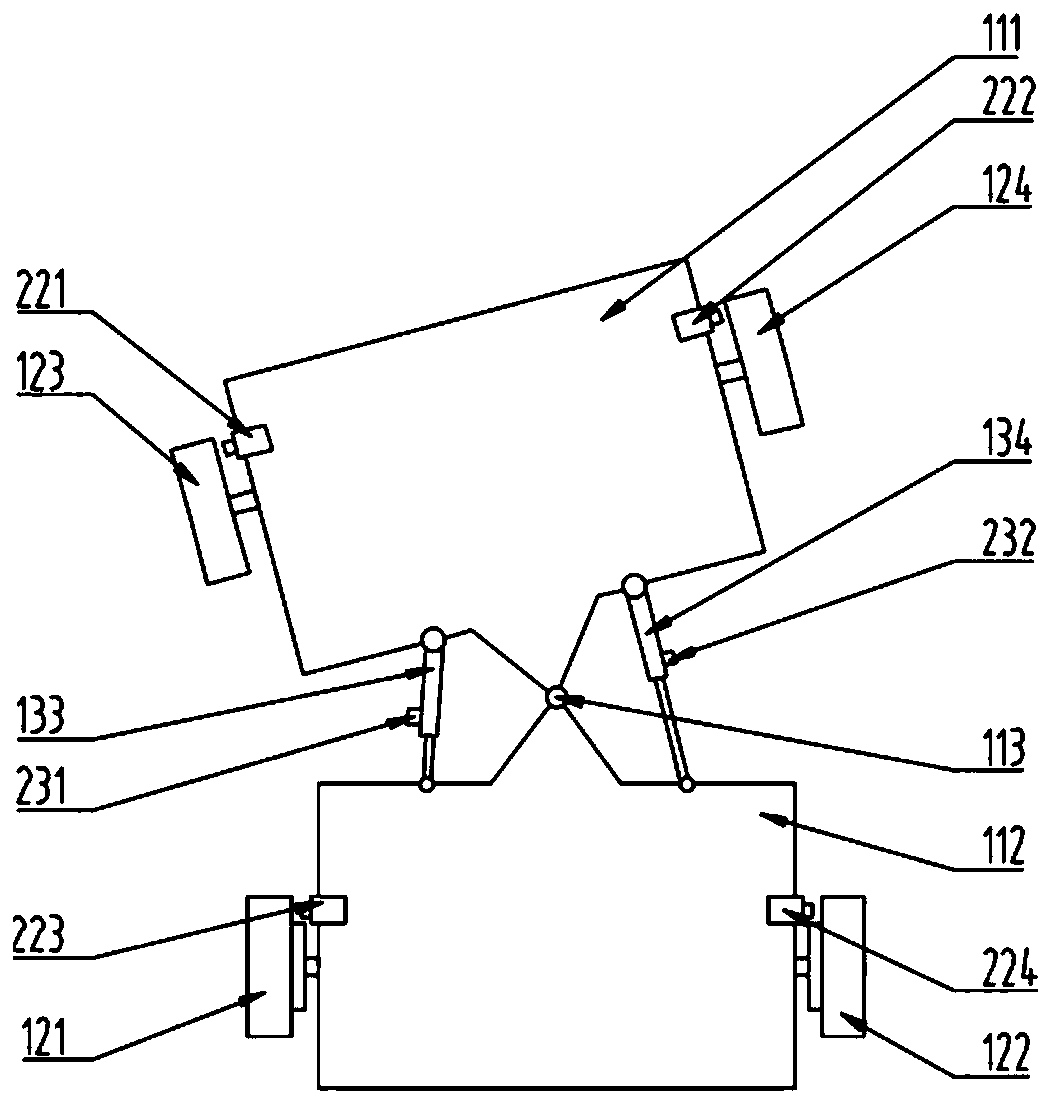

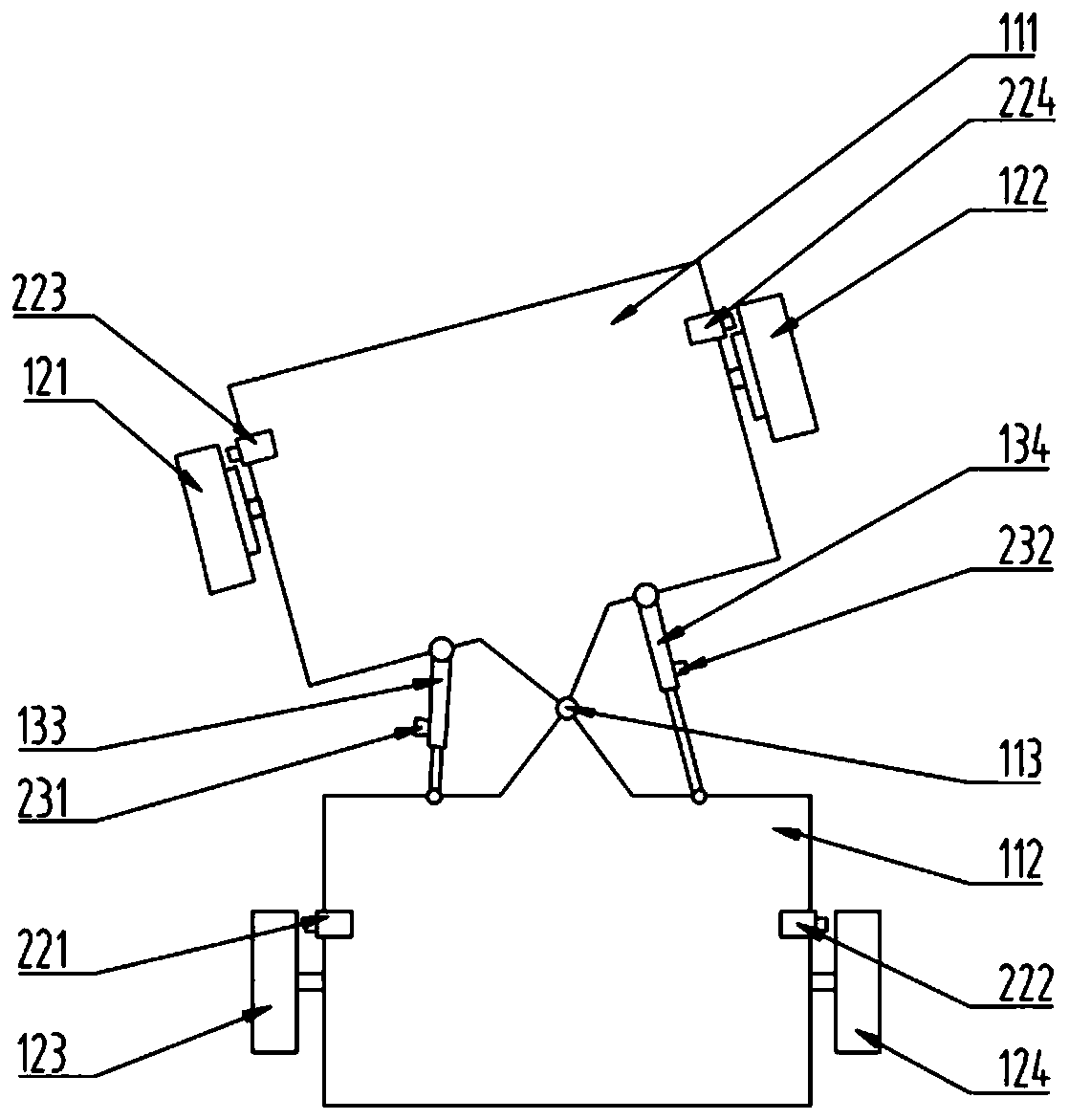

Differential cooperative steering system and control method for articulated steering vehicle with single-axis independent drive

An independent drive and steering system technology, applied to vehicle components, steering mechanisms, fluid steering mechanisms, etc., can solve the problems of increasing vehicle reactive power loss, increasing vehicle drive power consumption, reducing vehicle speed, etc., to reduce energy consumption, reduce Effects of energy consumption and reduced turning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

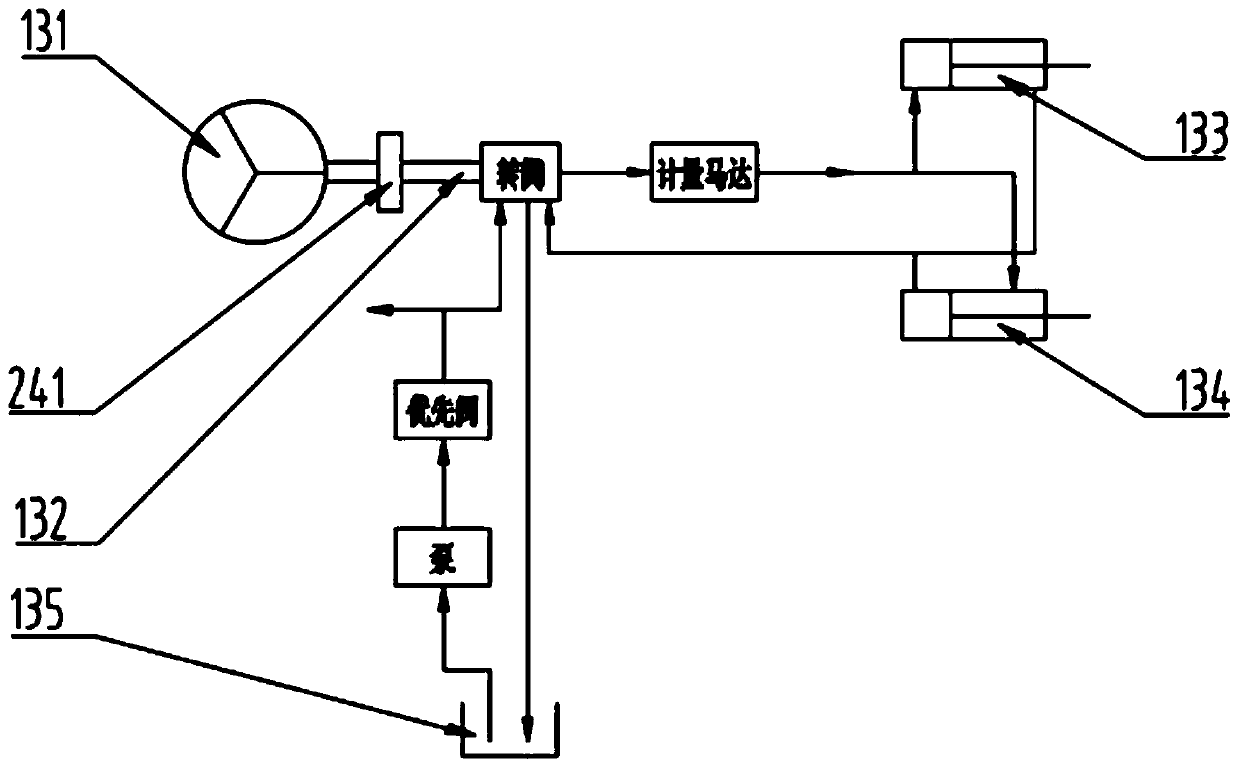

Method used

Image

Examples

Embodiment 1

[0064] like Image 6 As shown, when the control method of the differential cooperative steering system of a single-axle independent drive articulated steering vehicle according to the present invention is applied to an articulated steer vehicle with an independent rear axle drive, the control process is specifically as follows:

[0065] Step 1. After power on, initialize the differential cooperative steering controller, complete the self-inspection process, and read the control parameters stored in the single-chip microcomputer of model MC9S12x, mainly including:

[0066] 1. Control threshold: vehicle speed threshold V 0 (km / h); left and right hydraulic cylinder displacement threshold X l0 、X r0 (mm); Steering wheel angle threshold ε 1 (°); Steering wheel angular velocity threshold ε 2 (° / s); inner drive wheel slip rate threshold s i0 ;

[0067] 2. The enabling state parameter ipb of the differential cooperative steering system: after the vehicle is re-ignited and the di...

Embodiment 2

[0090] like Figure 7 As shown, when the control method of the differential cooperative steering system of a single-axle independently driven articulated steering vehicle according to the present invention is applied to an articulated steered vehicle with an independently driven front axle, the control process is specifically as follows:

[0091] Step 1. After power on, initialize the differential cooperative steering controller, complete the self-inspection process, and read the control parameters stored in the single-chip microcomputer of model MC9S12x, mainly including:

[0092] 1. Control threshold: vehicle speed threshold V 0 (km / h); left and right hydraulic cylinder displacement threshold X l0 、X r0 (mm); Steering wheel angle threshold ε 1 (°); Steering wheel angular velocity threshold ε 2 (° / s); outer drive wheel slip rate threshold s o0 ;

[0093] 2. The enabling state parameter ipb of the differential cooperative steering system: after the vehicle is re-ignited ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com