Drying device used for lithium battery production technology

A technology of production process and baking device, which is applied in the manufacture and drying of non-aqueous electrolyte batteries and electrolyte batteries, which can solve the problems of uneven heating, large heat loss, and low efficiency, and achieve fast heating efficiency and small heat loss , the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings, in which the same reference numerals represent the same components. In order to keep the drawings concise, each drawing only schematically shows the parts related to the invention, and they do not represent the actual structure of the product.

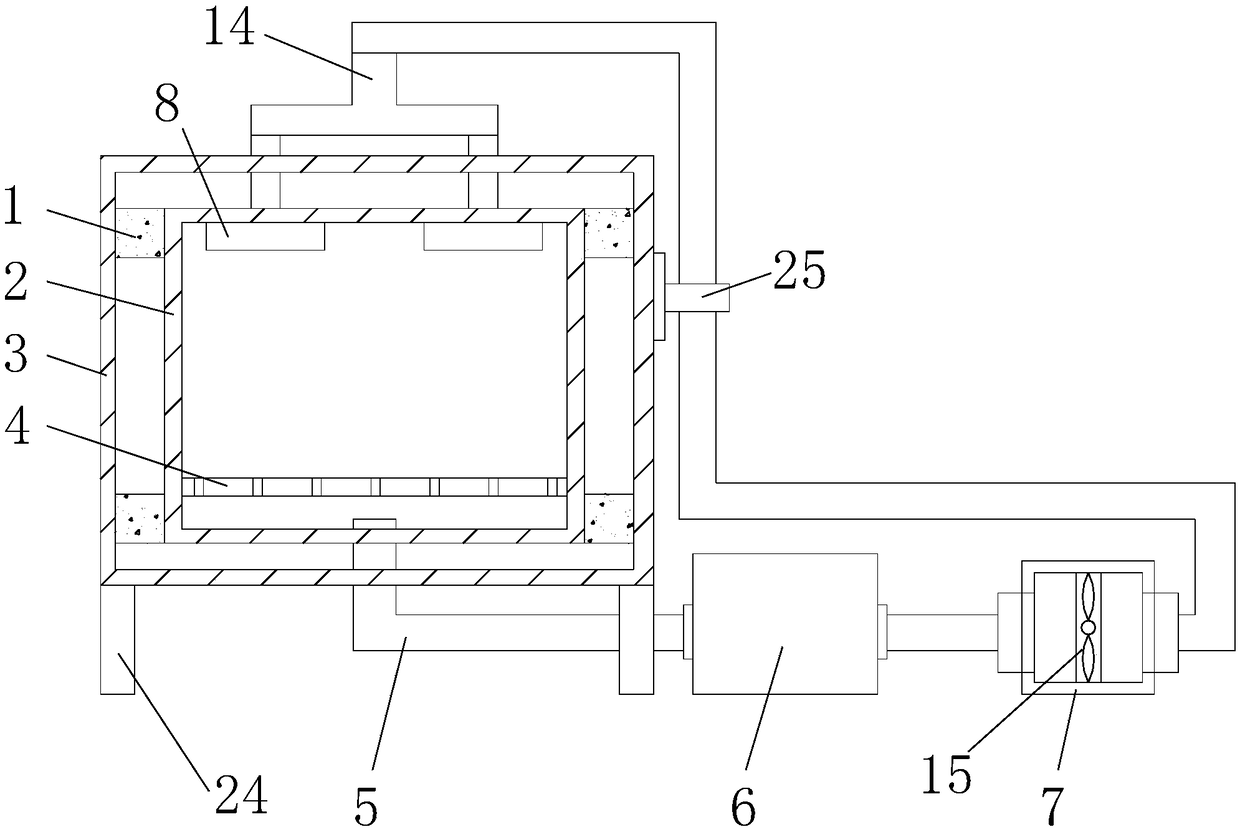

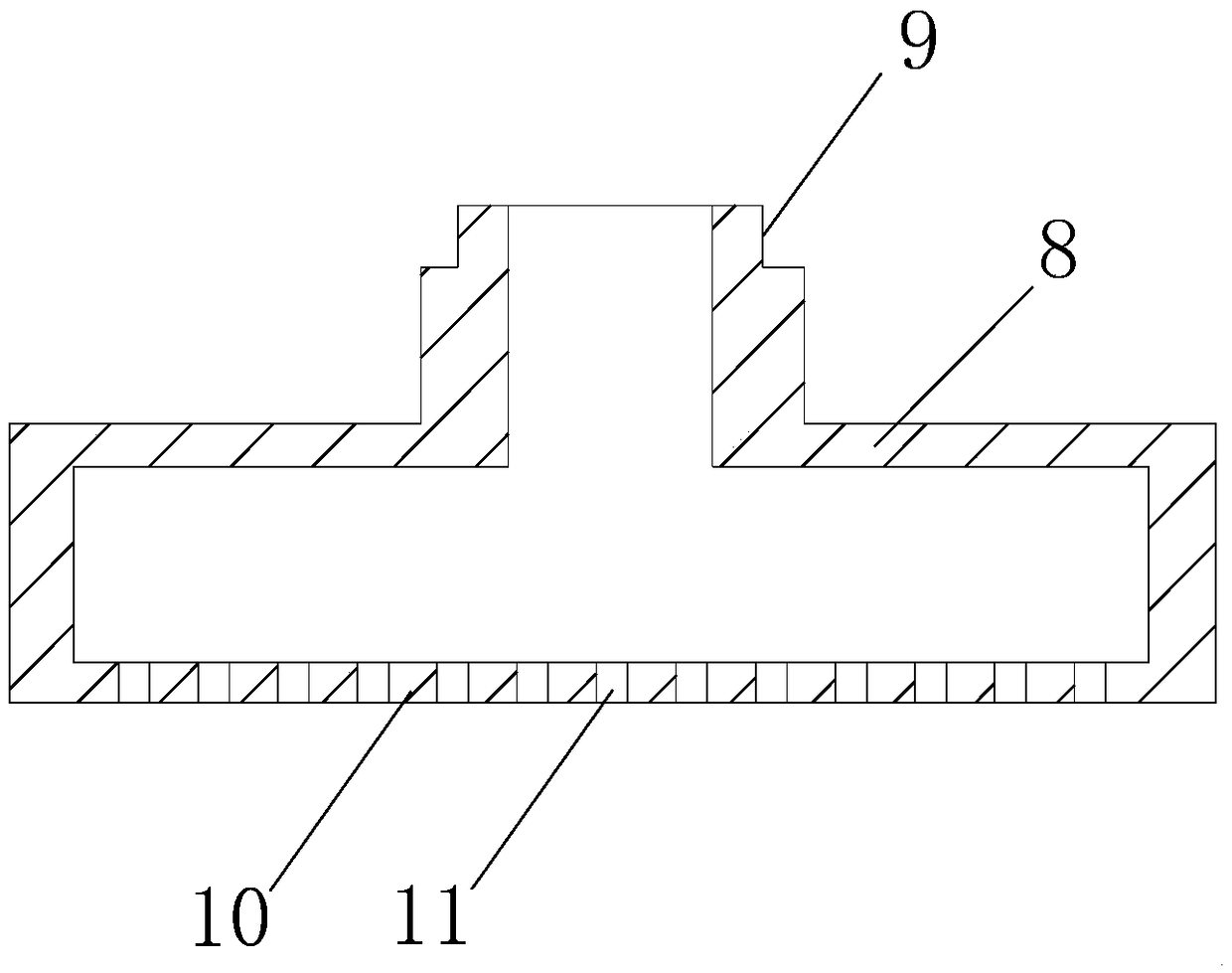

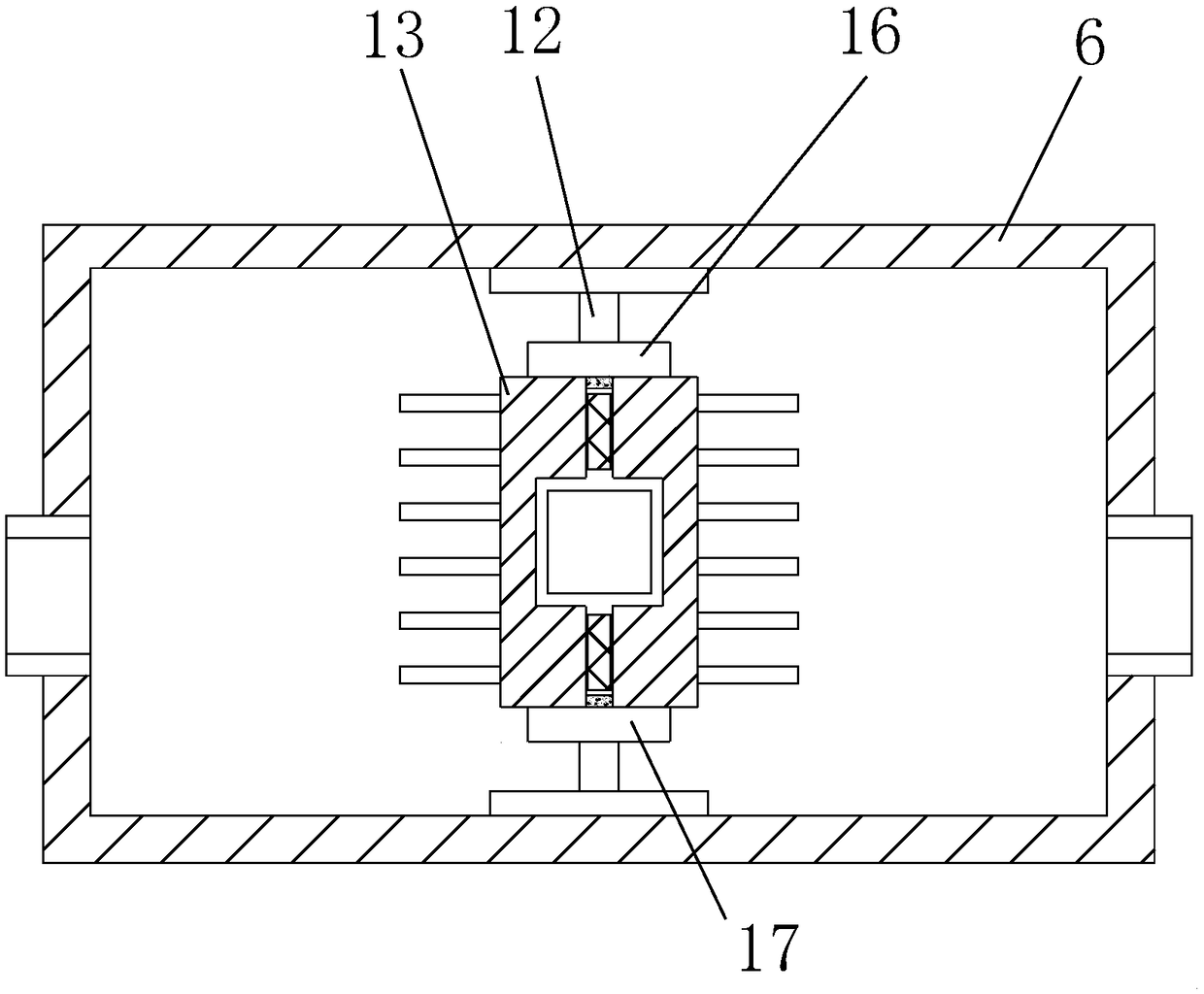

[0020] Such as figure 1 , 2 , 3, 4, and 5, the present invention is a baking device for a lithium battery production process, including a device housing 3, the device housing 3 is connected to the baking oven 2 through a connecting column 1, and the baking oven 2 The top is provided with an air intake system, the middle and lower part of the oven 2 is provided with a support plate 4 with through holes, and the bottom of the oven 2 is provided with an air outlet pipe 5; The gas system is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com