Automatic control system and construction method for sand box unloading

An automatic control system and control system technology, applied in the direction of control/adjustment system, non-electric variable control, electric speed/acceleration control, etc., can solve the difficulty of unloading speed control, difficulty in ensuring synchronization, complicated inspection procedures, etc. problem, to achieve the effect of fine unloading speed control, high degree of automation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

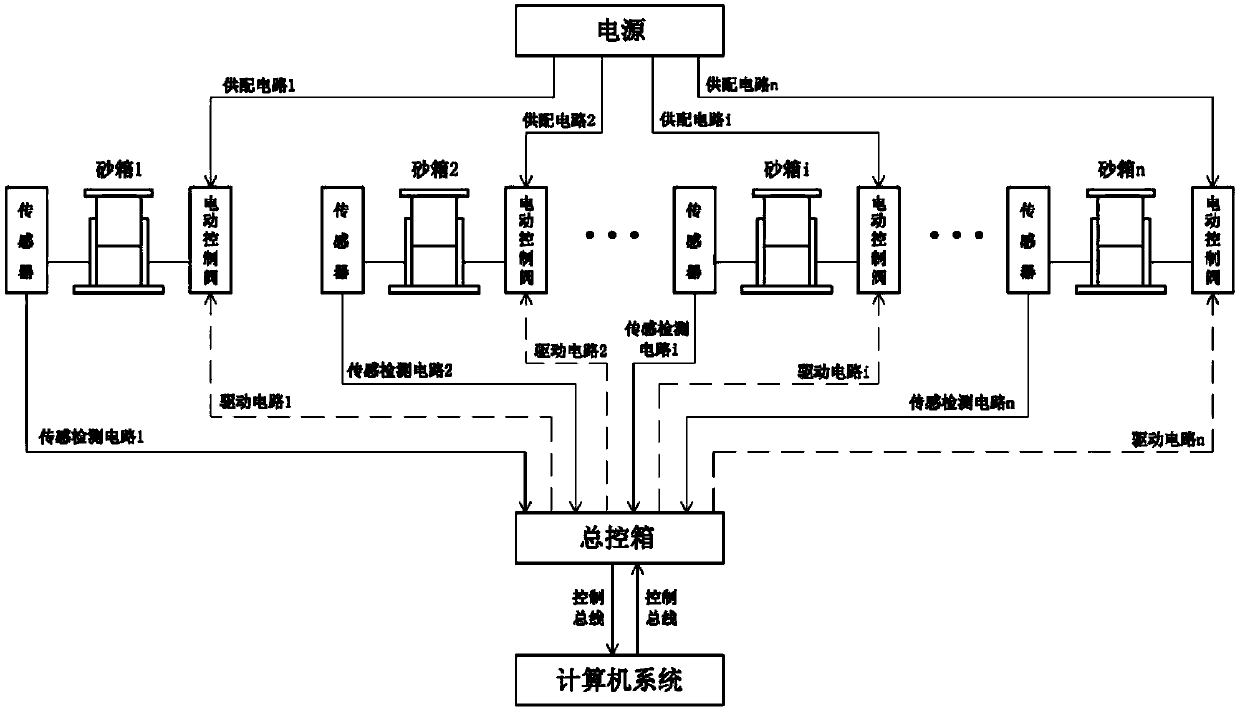

[0033] An automatic control system for sand box unloading, including a sand box, an electrical control system and a computer control system;

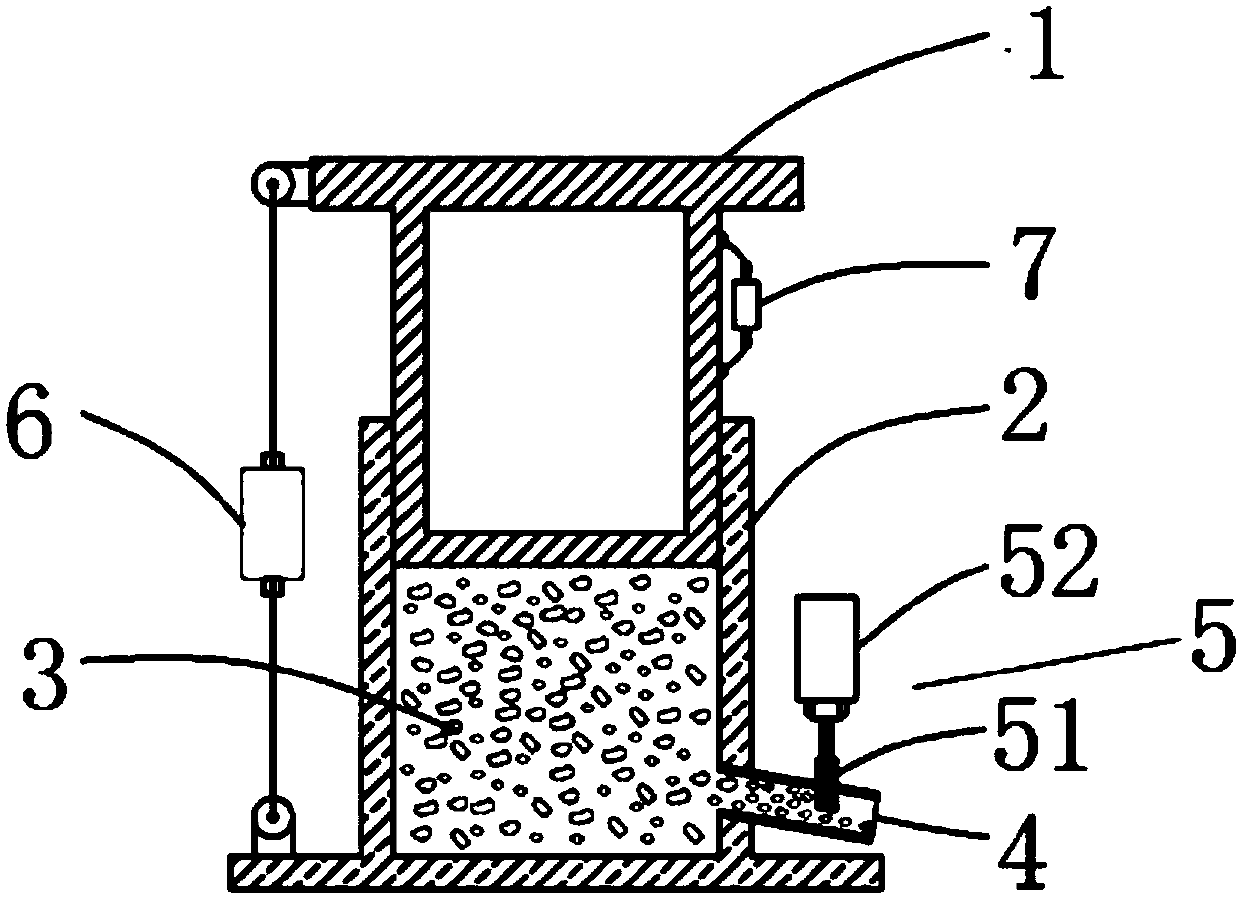

[0034]The sand box is composed of an upper section 1, a lower section 2, dry sand 3, and an electric sand discharge valve 5: the upper section 1 and the lower section 2 are cylinders, and the upper section 1 is nested in the lower section 2, the outer wall of the upper section 1 is closely attached to the inner wall of the lower section 2; the lower section 2 is filled with dry sand 3, and the bottom of the cylinder is provided with a sand discharge pipe 4; the effect of the structural pressure supported by the upper section 1 on its upper part Next, the dry sand 3 in the lower section cylinder 2 is extruded and discharged through the sand discharge pipe 4 and the electric sand discharge valve 5, and the upper section cylinder 1 is gently lowered, thereby completing the unloading of the structure; the electric sand discharge valve 5 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com