Biological membrane multistage reaction equipment

A multi-stage reaction and biofilm technology, applied in the field of sewage treatment, can solve problems that threaten the health of farmers, damage the rural ecological environment, and hinder rural economic development, and achieve cost savings, increased walking length, and improved treatment scale. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

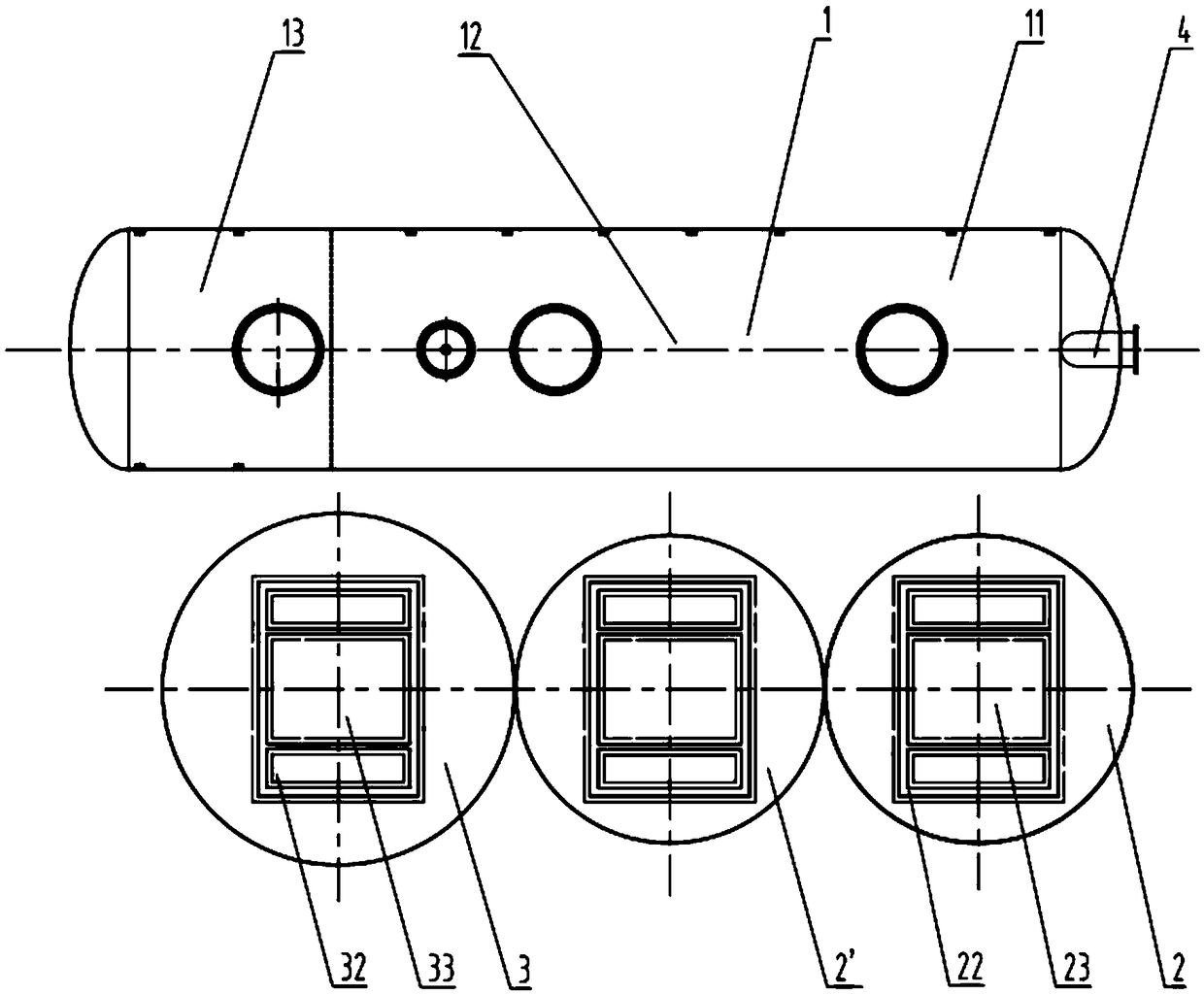

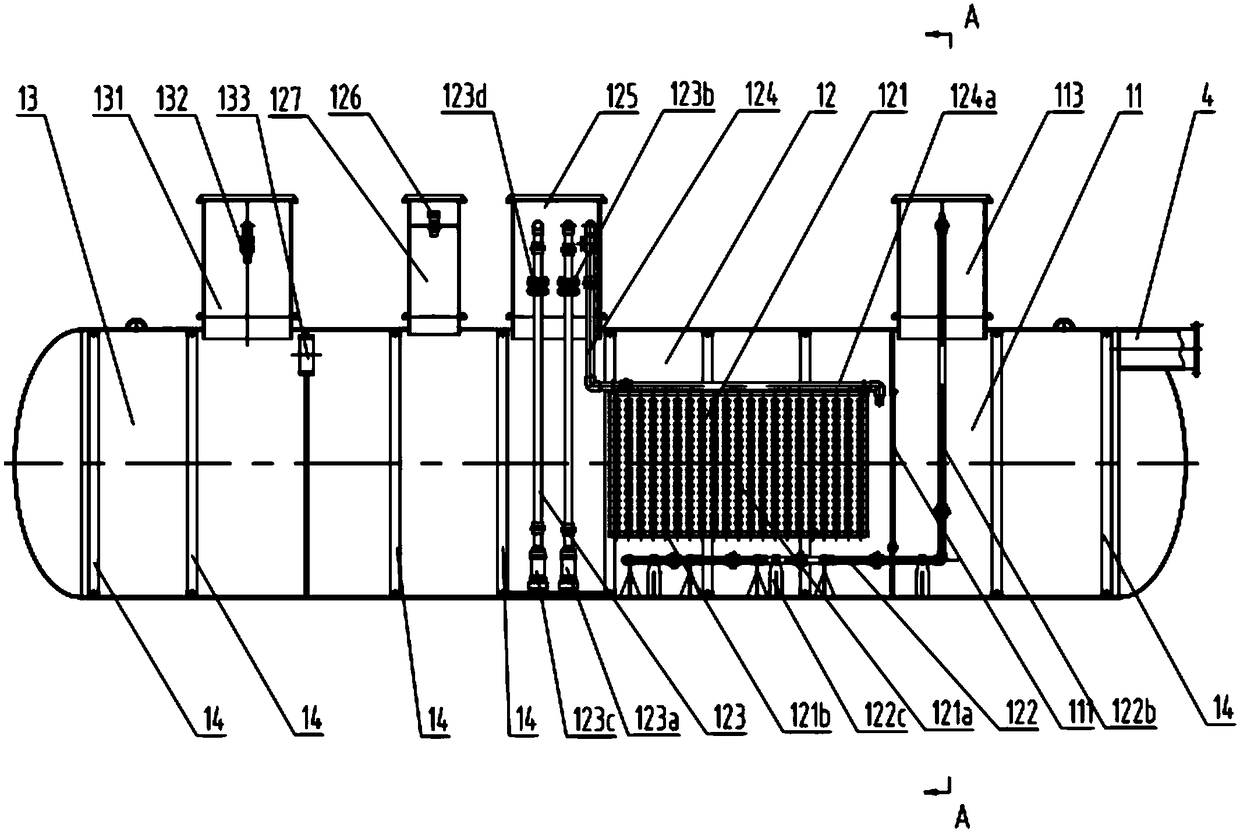

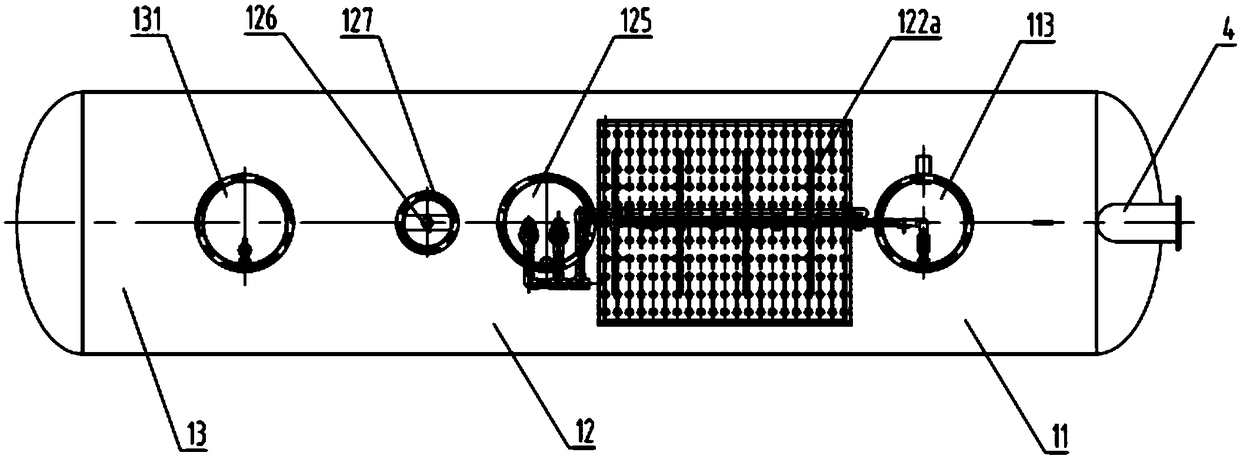

[0052] Such as Figure 1-12 As shown, a biofilm multistage reaction equipment includes a comprehensive integrated device 1 and a vertical multistage biochemical device; the vertical multistage biochemical device includes two serially connected first biochemical tanks 2 and second biochemical tanks 2' and sedimentation tank 3; the sewage enters the comprehensive integrated device 1 sequentially through the peripheral water pipeline, the first biochemical tank 2, the second biochemical tank 2' and the sedimentation tank 3; according to drainage standards or sewage treatment capacity or other factors , one or more biochemical tanks can be connected in series or in parallel between the integrated device and the settling tank, when multiple biochemical tanks are connected in series between the integrated device and the settling tank , different biochemical tanks are sequentially loaded with different fillers according to the sewage treatment requirements, and the sewage can be repe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com