On-load voltage regulating oil quality online monitoring apparatus

A monitoring device and quality technology, applied in the direction of measuring device, sampling device, material inspection product, etc., can solve the problems of inaccurate detection results, uneven sampling of pressure regulating oil by the detection device, backlog of impurities, etc., so as to avoid inaccurate detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

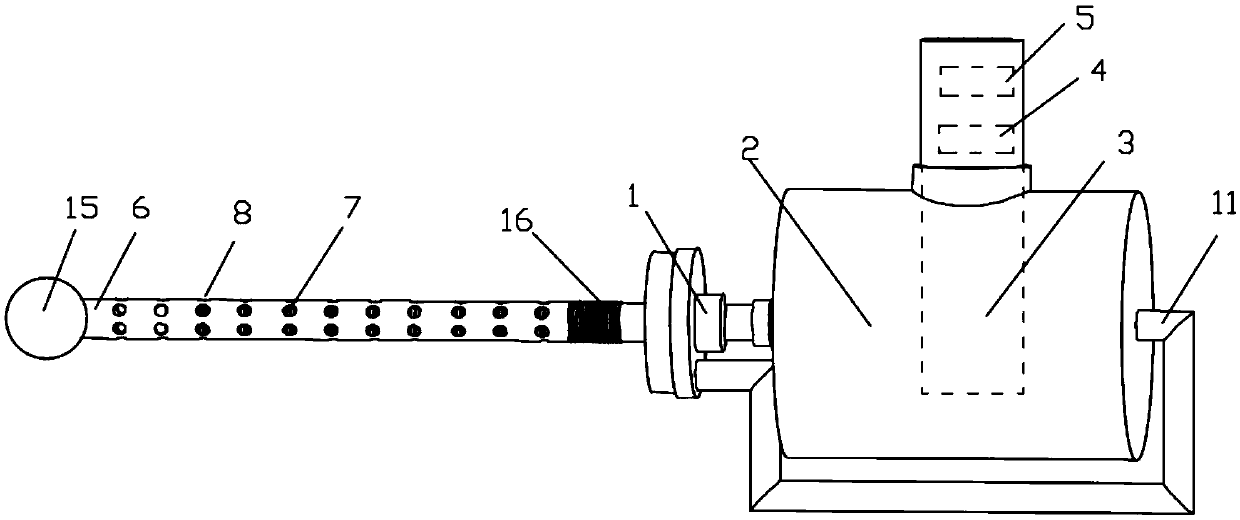

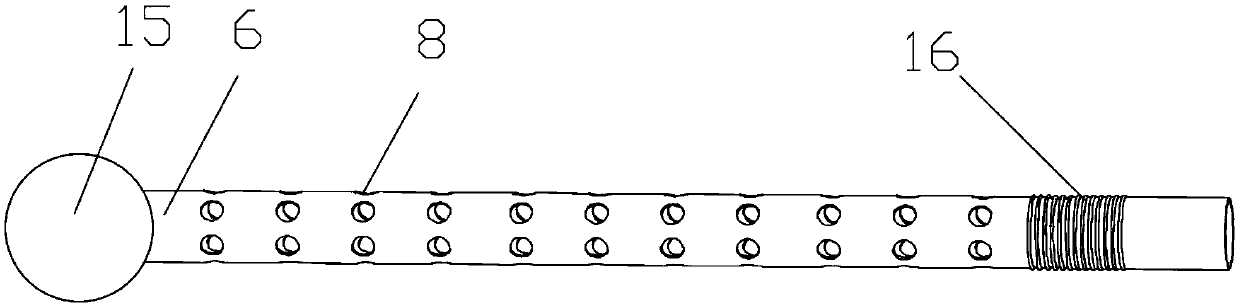

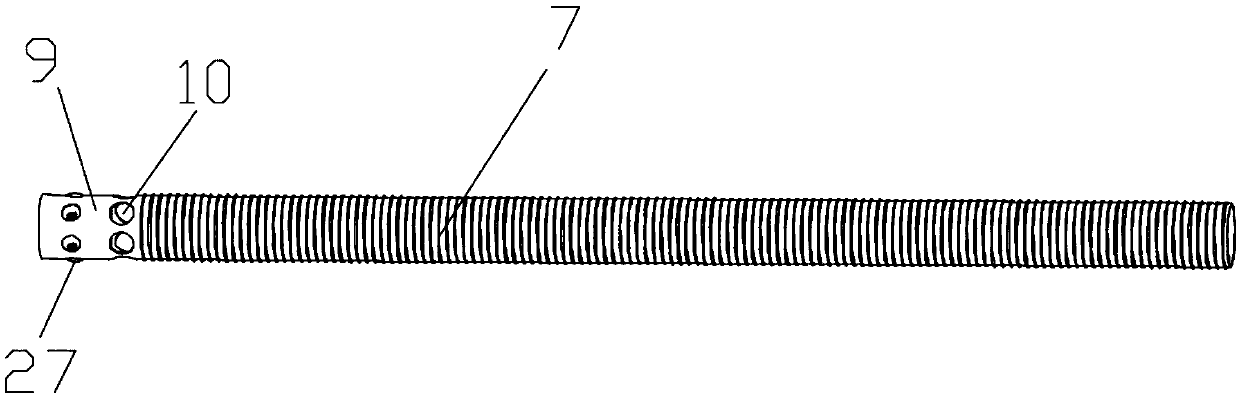

[0024] see Figures 1 to 4 , an on-line pressure regulating oil quality monitoring device, including a sampling tube, a sampling pump 1, a detection chamber 2, an oil sensor 3, a wireless module 4 and a processor 5; specifically, the oil sensor 3 includes a viscosity sensor and a density sensor Sensors for detecting the density and viscosity of the regulator oil. The sampling tube includes a support tube 6 and a flexible sampling hose 7 arranged in the support tube 6. Specifically, the wall of the flexible sampling hose 7 is formed by an extension steering wheel surrounding the flexible sampling hose 7. Constituted by twisted creases. The side of the support tube 6 is provided with a number of first oil inlet holes 8 equidistantly distributed, the two sides of the end of the telescopic sampling hose 7 are provided with second oil inlet holes 10 and the top is sealed by a plunger 9, the sampling The pump 1 injects the pressure-regulating oil to be tested into the detection ch...

Embodiment 2

[0030] see Figures 5 to 6 The difference between this embodiment and Embodiment 1 is that the telescopic sampling hose 7 communicates with the detection chamber 2 through the stirring chamber 17, and the pressure regulating oil coming in from the telescopic sampling hose 7 first passes through the stirring chamber 17, A first one-way valve 18 is provided between the telescopic sampling hose 7 and the stirring chamber 17, a second one-way valve 19 is provided between the stirring chamber 17 and the detection chamber 2, and a first one-way valve 19 is provided between the stirring chamber 17 and the detection chamber 2. The one-way valve 18 and the second one-way valve 19 prevent the pressure regulating oil from flowing backward, and the stirring chamber 17 is provided with a stirring blade 21, and the stirring blade 21 is driven by a first motor 23, and the first motor 23 is connected with the processing Device 5 is connected. Under the control of the processor 5, the first m...

Embodiment 3

[0033] see Figures 7 to 8 , The difference between this embodiment and Embodiment 2 is that the oil discharge port 11 is connected to the oil discharge chamber 29 through the third check valve 28, the third check valve 28 prevents the pressure regulating oil from flowing backward, and the oil discharge chamber 29 It is a hollow cylinder with a second piston 26 inside, and the piston reciprocates to suck in and discharge the pressure regulating oil. The oil discharge chamber 29 is provided with a linear motor 24 to push the second piston 26. Pushed by the motor 24 , the second piston 26 sucks in and discharges the pressure regulating oil. The oil discharge chamber 29 discharges oil through the oil discharge pipe 22 , and the oil discharge pipe 22 is provided with a pressure relief valve 20 . The pressure relief valve 20 maintains a certain pressure of the oil discharge pipe 22 so that the oil can be sprayed out from the oil discharge pipe 22 to avoid accumulation at the oil ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com