An automatic sandblasting machine for the inner wall of a pipeline

A sand blasting machine, steel pipe inner wall technology, applied in the direction of abrasive jetting machine tools, spray guns, manufacturing tools, etc., can solve the problems of low automation, human body and environmental hazards, large floor area, etc., and achieve high automation and protection against hazards , The effect of low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings in the embodiments of the present invention.

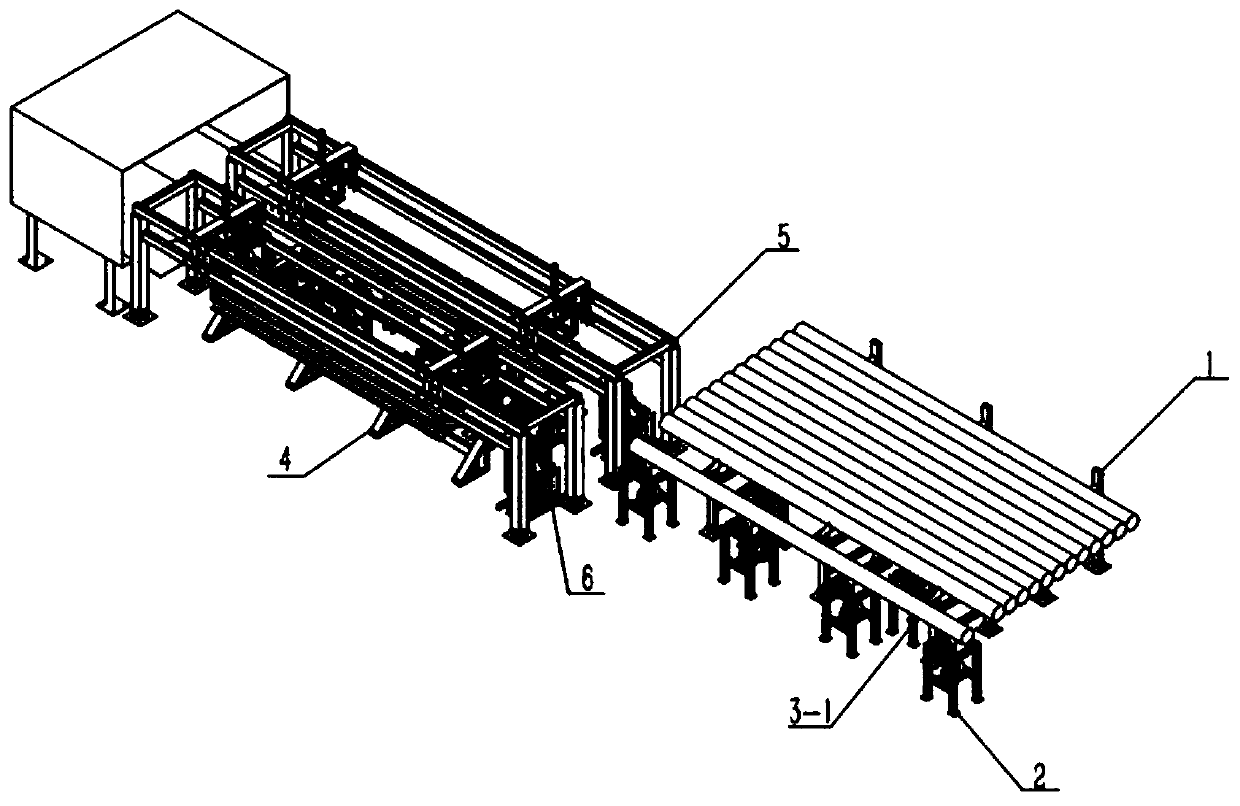

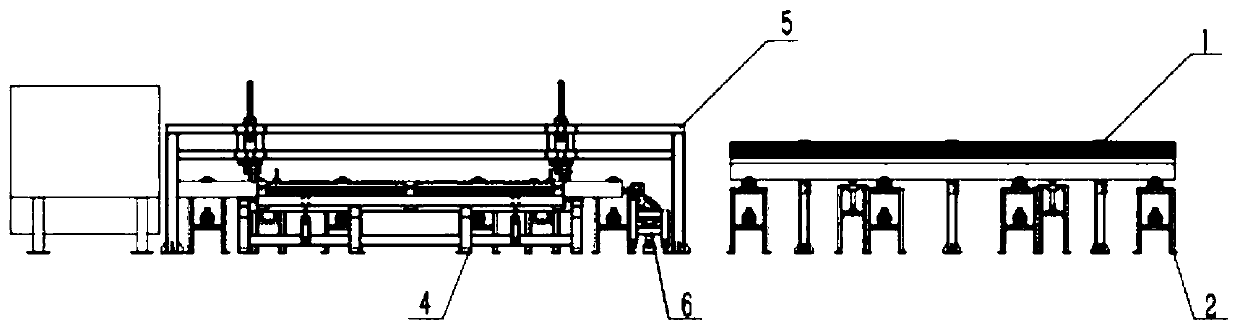

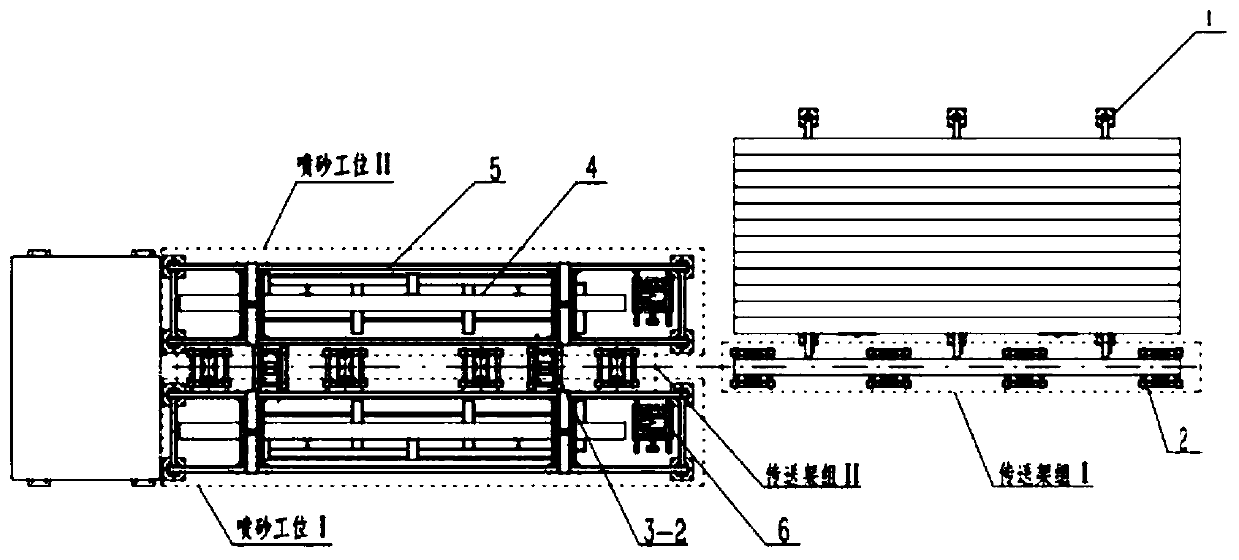

[0031] Such as Figure 1~4 As shown, an automatic sandblasting machine for the inner wall of a pipeline includes a storage device 1 , a conveying device 2 , a feeding device 3 , a V-shaped bracket 4 , a pipe rotation driving device 5 , and a sandblasting device 6 .

[0032] The storage device 1 is made up of 3 storage racks 7, which are placed side by side and equidistant, and are used to place the steel pipes to be processed; as Figure 5 As shown, the storage rack 7 is a trapezoidal steel frame 8 formed by welding structural steel, and its shape is a right-angled trapezoid. The height-adjustable stop piece 9 is housed on the 8, in order to limit the steel pipes of different pipe diameters.

[0033] The conveying device 2 is composed of 8 conveying racks 10, arranged in a row at equal intervals, and divided into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com