A Viscoelastic Foam Flooding Method for Developing Deep Heavy Oil Reservoirs

A heavy oil reservoir and foam flooding technology, which is applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problem that deep heavy oil reservoirs cannot be developed by steam huff and puff and cannot be developed with deep heavy oil reservoirs. , wellbore, increased formation heat loss, etc., to improve the development effect, slow down the phenomenon of gas channeling, slow down the effect of rapid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

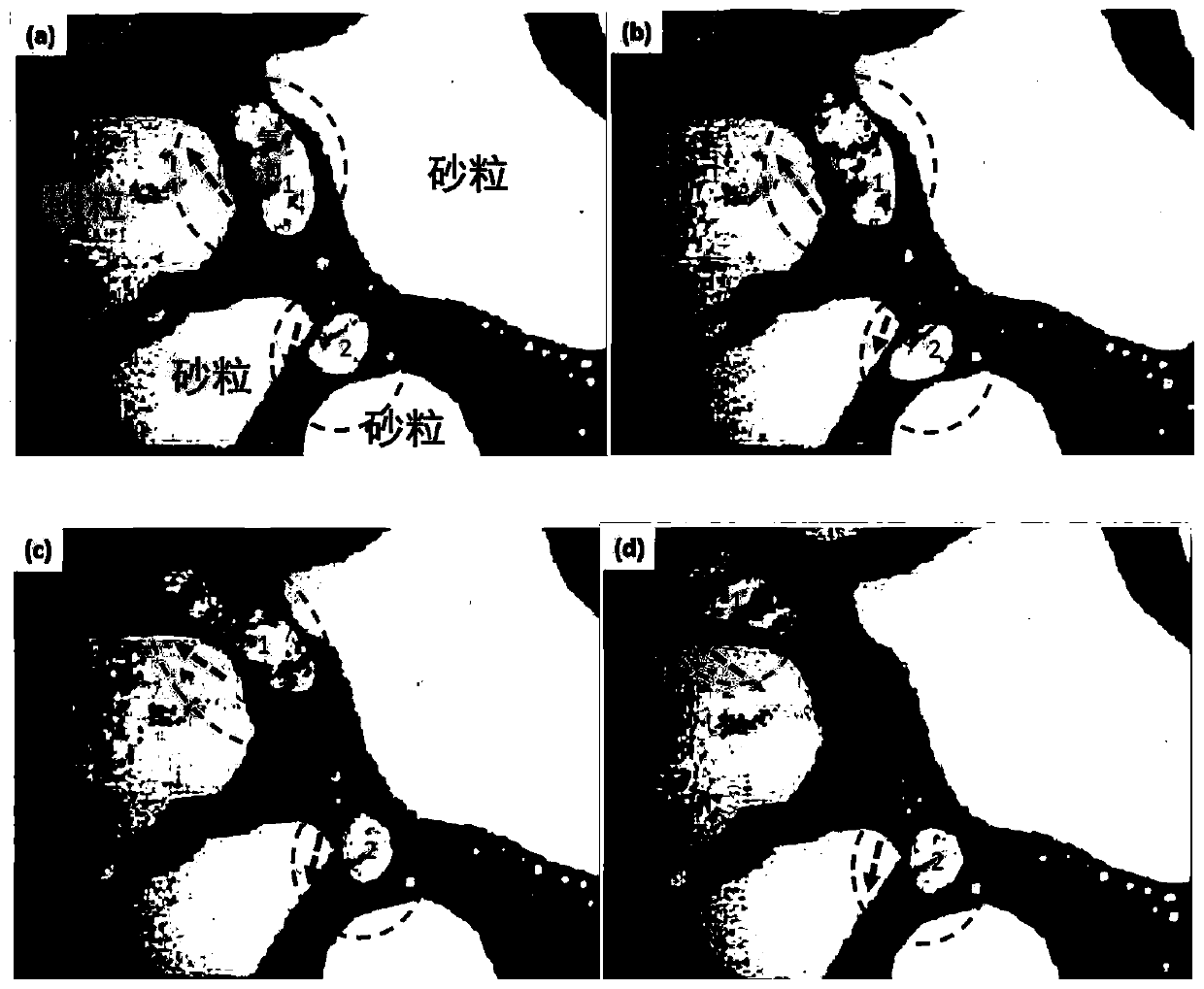

Image

Examples

Embodiment 1

[0039] The buried depth of a deep heavy oil reservoir is 1850m, the viscosity of ground degassed crude oil is 3141mPa.s, the total content of colloid and asphaltene in the crude oil is 8.5%, the initial oil saturation is 0.65, the thickness of the reservoir is 22m, and the horizontal permeability is 1880mD, vertical permeability of 240mD, and reservoir porosity of 0.35. The deep heavy oil reservoir was developed with steam huff and puff in the early stage, with 2000t of steam injected, and production started after 5 days of simmering the well, but the cycle output was only 25t. The oil output is too low, so thermal development methods such as steam huff and puff are not suitable for this deep heavy oil reservoir.

[0040] The viscoelastic foam flooding development method proposed by the present invention is implemented in this deep heavy oil reservoir.

[0041] (1) First, a five-point well pattern is established in the reservoir. The middle vertical well is an injection well, and t...

Embodiment 2

[0050] The buried depth of a deep heavy oil reservoir is 1779m, the viscosity of ground degassed crude oil is 2569mPa.s, the total content of colloid and asphaltene in the crude oil is 9.1%, the initial oil saturation is 0.61, the thickness of the reservoir is 19m, and the horizontal permeability is It is 1720mD, the vertical permeability is 314mD, and the porosity of the reservoir is 0.41. The deep heavy oil reservoir was developed with steam huff and puff in the early stage. The steam injection volume was 1900t, and the production started 5 days after simmering the well. However, the periodic oil output was only 21t and the oil output was too low. Therefore, steam huff and puff and other thermal recovery development The method is not suitable for this deep heavy oil reservoir.

[0051] The viscoelastic foam flooding development method proposed by the present invention is implemented in this deep heavy oil reservoir.

[0052] (1) First, a five-point well pattern is established in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com