Sliding bearing-rotor system unbalance amount recognition method

A sliding bearing and identification method technology, applied in static/dynamic balance testing, character and pattern recognition, measuring devices, etc., can solve the problems of serious time-consuming, low efficiency, etc. small impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

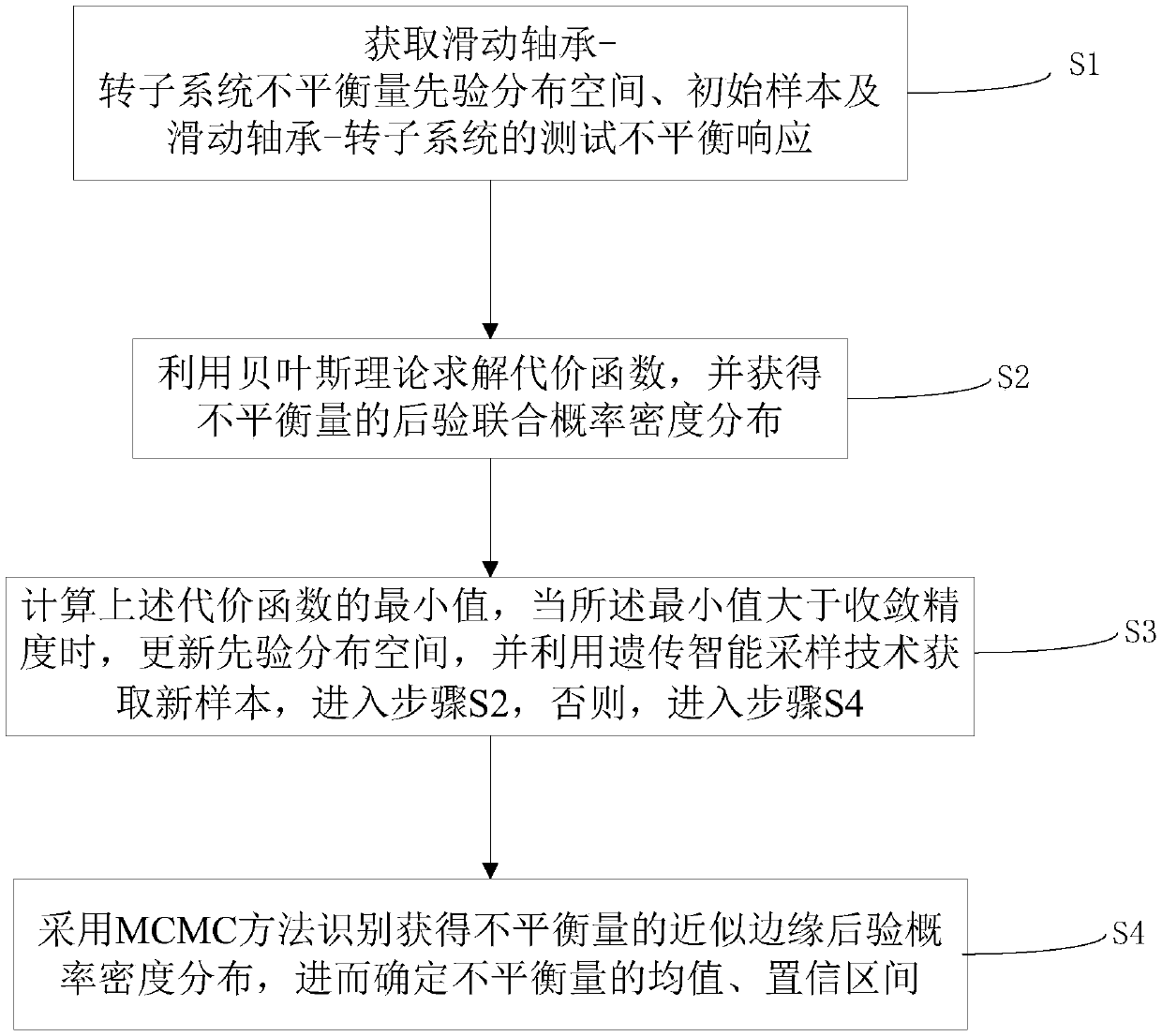

[0051]In order to use the sample information of the sliding bearing-rotor system service environment changes, the limitations of test conditions and the uncertain factors in the sliding bearing-rotor system information to reduce the uncertain factors in the application of sliding bearing-rotor dynamic balance Influence on the identification result of unbalanced quantity. On the other hand, the pre-estimation information of the unbalance parameters based on the experience and knowledge of the engineer before the experimental measurement information is obtained is used to improve the recognition accuracy of the unbalance. In this embodiment, Bayesian theory and MCMC method, which can deal with sample information of uncertain factors and prior information of unbalanced quantities, are used to obtain the mean value and confidence interval of unbalanced quantities. Aiming at the computational efficiency of Bayesian theory in the identification of bearing-rotor system unbalance, a m...

Embodiment 2

[0096] In this embodiment, the method in Example 1 is verified through specific experiments,

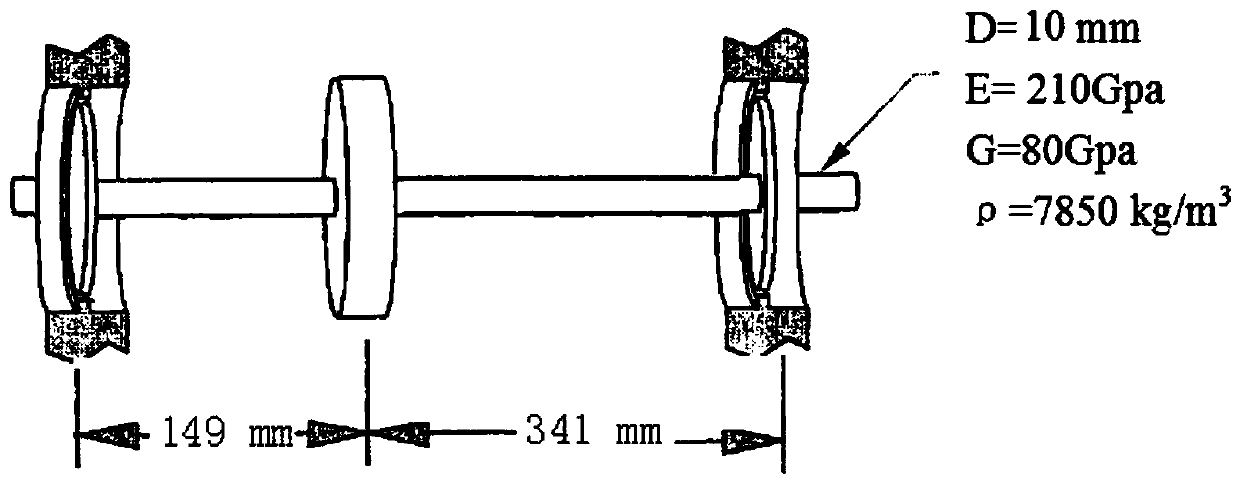

[0097] First, establish the rotor bearing system model

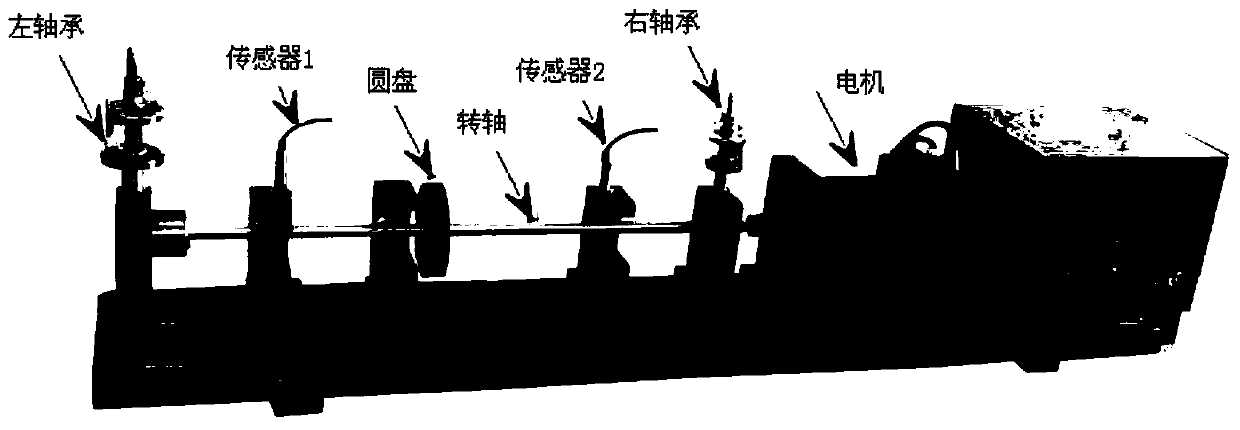

[0098] Such as figure 2 Shown is the INV1612 rotor test bench as the test model of the method in Example 1. The thickness of the disk is 15mm, and 16 holes are distributed along the circumference at the diameter of 60mm. Screws of different weights can be configured to artificially set the unbalanced mass. Both ends of the rotor are supported by sliding bearings, and their oil film characteristic coefficients are shown in Table 1. The rotational speed is designed to be 2000r / min.

[0099] Table 1 Oil film stiffness and damping coefficient of sliding bearing

[0100]

[0101] Table 2 Midpoints and intervals of uncertain variables

[0102]

[0103] Then, according to the method in embodiment 1, carry out unbalance amount identification;

[0104] In order to avoid errors caused by cross-coupling of the magnetic field o...

Embodiment 3

[0108] After identifying the unbalanced amount of the rotor through the above embodiments, the rotor can be directly dynamically balanced to solve the unbalanced rotor caused by various factors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com