Fertilizer pelletizer

A granulator and granulation technology, applied in the direction of extrusion and granulation of raw materials, can solve the problems of uneven granulation of fertilizers, affecting the growth of crops, etc., and achieve the effects of uniform size, less driving mechanism and less energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is further described in detail through specific implementation methods:

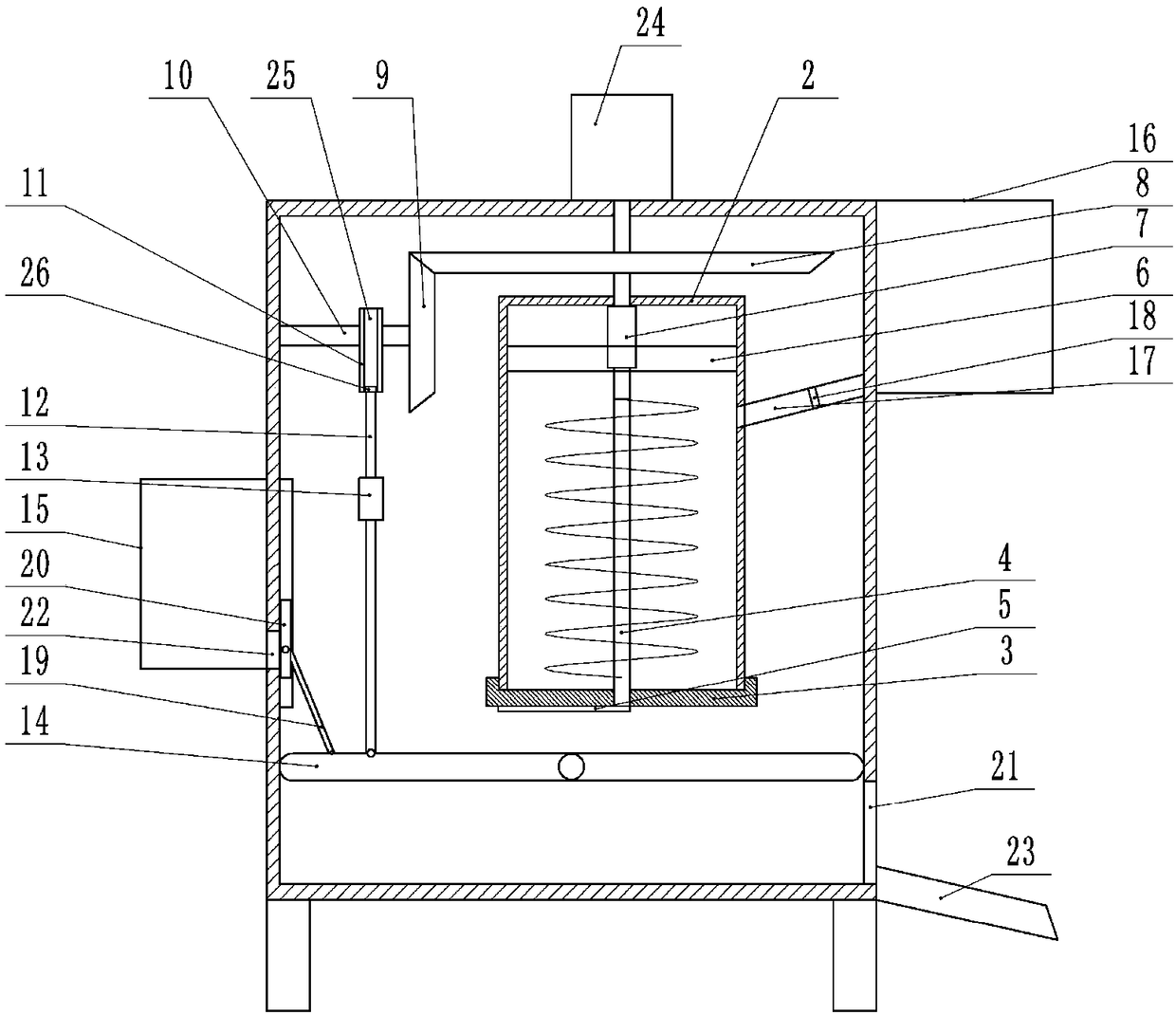

[0019] The reference signs in the accompanying drawings of the description include: cabinet 1, granulation barrel 2, granulation plate 3, screw feed rod 4, blade 5, push plate 6, cylindrical cam 7, first bevel gear 8, second bevel gear 9 , horizontal shaft 10, cam 11, ejector rod 12, casing 13, corrugated plate 14, powder box 15, storage barrel 16, conduit 17, one-way valve 18, pole 19, cover plate 20, discharge port 21 , discharge port 22, discharge plate 23, motor 24, chute 25, slide block 26.

[0020] like figure 1 Shown, a kind of fertilizer granulator, comprises chassis 1, combines figure 2 As shown, the cabinet 1 is provided with a granulation barrel 2 with an open lower end, the lower end of the granulation barrel 2 is threadedly connected with a granulation plate 3, the granulation plate 3 is evenly distributed with granulation holes, and the granulation barrel 2 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com