An integrated additive repair and remanufacturing method of EDM deposition-remelting and rolling

A technology of EDM deposition and remanufacturing, which is applied in the direction of metal material coating process, coating, etc., can solve the problems that affect the development and application of EDM deposition technology, the quality is difficult to control, and the deposition efficiency is low, so as to achieve excellent processing surface and eliminate Protruding parts on the surface, the effect of improving the surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

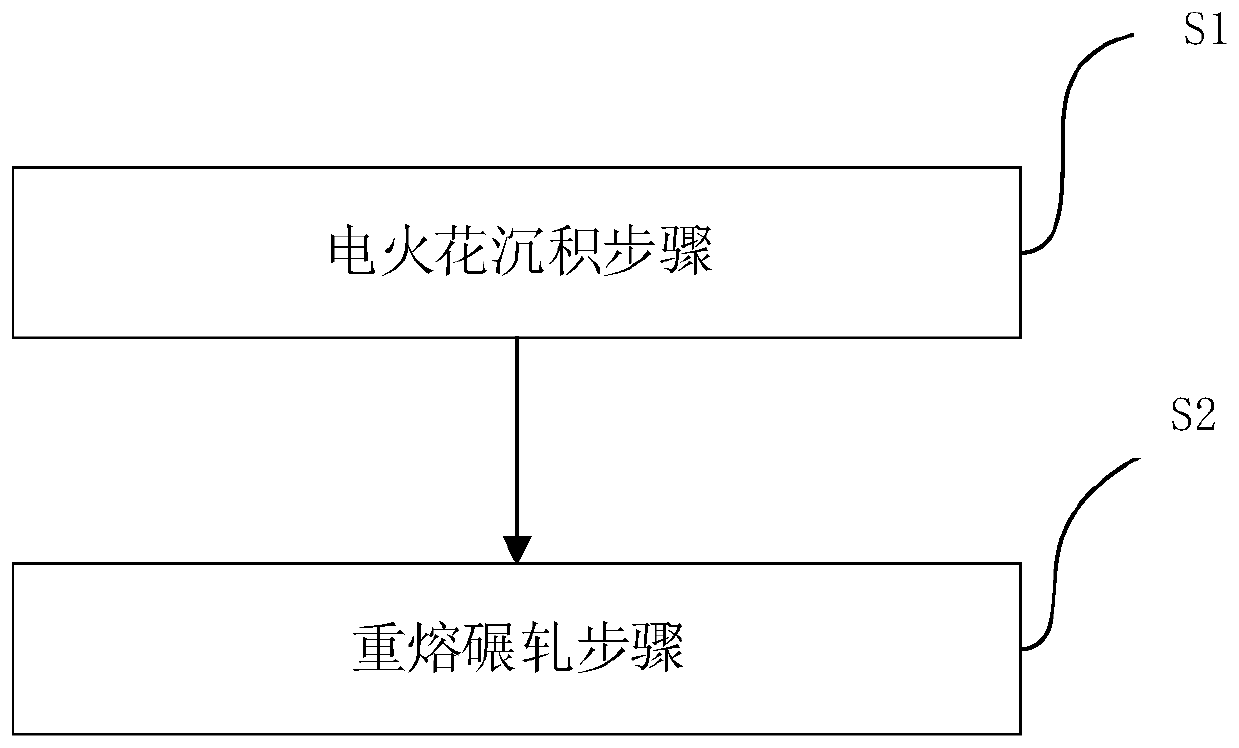

[0027] An integrated additive repair and remanufacturing method of electric spark deposition-remelting and rolling for rotating cluster electrodes, comprising the following steps:

[0028] First, place the part in the fixed cluster electrode EDM system and connect the power supply between the cluster electrode and the surface of the part;

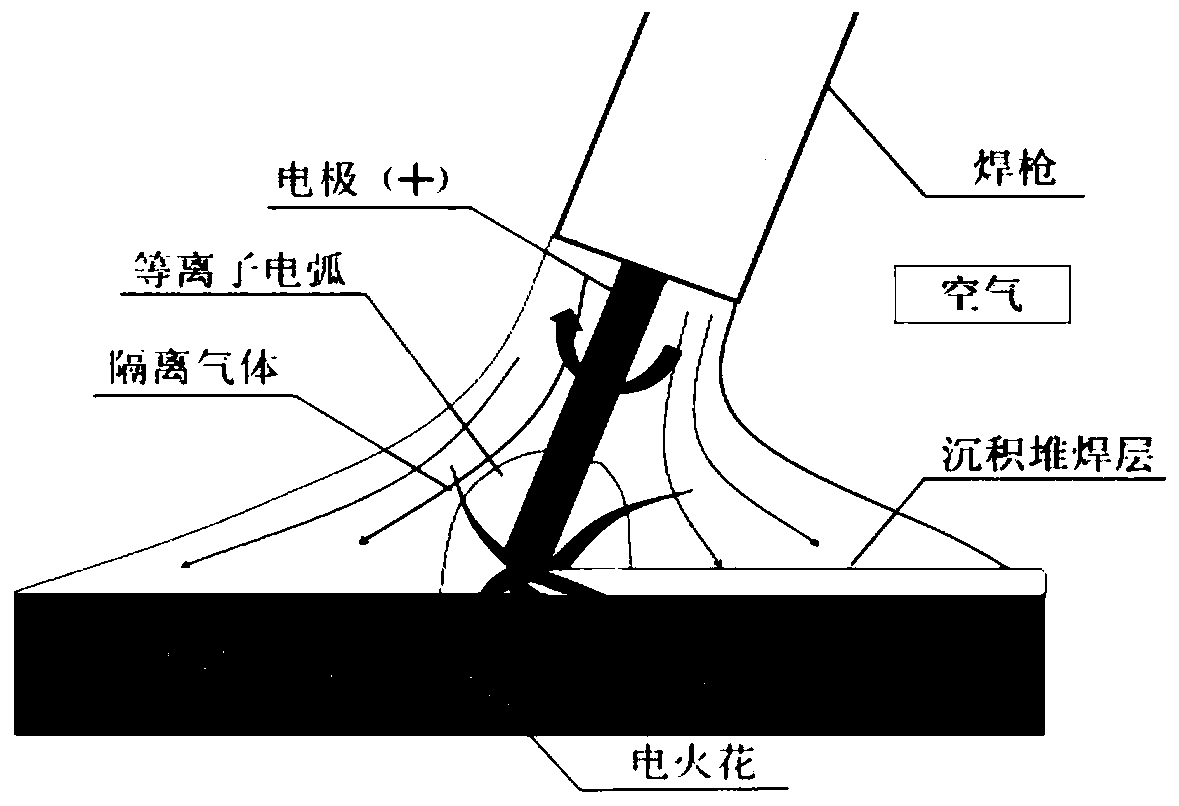

[0029] Secondly, conduct discharge deposition: in a protective atmosphere (such as argon), a breakdown discharge is generated between the two electrodes, and the cluster electrodes and part materials in the discharge area are heated and melted, and melted and melted under the action of electromagnetic force, centrifugal force, gravity, etc. The cluster electrode material is transitionally deposited on the surface of the part, and metallurgically combined with the surface material of the part to form an alloy layer;

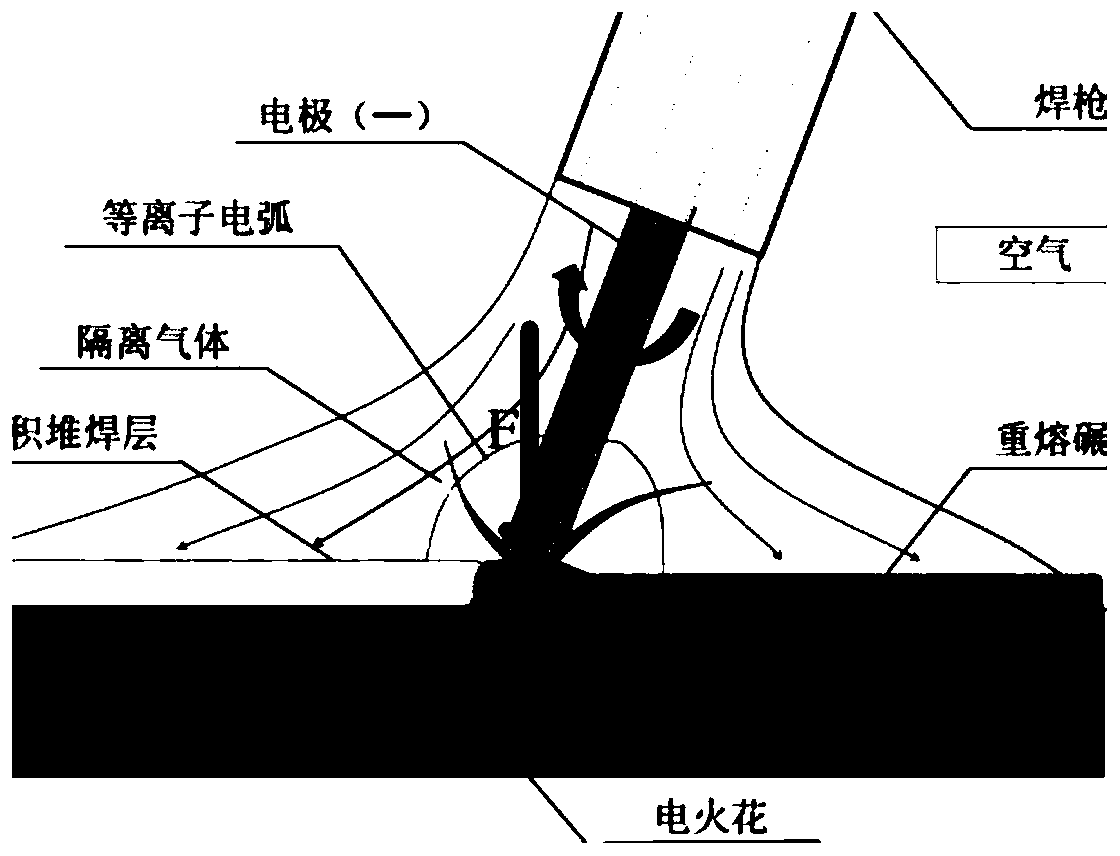

[0030] Third, carry out remelting and rolling of the deposited layer: through the method of exchanging the processing polarit...

Embodiment 2

[0033] An integrated additive repair and remanufacturing method of electric spark deposition-remelting and rolling for fixed parts with fixed cluster electrodes, comprising the following steps:

[0034] First, place the part in the fixed cluster electrode EDM system and connect the power supply between the cluster electrode and the surface of the part;

[0035] Secondly, carry out discharge deposition: in a protective atmosphere (such as argon), accurately control the distance between the two poles to generate a breakdown discharge between the two poles, heat and melt the cluster electrodes and part materials in the discharge area, under electromagnetic force, centrifugal force, gravity, etc. Under the action of the melting and melting cluster electrode material transition deposition to the surface of the part, and metallurgically bonded with the surface material of the part to form an alloy layer;

[0036] Thirdly, carry out remelting and rolling of the deposited layer. Under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com